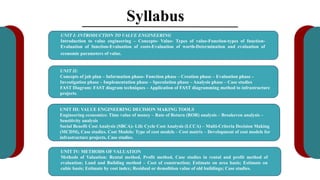

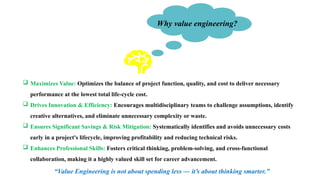

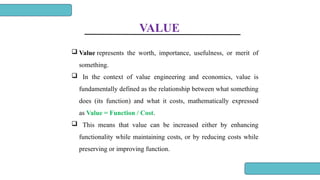

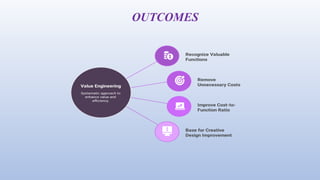

This presentation provides an overview of the background and historical development of Value Engineering (VE). It explains how Value Engineering originated as a systematic approach to improve value by optimizing function while reducing unnecessary costs. The presentation traces the evolution of VE from its early beginnings in industrial and manufacturing sectors to its widespread application in engineering, construction, and project management. It also highlights key milestones, principles, and contributors that shaped Value Engineering into an effective decision-making and cost-optimization tool used in modern projects.