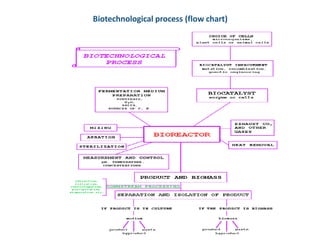

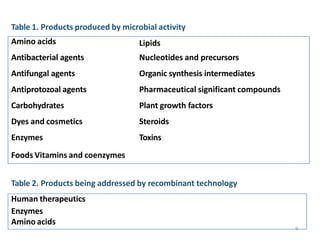

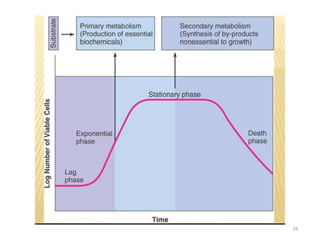

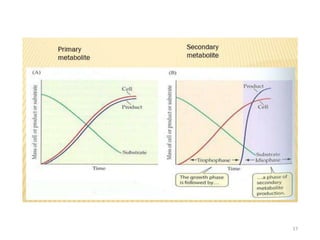

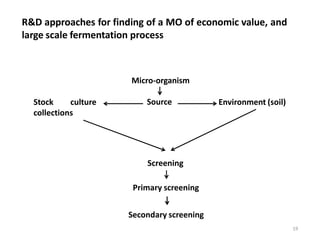

This document provides an overview of bioprocess technology and fermentation. It discusses that bioprocessing uses living cells or their components to produce desired products, often through fermentation. The document outlines the key stages of bioprocessing including upstream processing, fermentation, and downstream processing. It also distinguishes between primary and secondary metabolites, with primary metabolites directly involved in growth and secondary metabolites having other functions like protection. The document provides examples of products from fermentation and how bioconversions can be used to transform substrates.