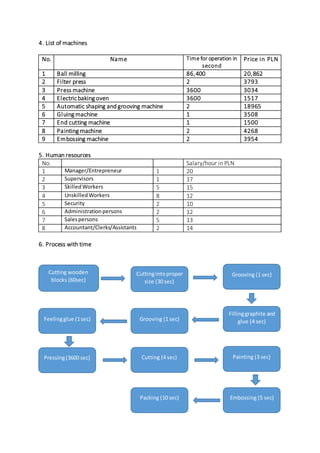

This document provides information for the pencil manufacturing process, including necessary data, guidelines, manufacturing steps, machinery list, human resources, and process timeline. It details the nine main steps of cutting wood into slats, treating and grooving slats, inserting graphite cores, gluing sandwich slats together, trimming and shaping pencils, painting and printing, adding erasers and caps, and final packing. Machinery names, operation times, and prices are listed. The human resources section outlines number of employees by role and their hourly salaries. The process timeline outlines each step and estimated completion times.