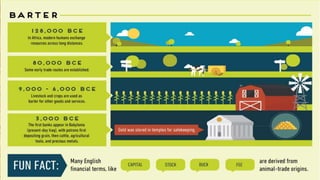

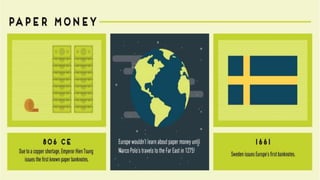

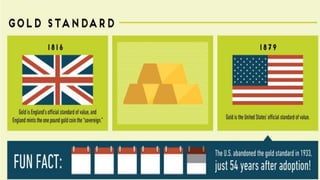

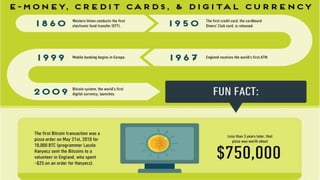

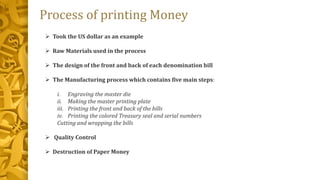

Money has a long history, evolving from bartering to commodity money to coins to paper currency. The US dollar printing process involves engraving master dies, making printing plates, and using intaglio printing on specialized paper with security features. Bills go through quality control before destruction of unusable notes. Modern money is fiat currency not backed by precious metals, though it was representative money tied to gold or silver values in the past. Understanding the history and production process provides context around modern monetary systems.