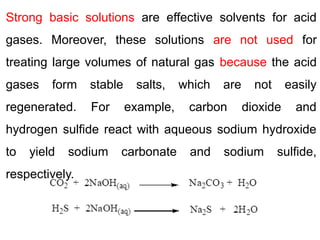

The document discusses various petroleum products and their properties, including sulfur compounds, LPG, crude oil, and natural gas. It details methods for treating natural gas to remove impurities such as acid gases and moisture to enhance efficiency and reduce corrosion. Key treatments include physical and chemical absorption processes, moisture removal methods, and the use of molecular sieves.