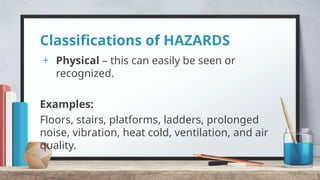

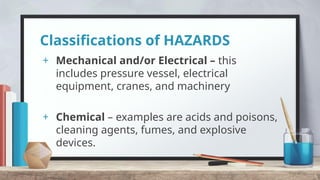

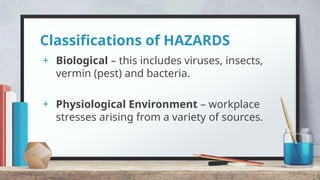

The document outlines the principles of occupational safety and health (OSH), focusing on hazard identification, risk assessment, and risk control to prevent workplace injuries and illnesses. It classifies hazards into physical, mechanical/electrical, chemical, biological, and physiological categories. Additionally, it introduces the 5S approach from Japan, which aims to enhance workplace efficiency and quality through sorting, organizing, cleaning, standardization, and sustaining practices.