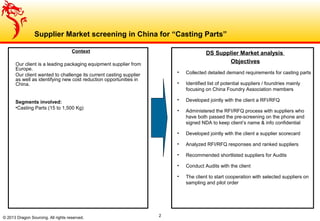

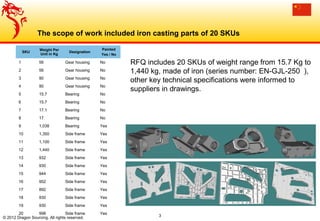

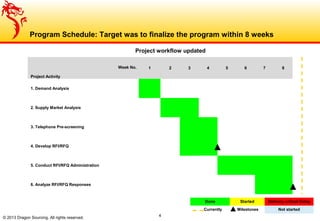

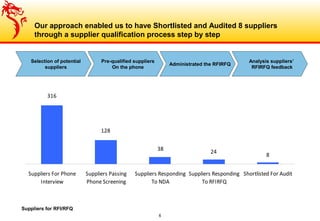

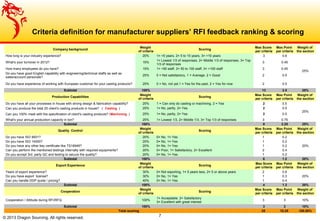

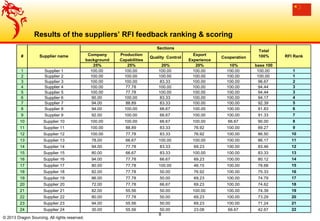

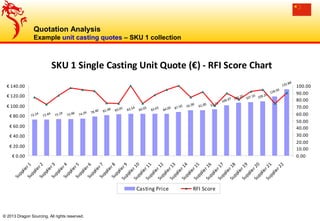

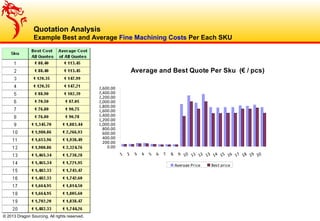

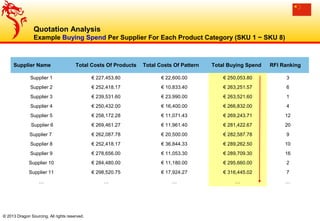

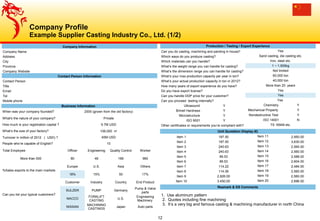

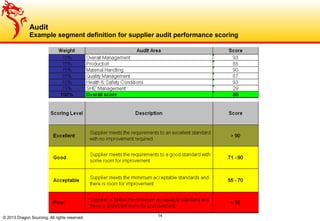

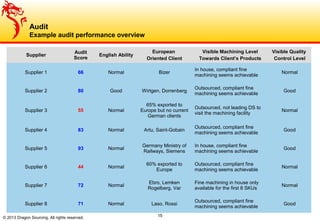

The document outlines a case study of a European packaging equipment supplier seeking to source iron cast and machined components from China to reduce costs. It details a structured supplier screening and qualification process, including demand analysis, RFI/RFQ development, audit recommendations, and a supplier scorecard. Ultimately, the client aimed to shortlist suppliers for pilot orders based on comprehensive evaluations of supplier capabilities and costs.