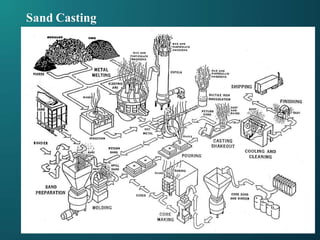

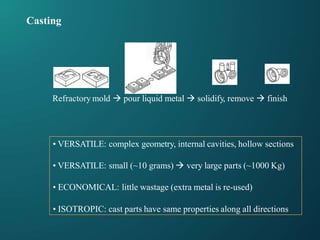

1. Sand casting is a versatile and economical process that uses refractory molds to produce metal parts. It can produce parts ranging in size from small to very large.

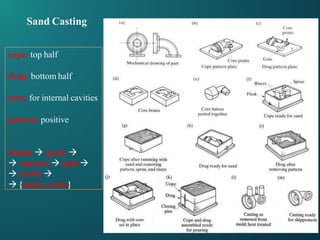

2. Sand casting molds are made by packing sand around a pattern to form cavities and then pouring molten metal. Molds are single-use and destroyed after casting is removed.

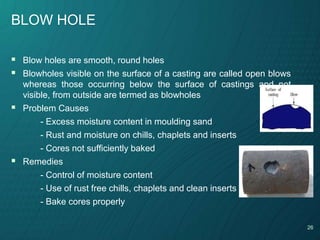

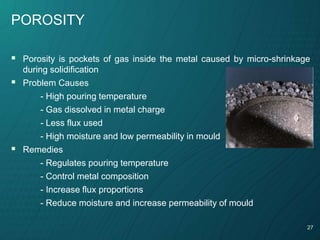

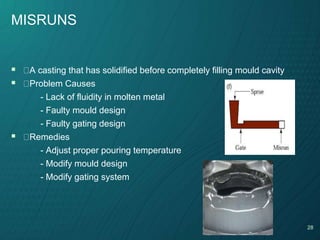

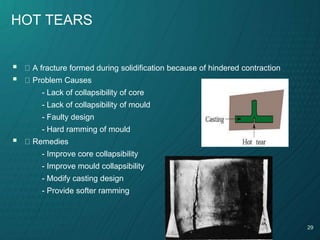

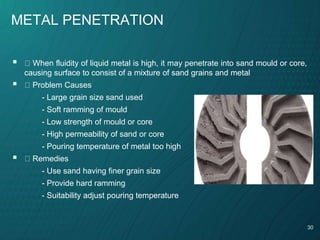

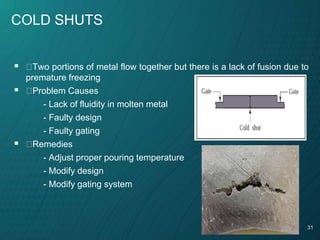

3. Common defects in sand castings include blowholes from moisture, porosity from gas entrapment, misruns from improper gating, and hot tears from constrained solidification. Careful control of the casting process can minimize defects.