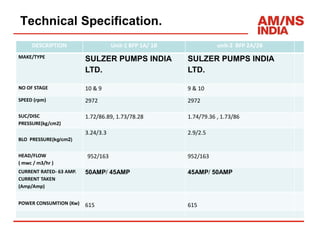

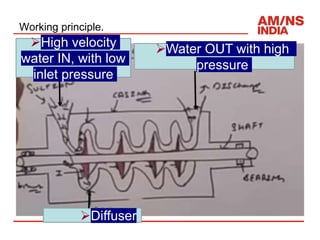

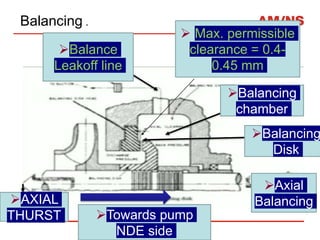

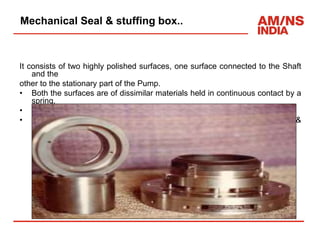

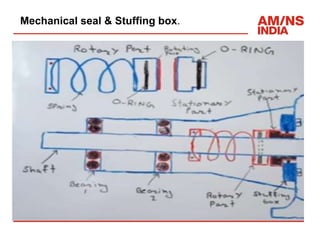

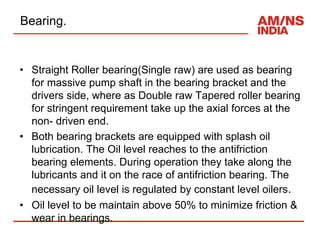

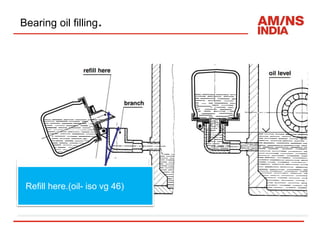

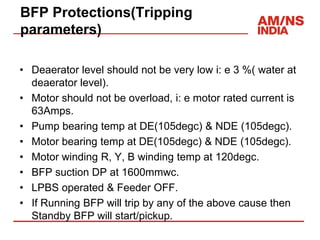

The document provides an overview of boiler feed pump operation and troubleshooting. It discusses key components like the balancing drum and leak off line which help balance axial thrust on the pump rotor. Minimum recirculation lines are used to maintain flow through the pump at low loads. Mechanical seals and bearings are important for preventing leakage and reducing friction. Protections like motor overload and high temperature trips ensure safe operation of the boiler feed pump.