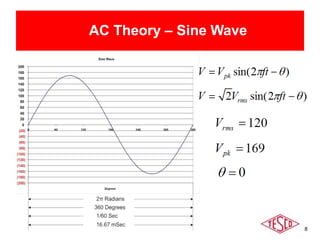

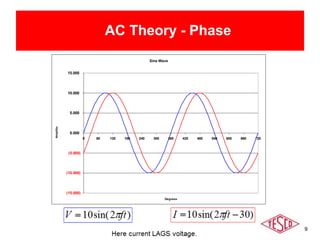

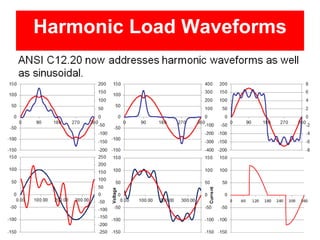

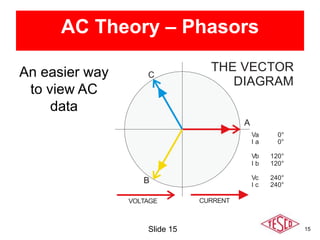

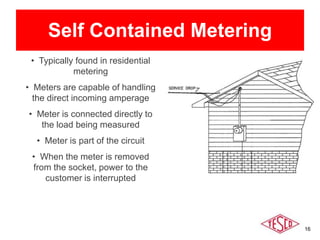

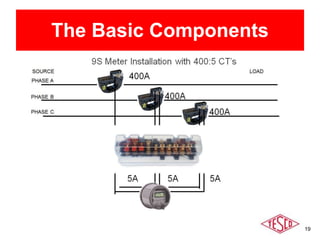

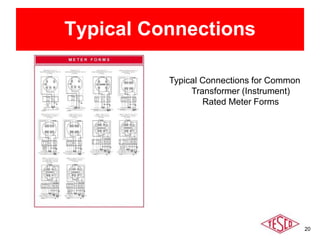

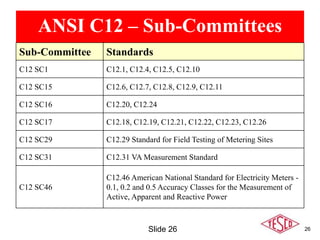

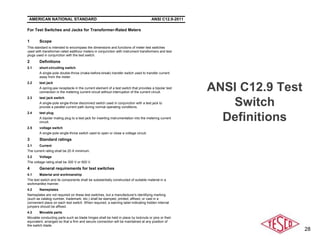

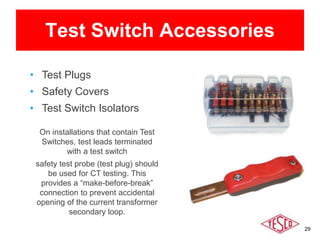

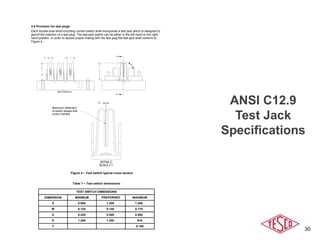

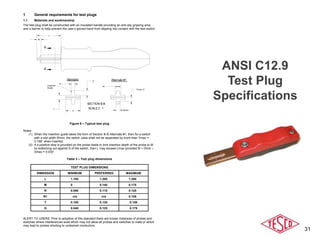

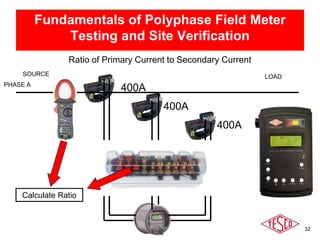

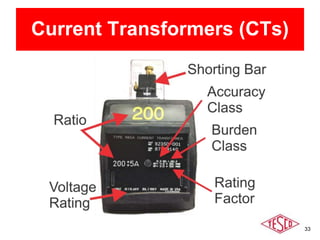

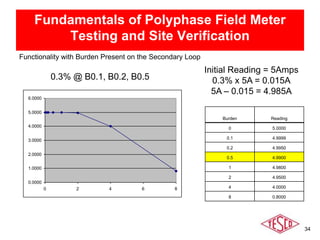

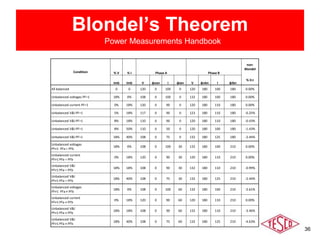

This document provides an overview of meter testing concepts and standards. It begins with an introduction to the goals of the meter school presentation. It then outlines the topics that will be covered over three days, including basic electricity, wiring diagrams, AC circuits, and different types of metering. The document provides explanations and examples of key electrical concepts such as direct current, alternating current, sine waves, phasors, and power. It also discusses meter testing standards including ANSI C12, test switch specifications, and the use of current transformers. Blondel's theorem for polyphase power is also summarized.