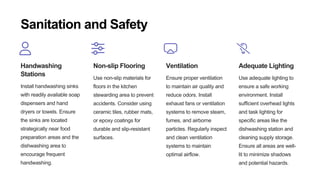

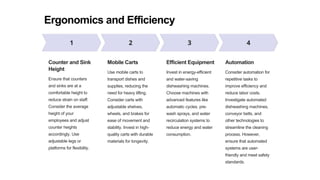

This guide outlines essential considerations for designing an efficient and hygienic kitchen stewarding layout, focusing on space planning, workflow zoning, and accessibility. Key areas include dishwashing, drying, storage, and waste management, emphasizing the importance of proper equipment and sanitation practices. The document also highlights ergonomics and the potential for automation to improve efficiency and reduce labor costs.