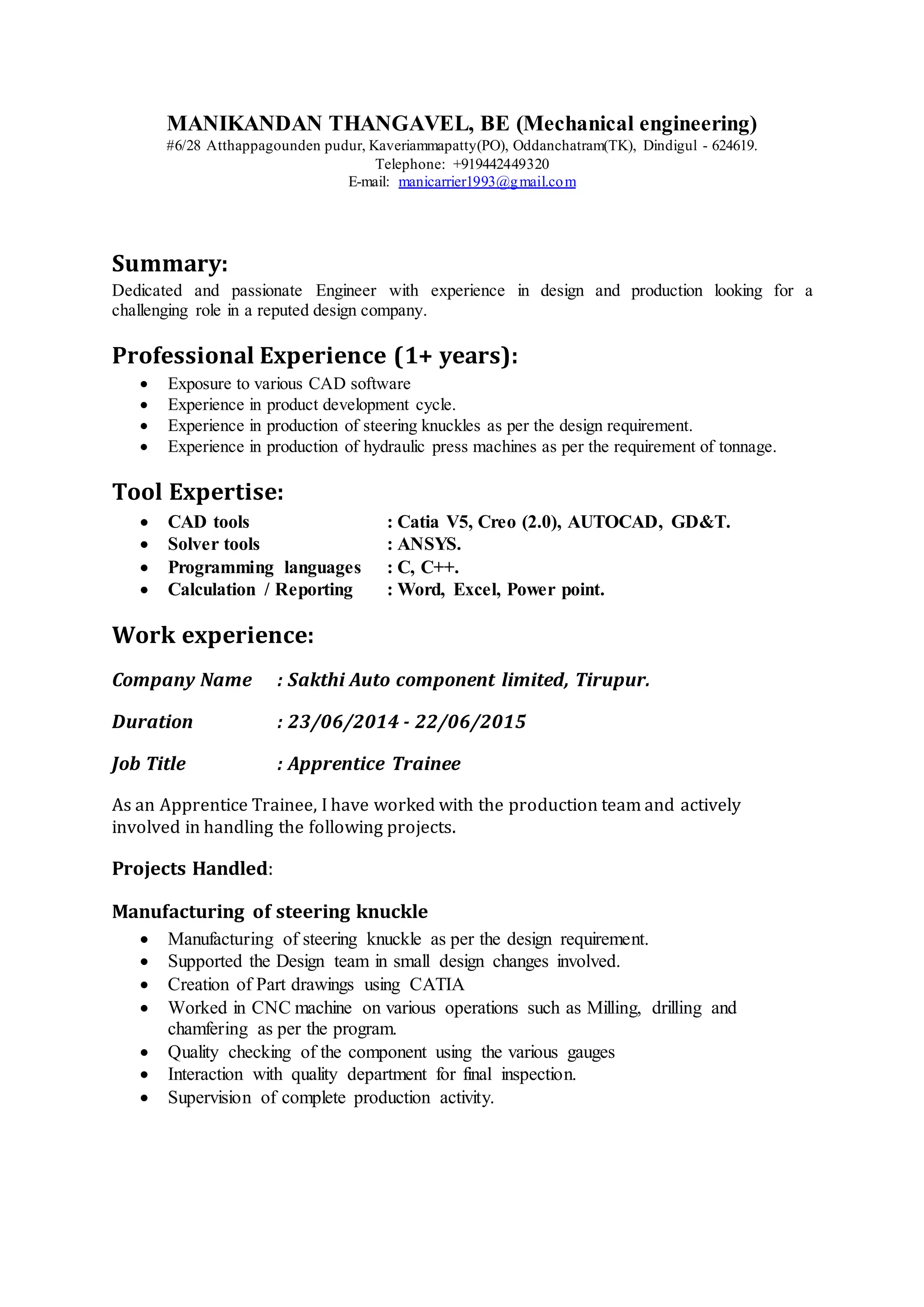

Manikandan Thangavel is a mechanical engineer seeking a challenging role in design. He has 1+ years of experience in CAD, product development, and production of parts like steering knuckles and hydraulic presses. He is proficient in CAD tools like Catia and Creo, as well as simulation tools like ANSYS. He has worked as an apprentice and production engineer for companies in Tirupur and Bangalore, where he was involved in projects for manufacturing steering components, hydraulic presses, and stamping machines.