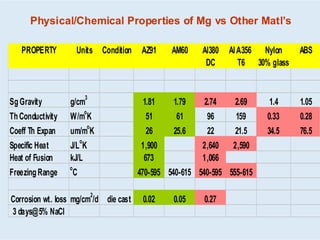

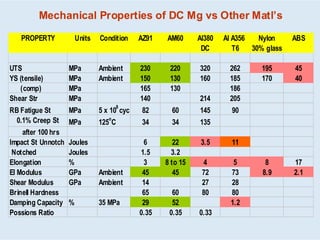

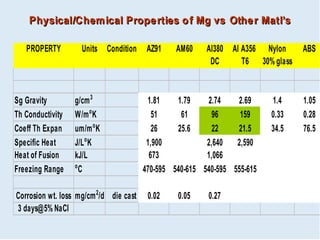

This document summarizes and compares the physical, chemical, and mechanical properties of magnesium alloys AZ91 and AM60 to other common materials like aluminum alloys and plastics. Some key points are:

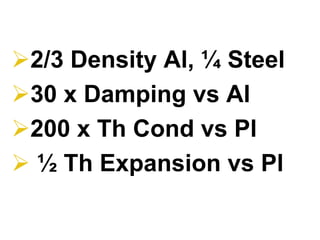

- Magnesium alloys have a density about two-thirds that of aluminum but higher than plastics. They also have much higher thermal conductivity and damping capacity.

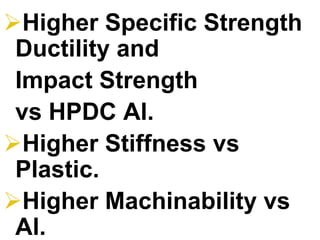

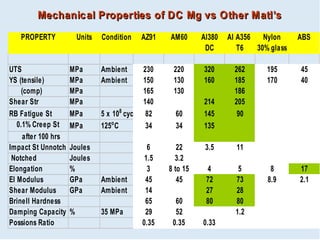

- Mechanically, magnesium alloys have higher strength-to-weight ratios than aluminum or plastics. They also have good ductility, impact strength, and fatigue strength.

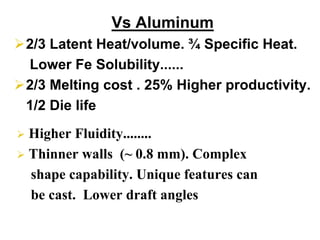

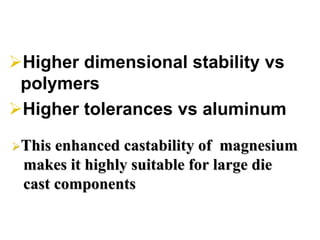

- Processing of magnesium alloys provides advantages over aluminum like lower melting costs, higher productivity in die casting, and ability to form complex shapes with thin walls, making magnesium