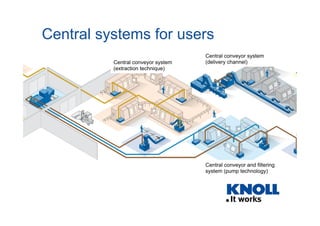

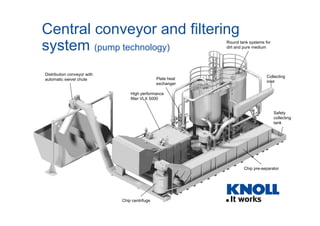

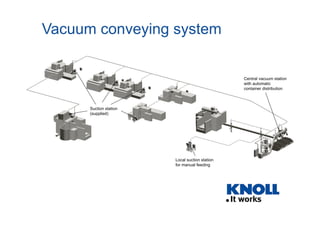

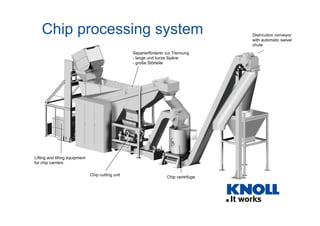

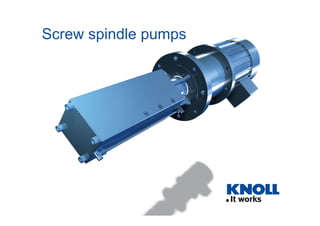

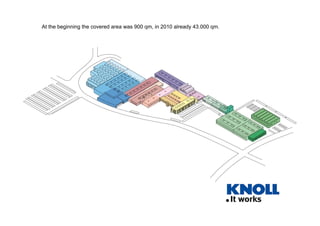

KNOLL Maschinenbau produces single units and central systems for chip conveyance and filtration for machine tools. Their customers include major machine tool manufacturers. The company has grown significantly over time and now employs around 670 people across sales, development, production, and service. KNOLL prioritizes training and currently has roughly one trainee for every nine employees. They offer 24/7 service and support for their products.