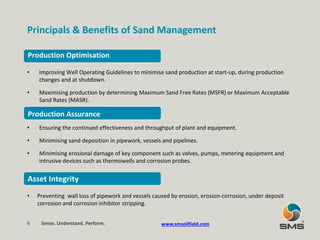

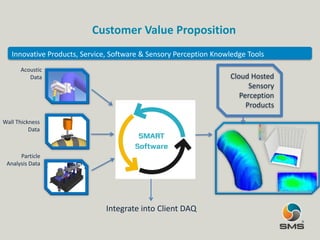

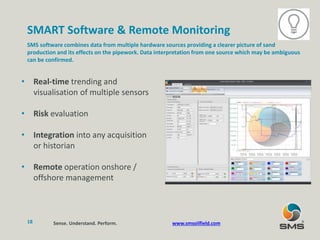

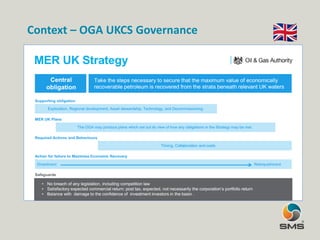

This document discusses a networking event on production chemistry. It summarizes a sand management alignment project with three key elements: introducing the industry context, explaining how sand management aligns with the Maximizing Economic Recovery strategy, and discussing development of modular sensing technologies and a software hub to provide sand visibility. The project aims to optimize production and assure asset integrity through principles of sand management like improving guidelines to minimize sand production and determining maximum sand rates.

![5

Definition of Sand Management

"The consideration of all subsurface and surface

aspects related to sand (solids) in the production

of oil & gas. [Including but not limited to:

prediction; sand control; flow assurance

(transportation/erosion); monitoring; sand

handling; and disposal.]"

Sand Management Network 2011

Sand Management](https://image.slidesharecdn.com/smsproservmarch19mersandmanagementalignment-190322140016/85/MER-and-Sand-Management-Alignment-5-320.jpg)