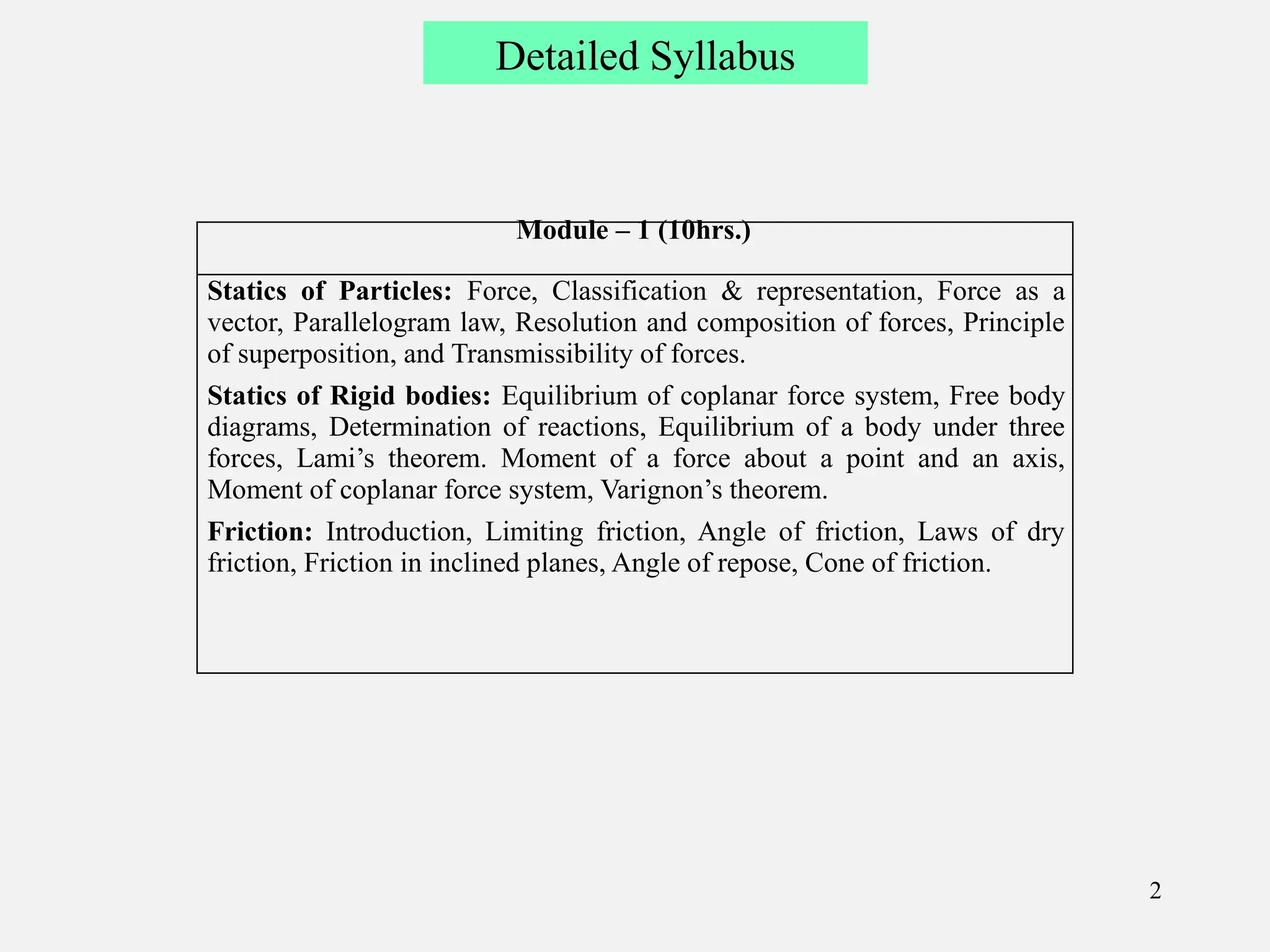

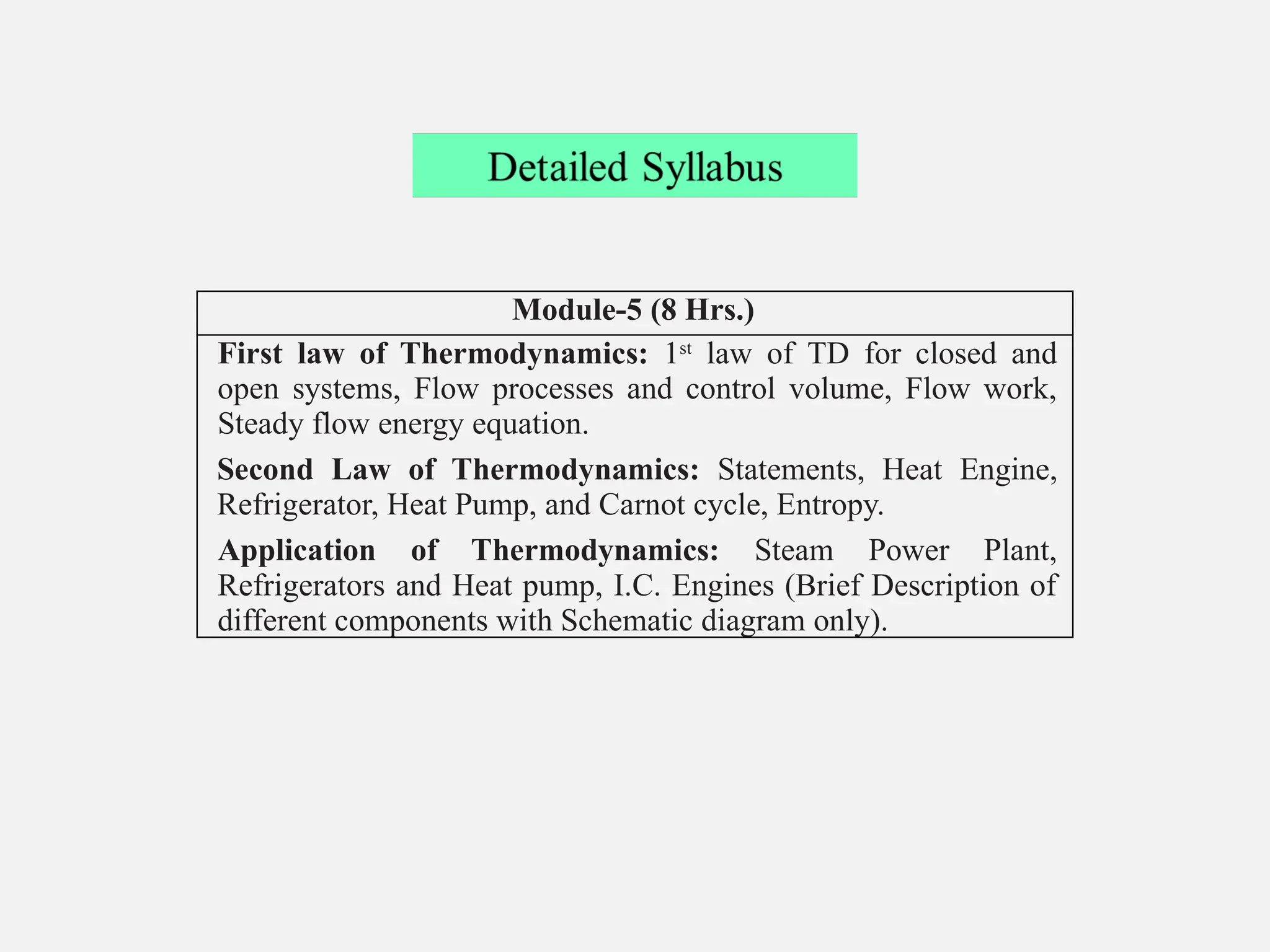

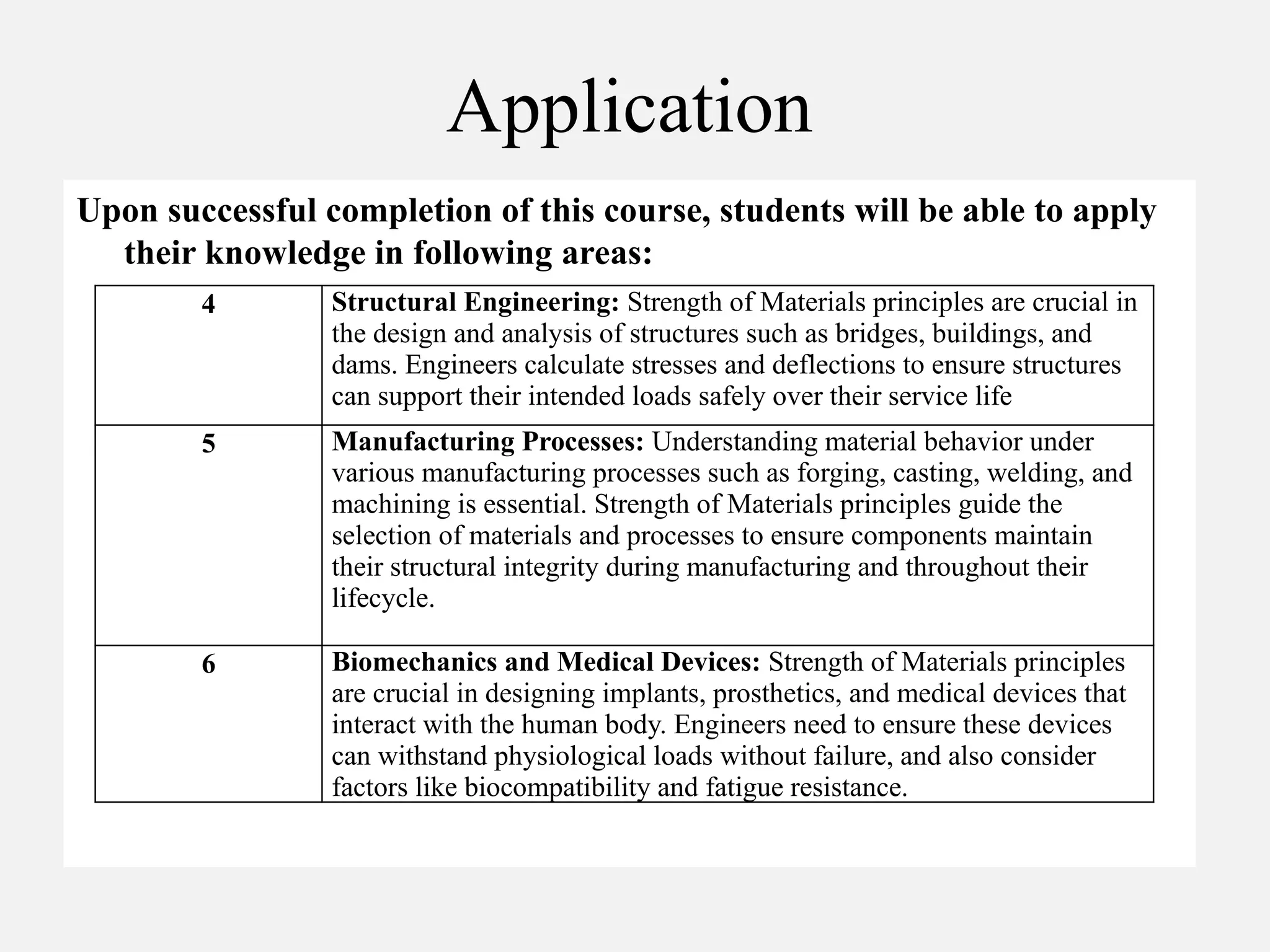

The document outlines the syllabus for an Introduction to Mechanical Engineering course, focusing on topics such as statics, thermodynamics, and structural analysis over several modules. It details the skills students are expected to acquire, including applying mechanics to static bodies, analyzing forces in trusses, and understanding the principles of thermodynamics and their applications in various engineering fields. Additionally, the document discusses evaluations and the importance of these engineering principles in real-world applications such as machine design, aerospace, and structural engineering.