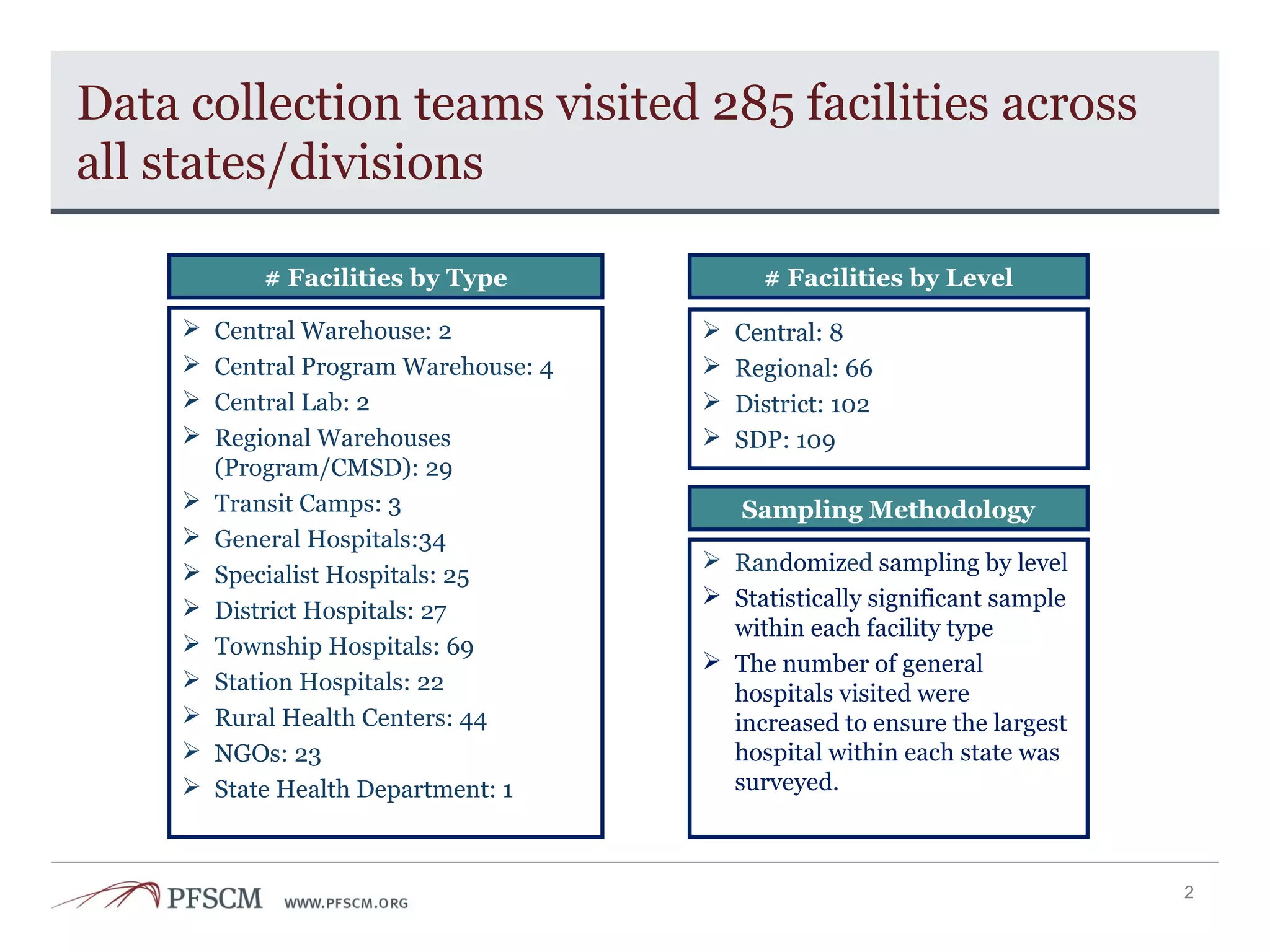

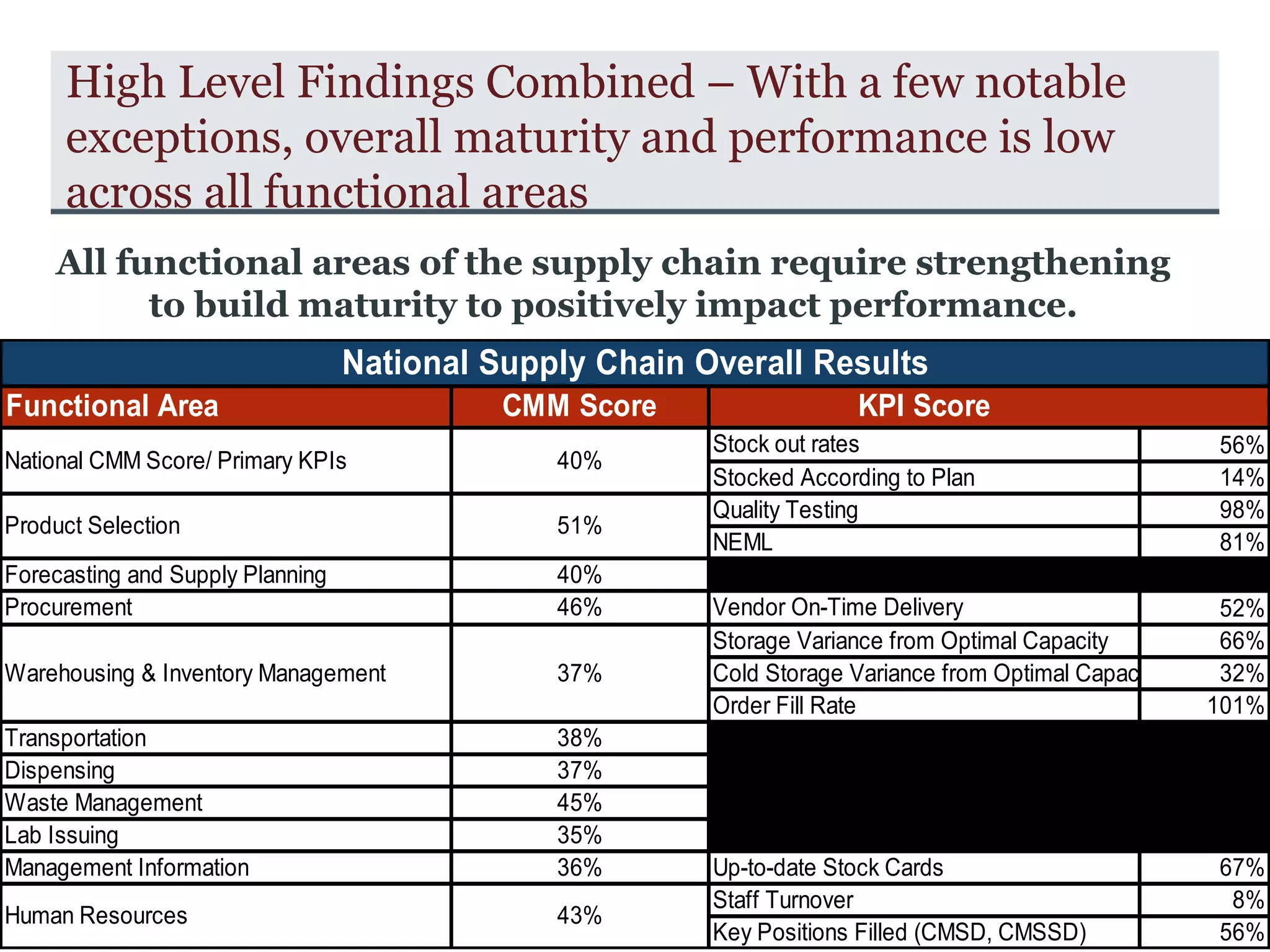

The document summarizes the findings of a national supply chain baseline assessment conducted in Myanmar in 2014 by the Ministry of Health and partners. The assessment aimed to provide an evidence-based understanding of the supply chain to guide strengthening efforts. Data was collected from 285 facilities across all levels of the health system and analyzed. Overall, the findings showed that maturity and performance across functional areas of the supply chain were low, requiring strengthening in order to positively impact the supply chain. Specific key performance indicators such as stockout rates, stock accuracy, and order fill rates demonstrated needs for improvement.