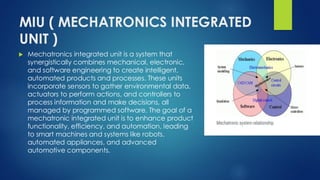

Mechatronics integrated unit is a system that

synergistically combines mechanical, electronic,

and software engineering to create intelligent,

automated products and processes. These units

incorporate sensors to gather environmental data,

actuators to perform actions, and controllers to

process information and make decisions, all

managed by programmed software. The goal of a

mechatronic integrated unit is to enhance product

functionality, efficiency, and automation, leading

to smart machines and systems like robots,

automated appliances, and advanced

automotive components.