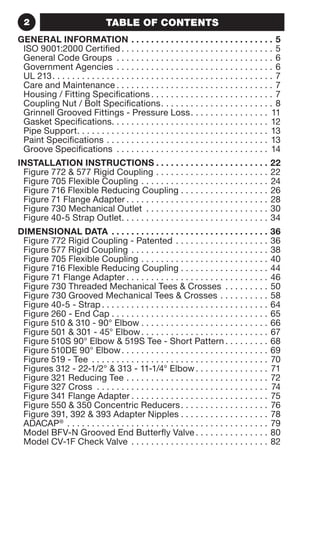

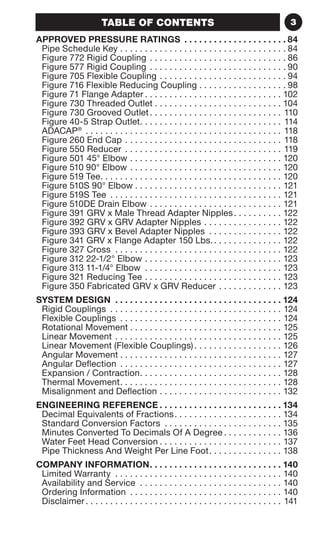

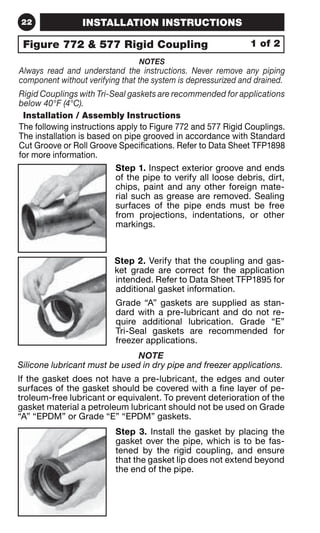

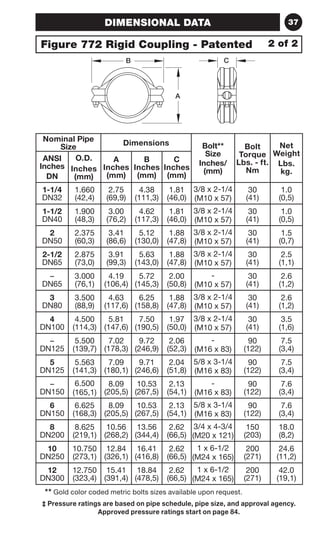

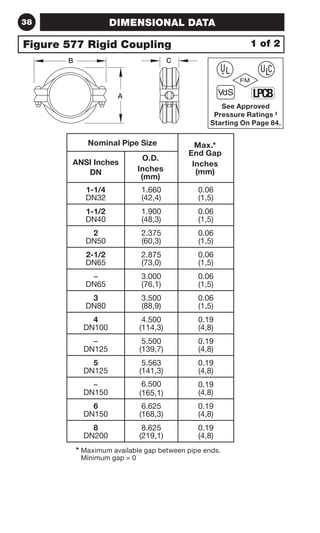

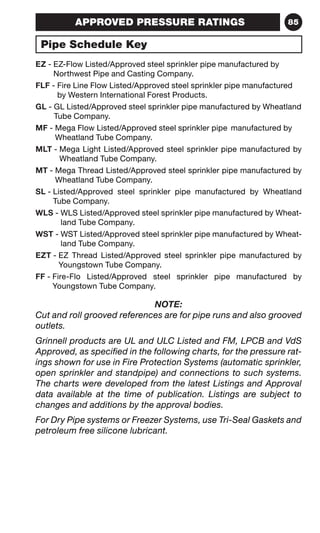

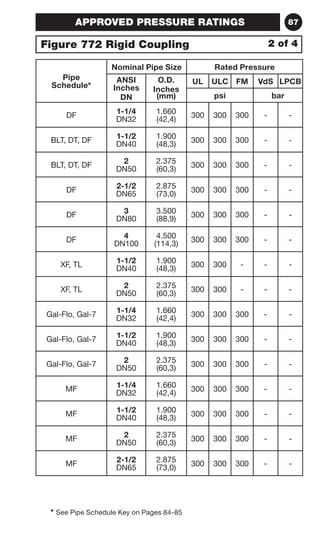

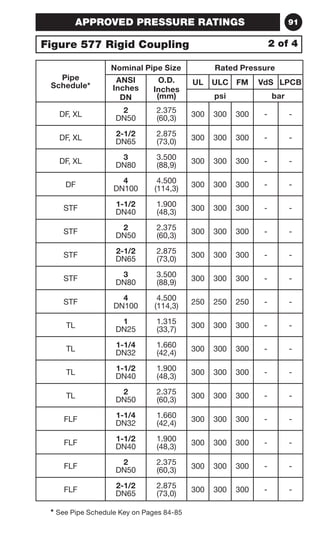

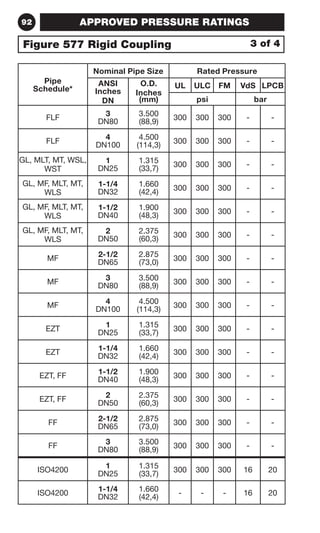

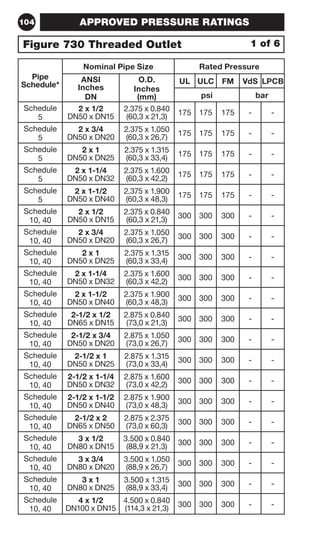

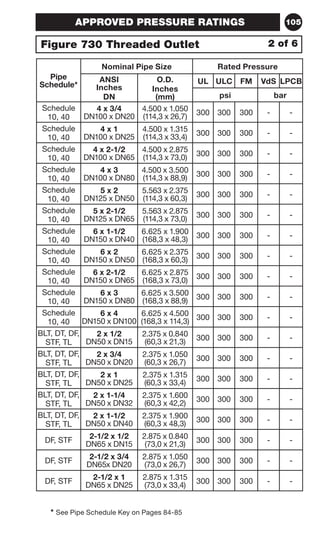

