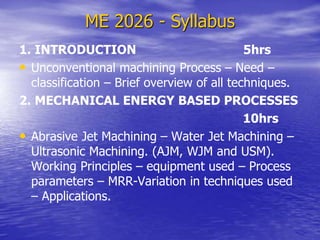

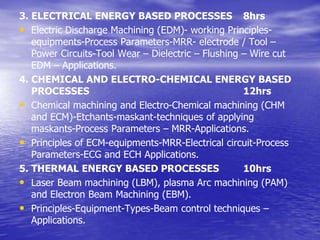

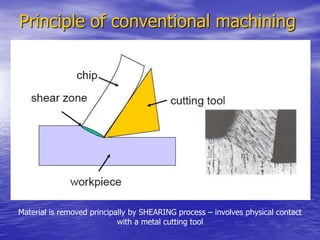

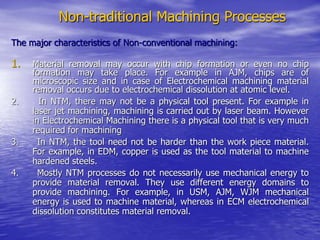

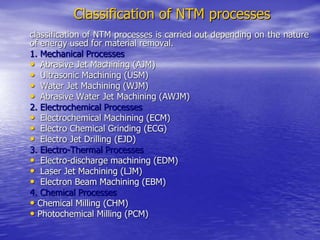

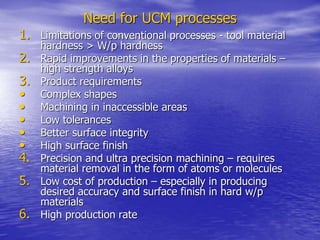

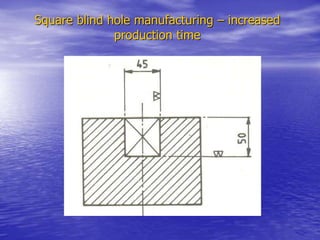

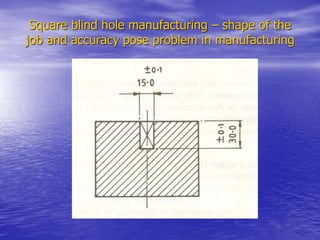

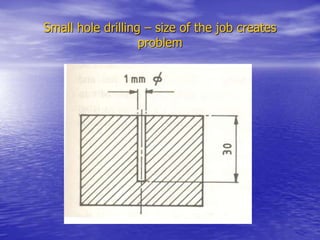

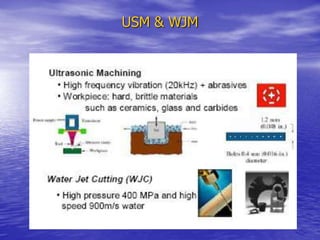

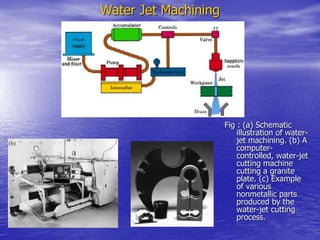

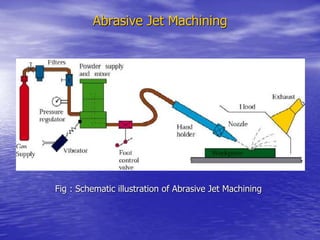

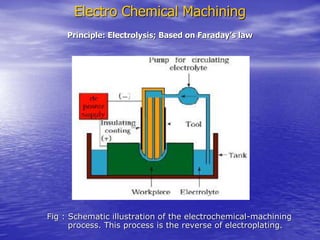

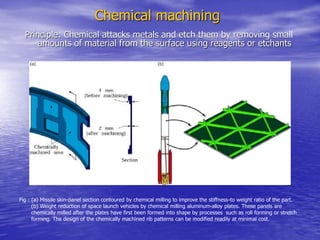

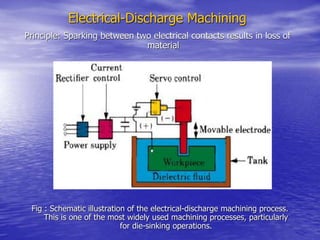

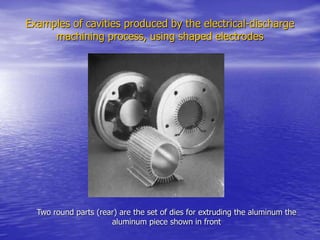

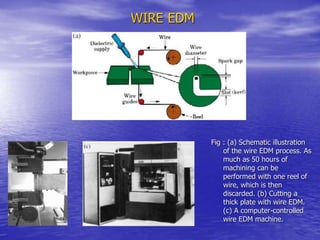

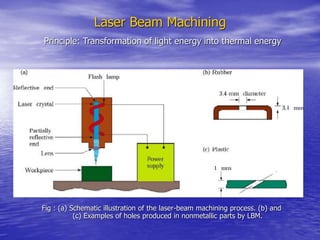

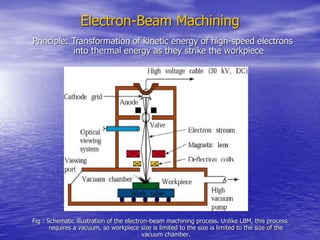

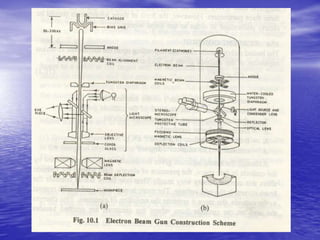

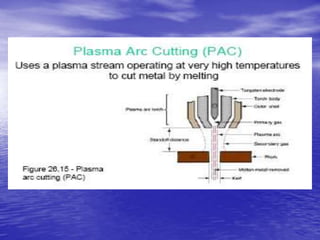

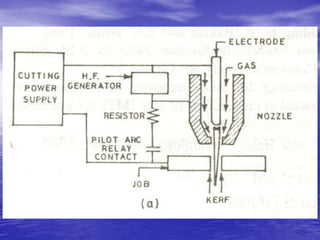

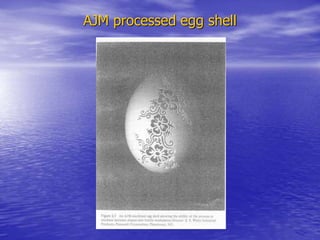

