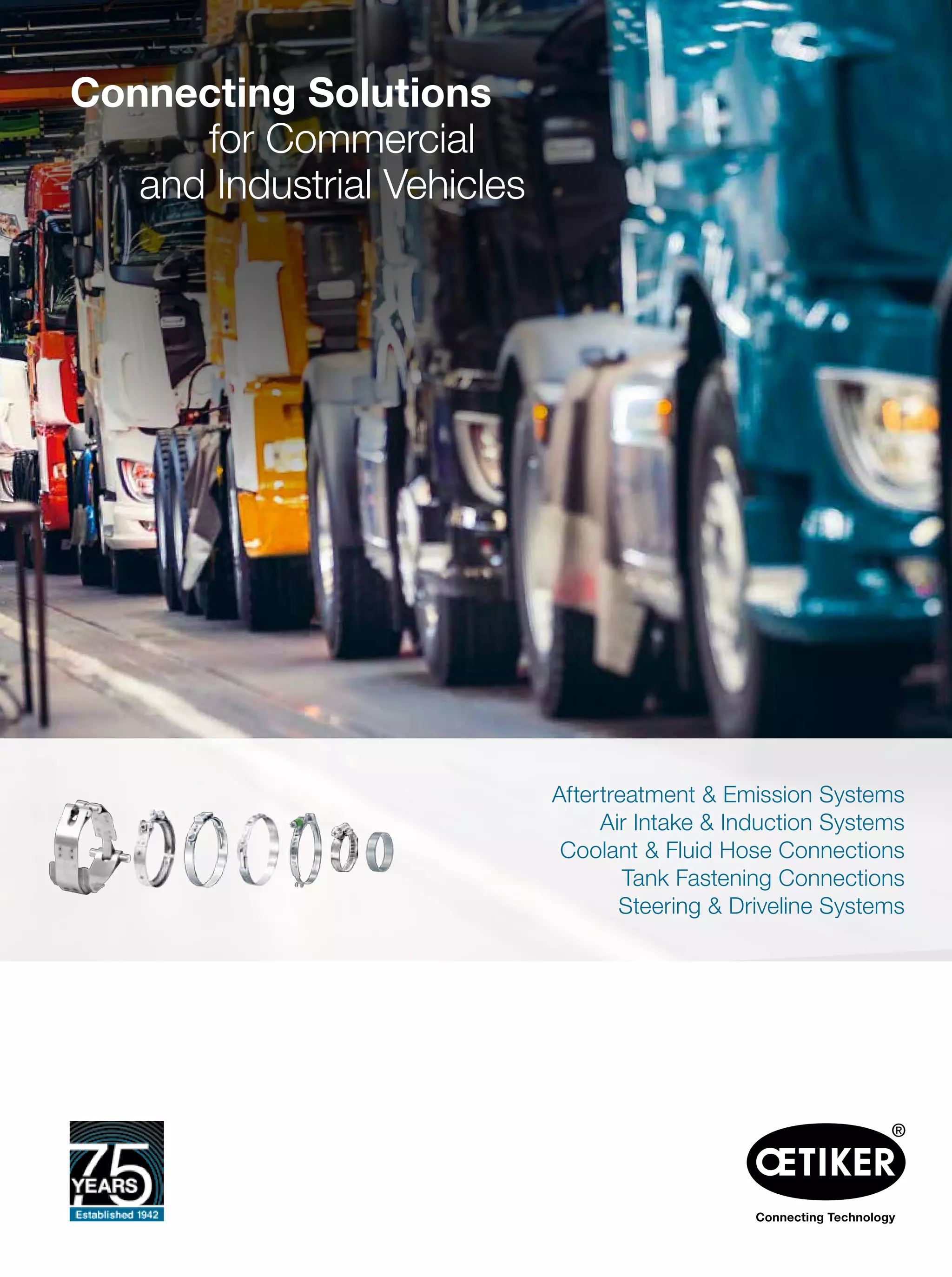

Oetiker is a global manufacturer specializing in OEM connecting solutions for commercial and industrial vehicles, providing products like clamps and connectors that ensure reliability under extreme conditions. Their 360° solution approach encompasses design, testing, and customer-specific engineering, with a commitment to meeting stringent emissions regulations and improving vehicle performance. With over 75 years of experience, Oetiker manufactures nearly 2 billion products annually, confirming quality across more than 90 million vehicles.