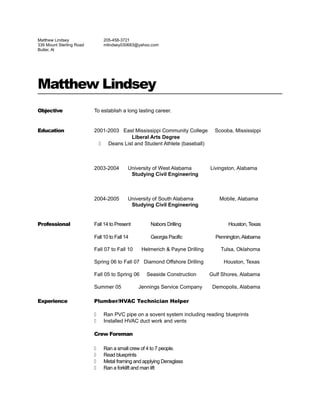

Matthew Lindsey is seeking a career in engineering and has experience in various roles in construction, drilling, and manufacturing industries. He has a liberal arts degree from East Mississippi Community College and studied civil engineering at two universities. His experience includes roles as a roustabout, deck coordinator, motorman, converting technician, floorhand, and helper in areas like HVAC, metal framing, and power plant operations. He provides references from current and former supervisors.