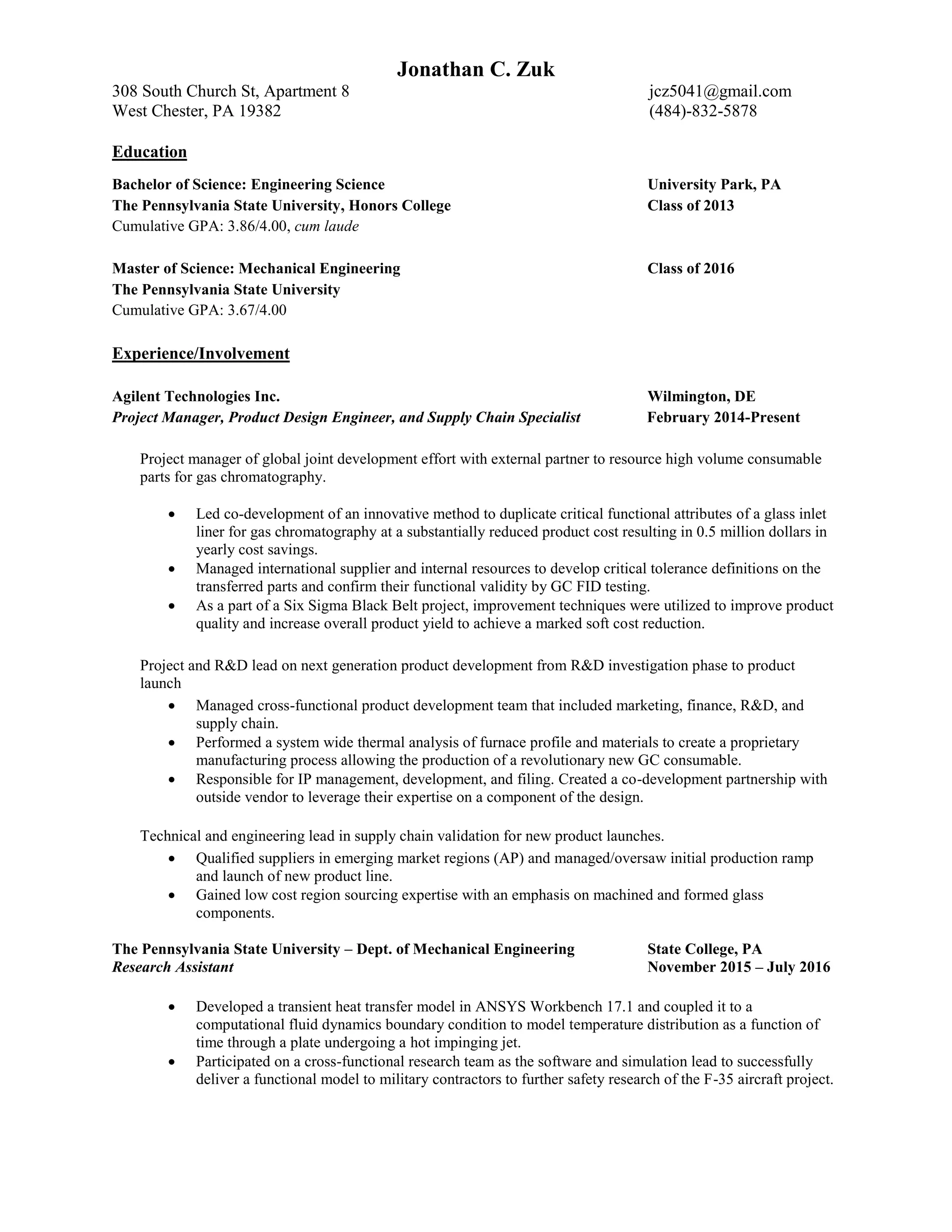

Jonathan C. Zuk has extensive experience in mechanical engineering and project management. He received his Bachelor's degree in Engineering Science from Penn State in 2013 and his Master's in Mechanical Engineering from Penn State in 2016. Currently, he works as a Project Manager, Product Design Engineer, and Supply Chain Specialist at Agilent Technologies, where he has led projects that reduced costs and improved quality and yield.