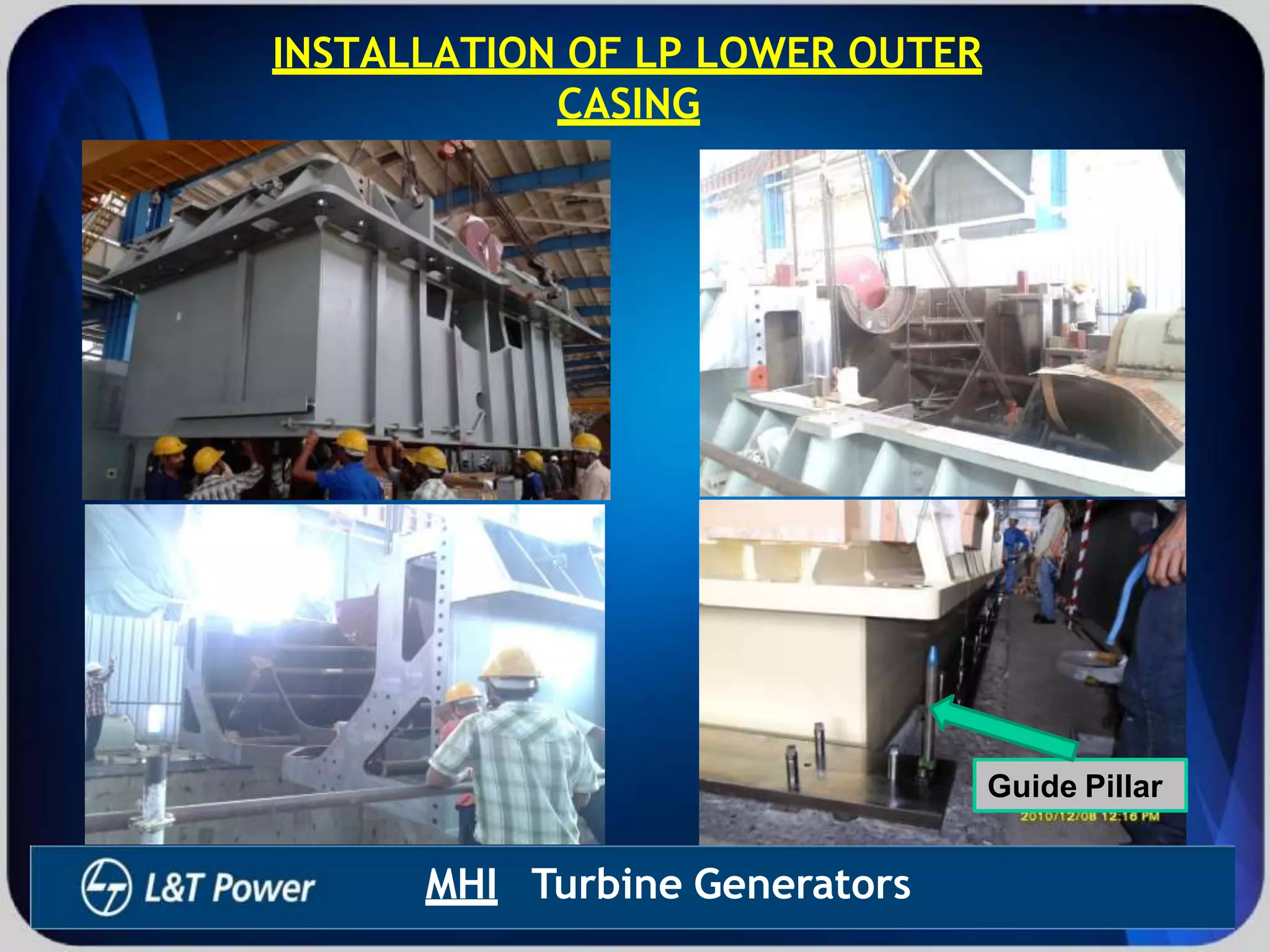

This document provides an overview of turbine erection training conducted at the 2x700 MW Rajpura Thermal Power Plant in Punjab, India from June 20th to August 10th, 2013. It outlines the 12 step turbine erection flow chart that was followed, including centering the turbine foundation, installing components like the LP outer casing and HIP module, installing bearings and rotors, final assembly procedures, grouting, and oil flushing. The training aimed to teach trainees how to properly erect and align the turbines according to specifications.