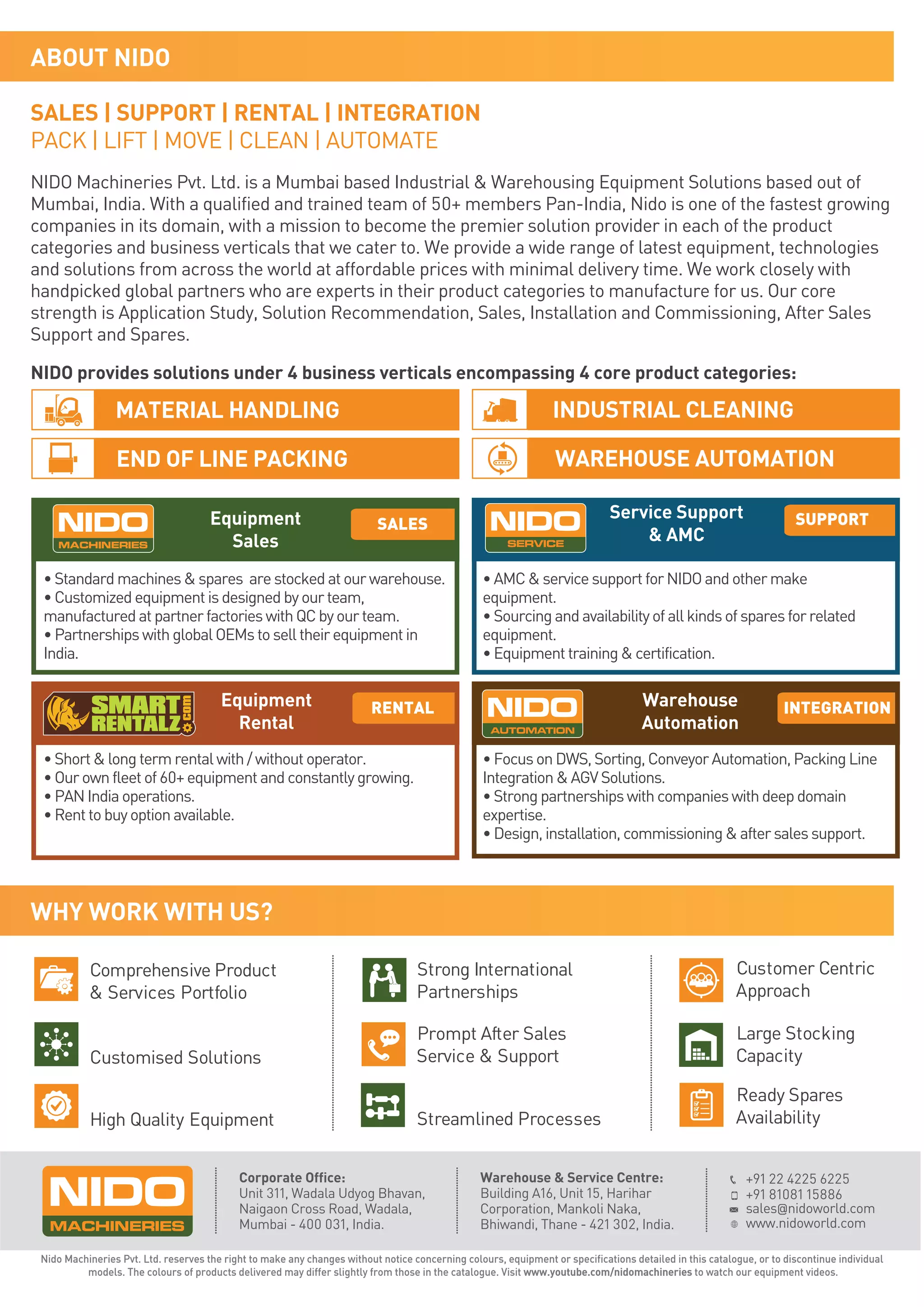

Nido Machineries provides warehouse automation solutions including dimensioning, weighing, scanning systems, sorters, conveyors, automated guided vehicles, and packaging line integration. It offers sales, support, rental, and integration of these solutions. Key industries served include e-commerce, logistics, courier, automotive, retail, and manufacturing. The company has partnerships with global equipment manufacturers and provides design, installation, commissioning, and after-sales support across India.