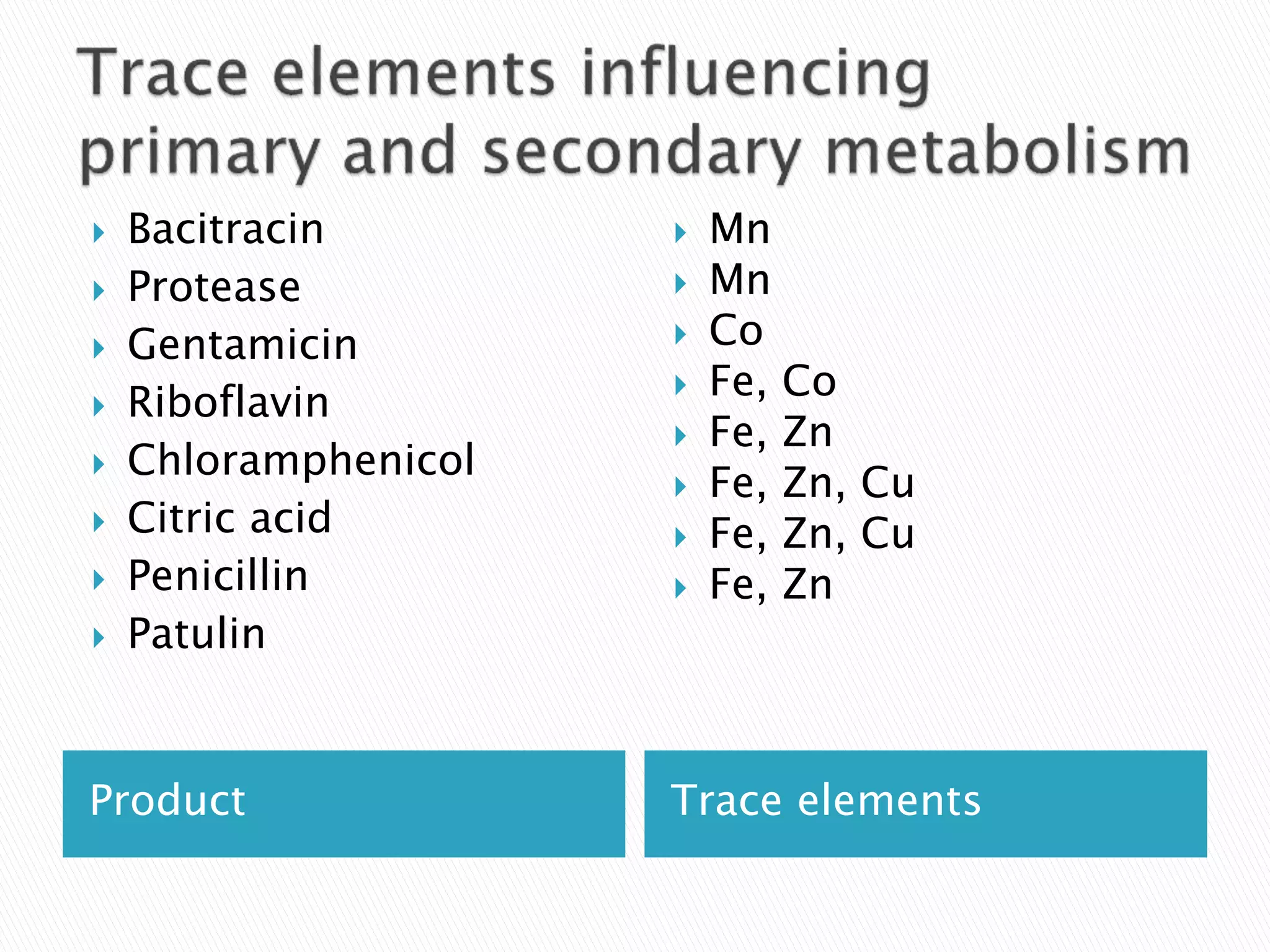

This document discusses the key components required for microbial growth and fermentation, including carbon, nitrogen, minerals, vitamins and oxygen. It outlines the goals of optimizing fermentation media to maximize product yield while minimizing undesirable byproducts. Finally, it examines various carbon sources, nitrogen sources, minerals, trace elements and antifoaming agents used in fermentation media formulation.