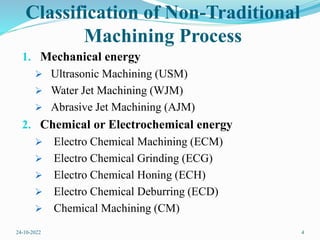

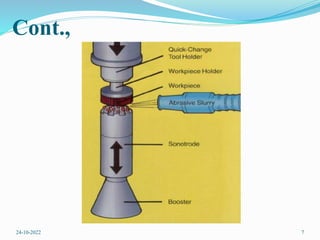

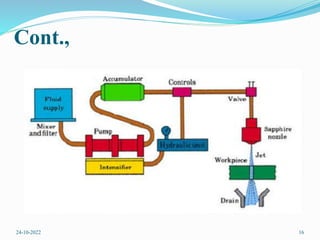

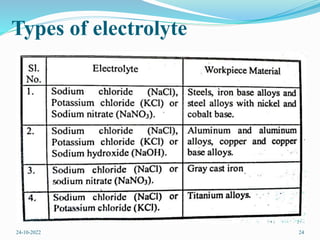

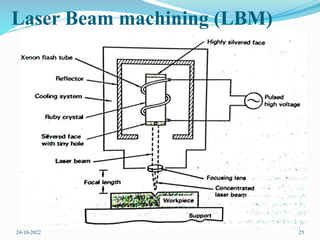

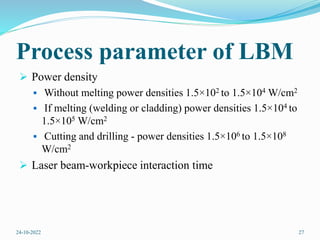

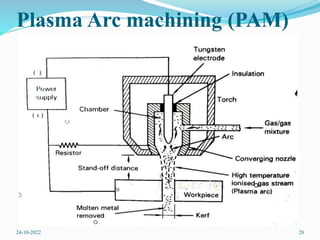

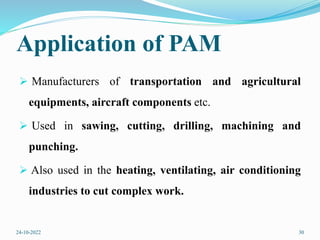

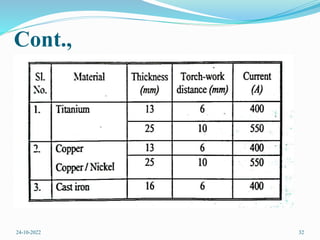

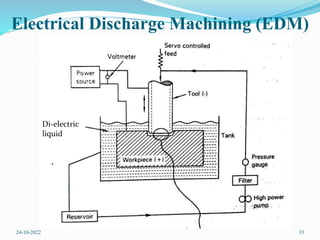

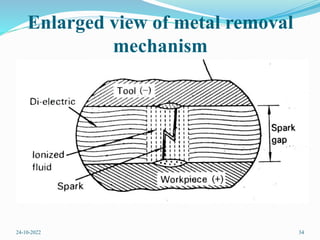

This document discusses various non-traditional machining processes. It begins by explaining that non-traditional machining is used when workpiece materials are too hard or complex shapes are required. It then classifies non-traditional machining into three categories: mechanical energy processes like ultrasonic machining; chemical/electrochemical processes like electrochemical machining; and thermal/electrothermal processes like laser beam machining. For each process, it provides a brief overview and discusses applications and key process parameters.