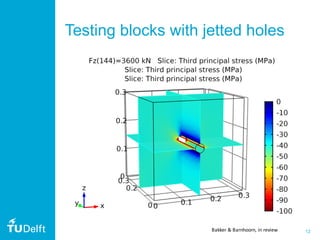

This document summarizes a laboratory study on radial jet drilling of laterals for geothermal applications. The study aims to determine if there is damage around a jetted borehole and how jet drilling performs under stressed rock conditions. Computed tomography scans and tests on jetted rock samples show little damage around the borehole for the tested rock type. Further true-triaxial jetting tests are planned with higher nozzle pressures, various stress orientations and magnitudes, and different rock types to further understand the process.