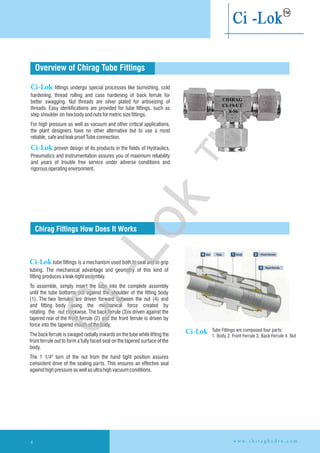

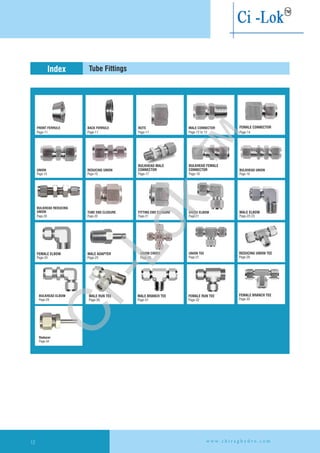

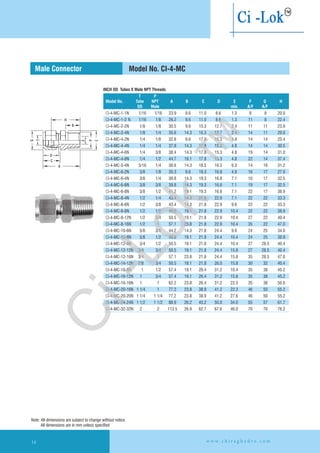

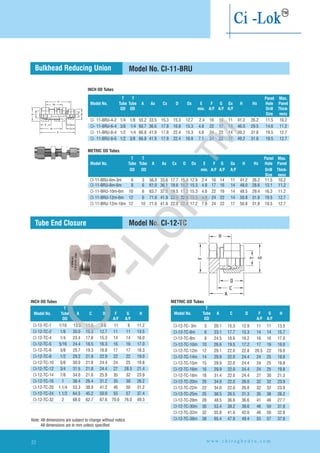

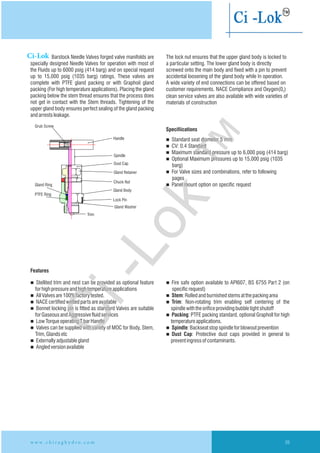

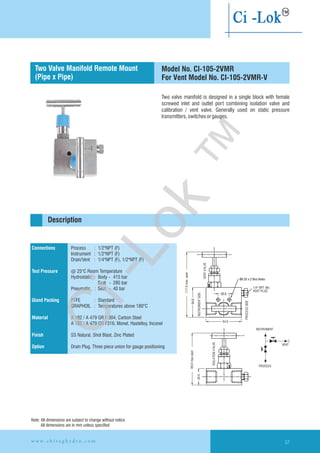

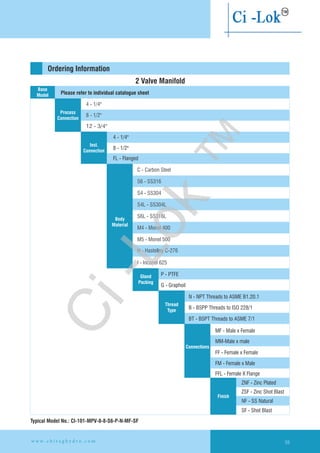

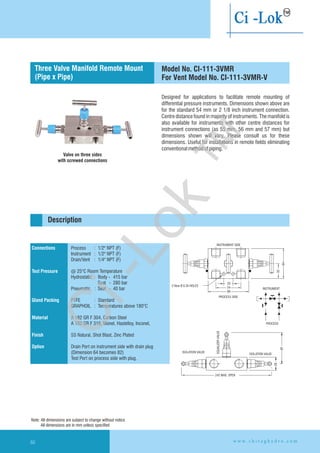

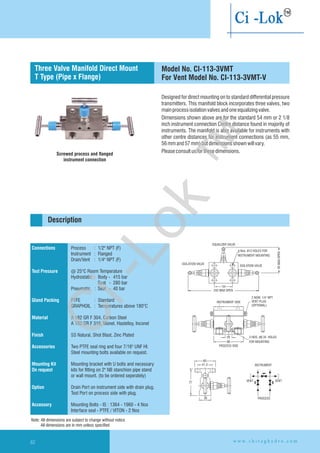

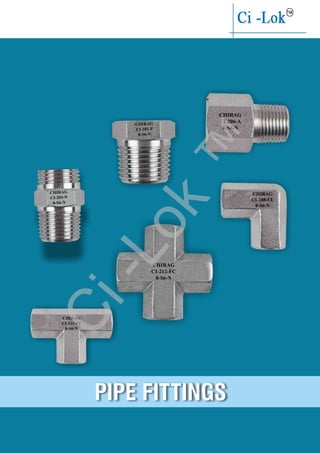

Chirag Industries manufactures valves, manifolds, needle valves, tube fittings, pipe fittings, and ball valves for industries such as oil and gas, petrochemicals, power generation, pharmaceuticals, and more. The company is ISO 9001:2008 certified and located in Mumbai, India. It provides a wide range of products and services to meet customer needs and strives for continuous innovation, commitment to customers, and high quality through certification and testing of materials. The document provides an overview of Chirag's Ci-Lok tube fittings, how they work to create a leak-tight seal, their composition of parts, and installation instructions.