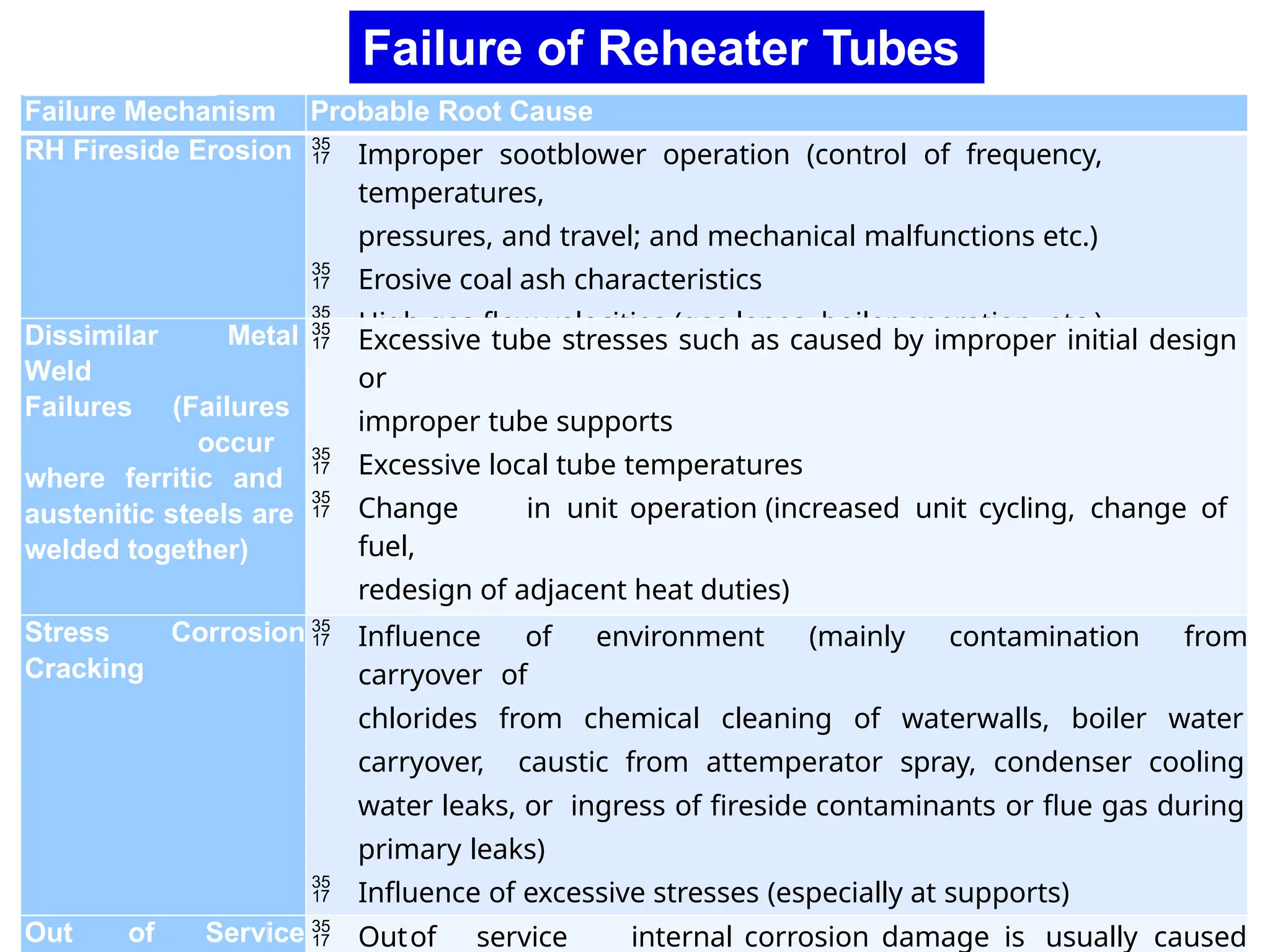

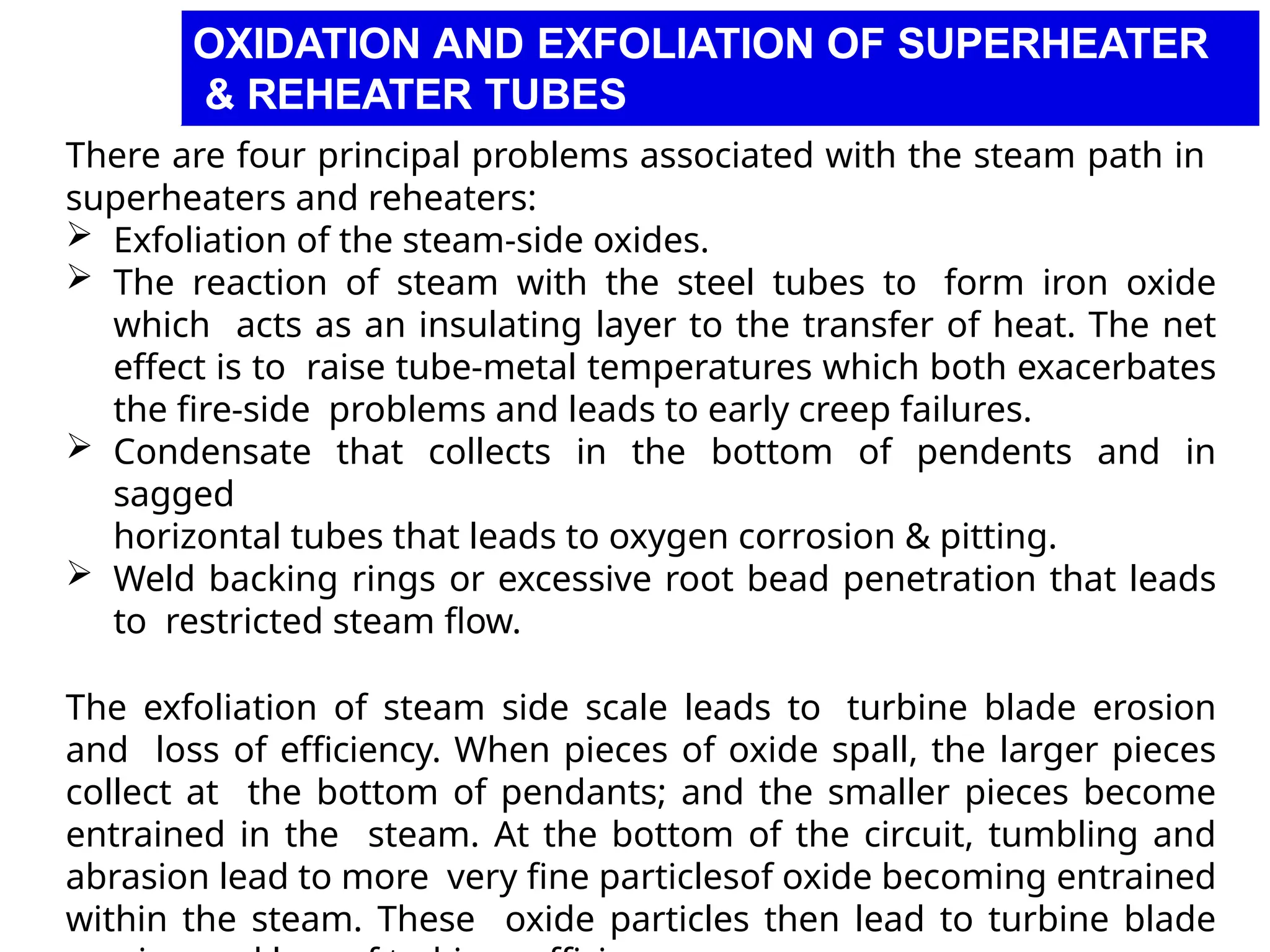

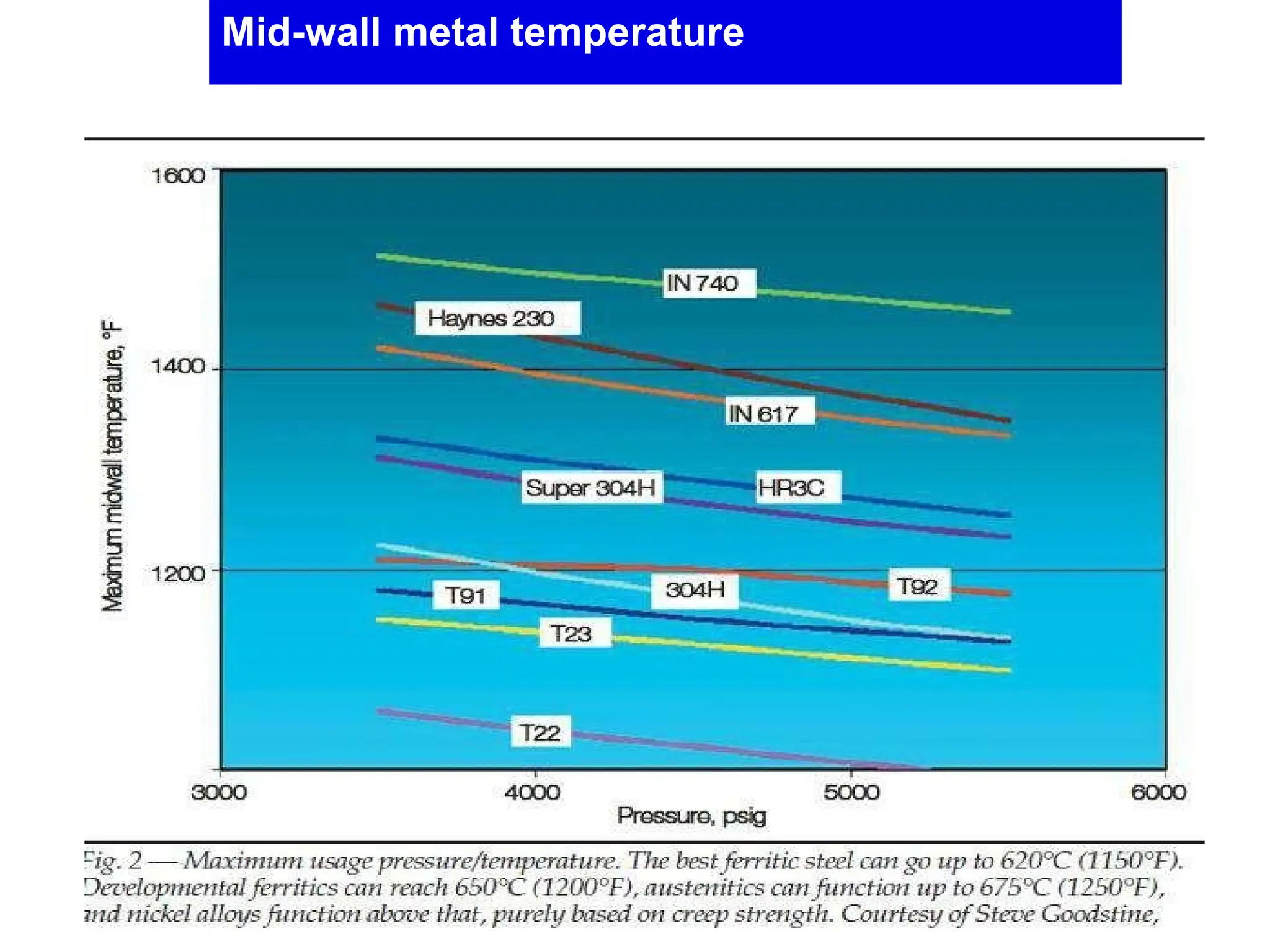

The document discusses the failure mechanisms of reheater tubes, identifying various probable root causes such as short-term and long-term overheating, corrosion, and improper operational practices. It highlights factors leading to oxidation, exfoliation of steam-side oxides, and issues related to material choices and system design. The document emphasizes the impact of variable operational conditions and requires a control strategy for maintaining tube integrity to prevent catastrophic failures.