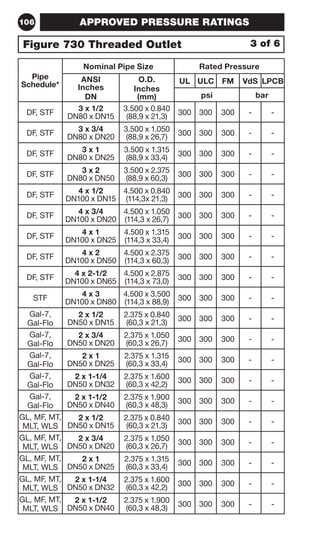

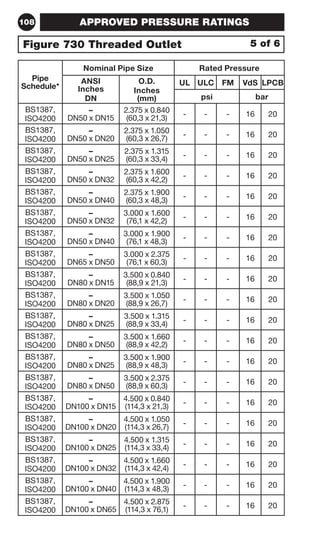

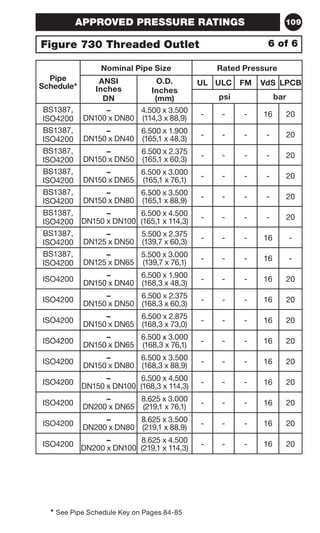

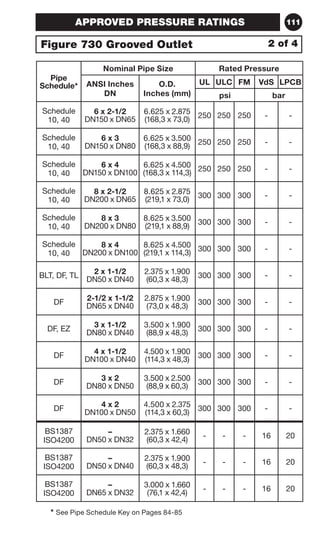

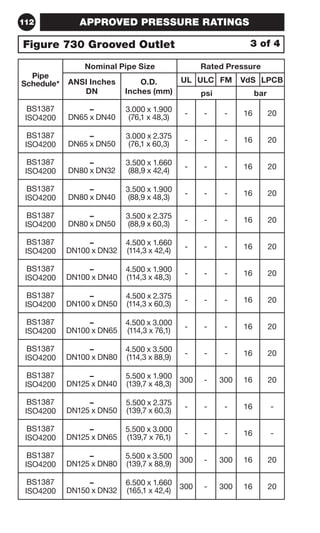

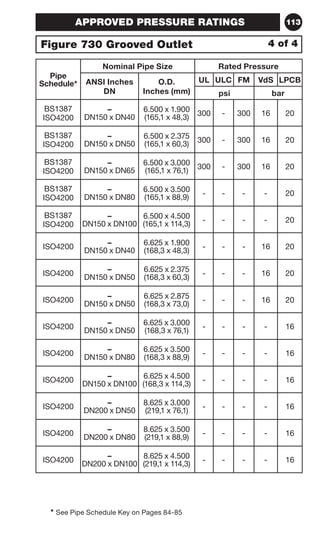

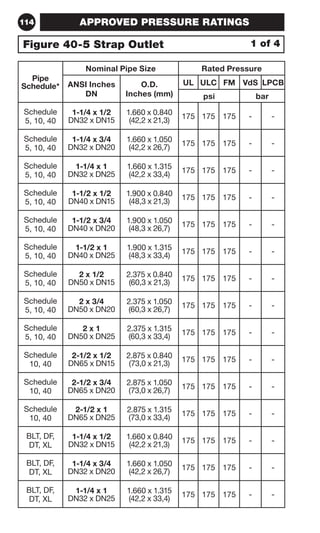

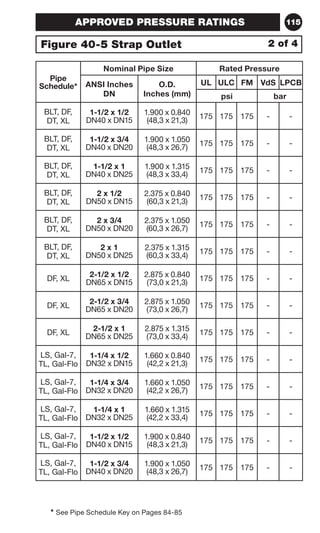

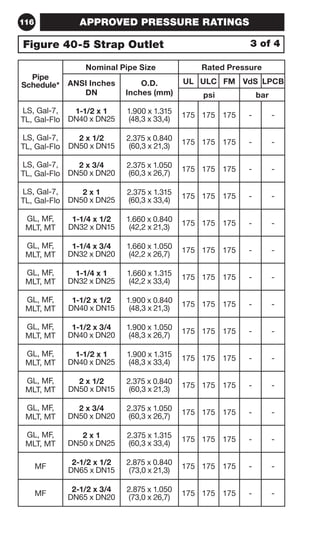

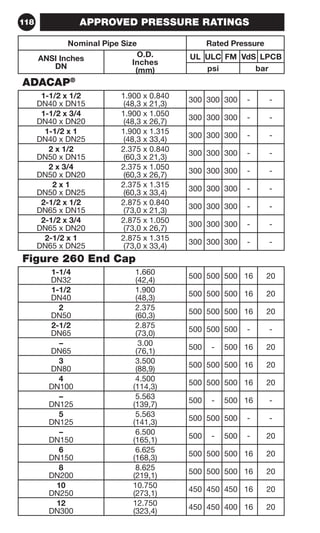

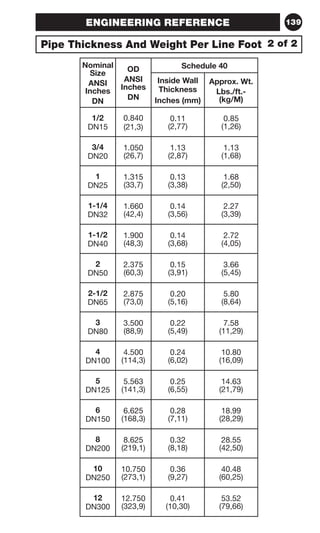

This document is an installation manual for the IH-1000FP fire protection system. It provides specifications and installation instructions for various components of the fire protection system, including couplings, fittings, outlets, valves and other parts. It includes dimensions, pressure ratings, and guidelines for properly designing, installing and maintaining the system according to codes and standards.