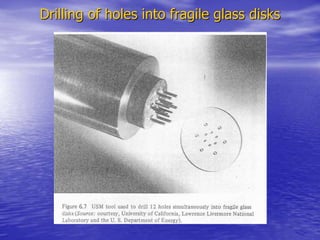

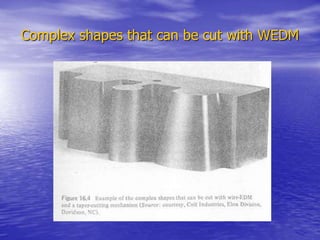

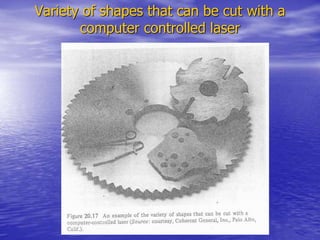

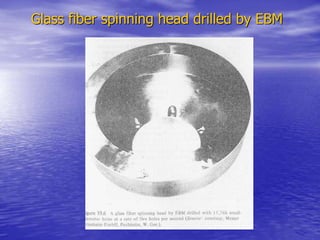

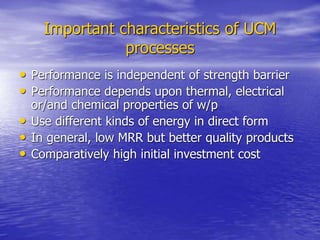

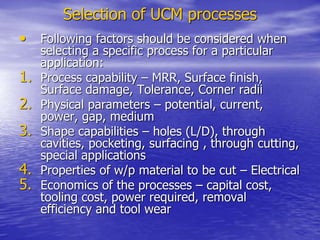

This document provides an overview of advanced machining processes, also known as unconventional or non-traditional machining. It begins with an introduction and outlines the course objectives to understand these processes and their advantages over conventional techniques. These processes are classified based on the type of energy used, including mechanical, electrical, chemical/electro-chemical, and thermal. Examples of specific processes are described within each category, such as abrasive jet machining, electrical discharge machining, electrochemical machining, and laser beam machining. Diagrams are provided to illustrate key principles and applications for several of the machining methods.