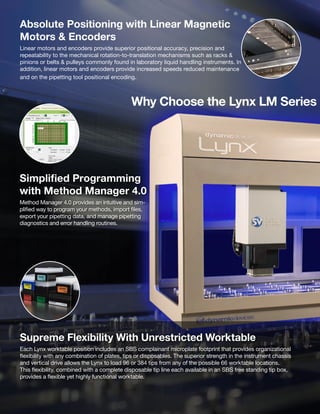

The document describes several liquid handling robotic platforms from the Lynx LM series that can be configured for laboratory automation needs. Key features of the platforms include configurable pipetting tools that offer 96-channel and 8-channel pipetting with volume-verified pipetting. The platforms also include standard 96-channel and 384-channel syringe pipetting tools, as well as gripping tools, vision systems, and barcode scanning capabilities. The document provides specifications for the different models and pipetting tools.