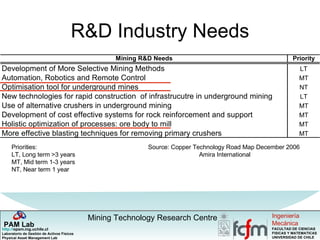

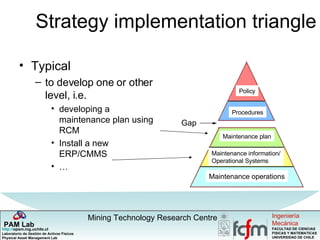

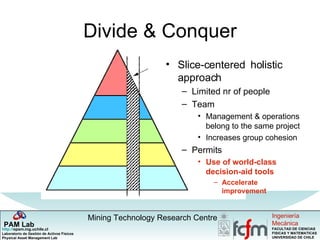

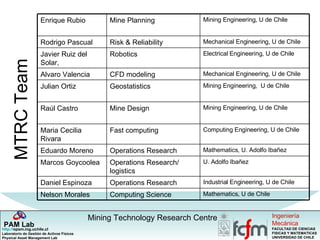

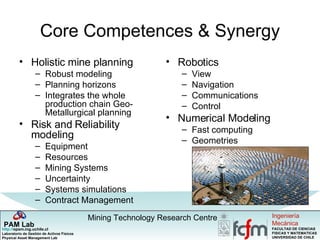

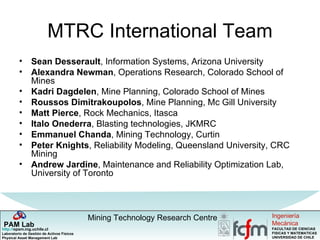

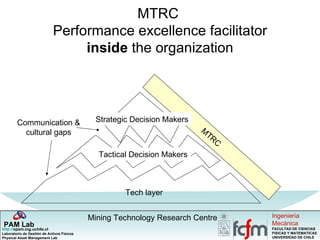

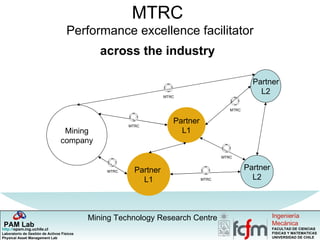

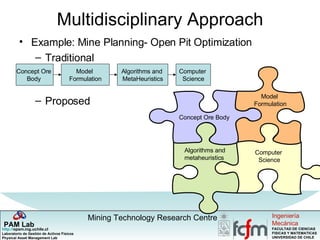

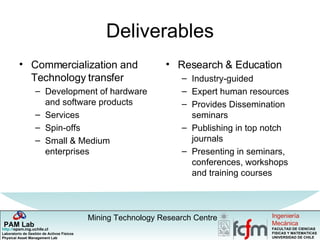

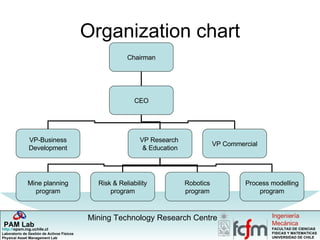

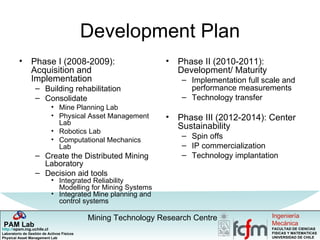

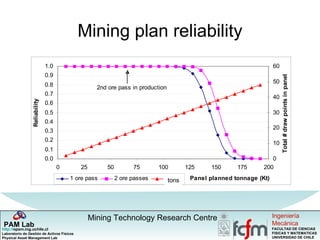

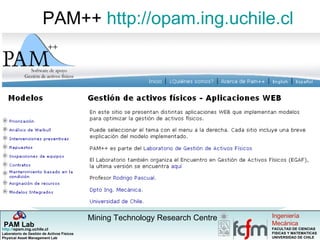

The document proposes the creation of the Mining Technology Research Center (MTRC) in Chile as a collaboration between universities and the mining industry. The MTRC would conduct applied research and development to help solve challenges in mining operations, processes, safety, and sustainability. It would focus on areas like mine planning, asset management, robotics, and modeling. The goal is to establish core competencies, develop tools and technologies, train students, and transfer innovations to industry partners to boost productivity and safety in mining. A multi-phase development plan and financing model are presented to establish the MTRC as a world-leading mining research center.