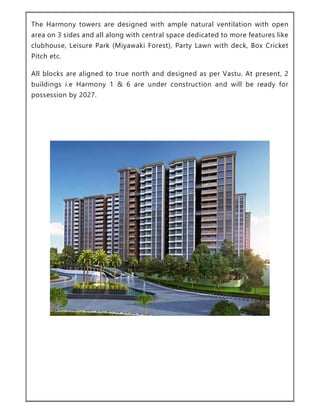

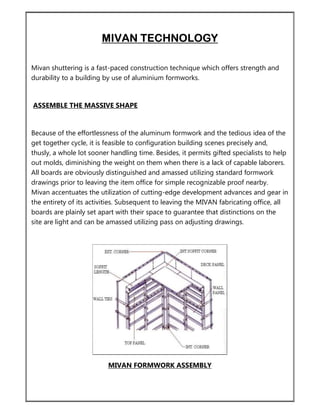

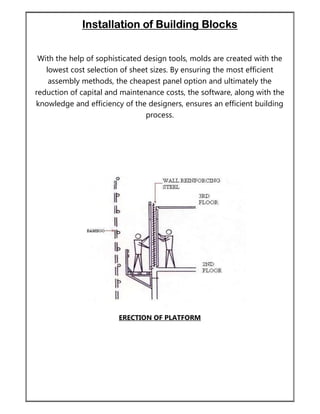

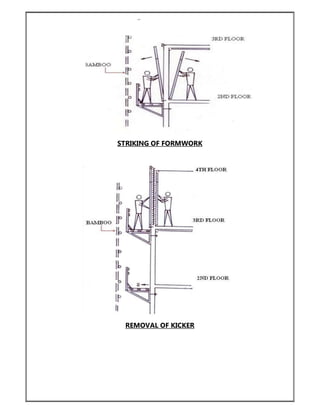

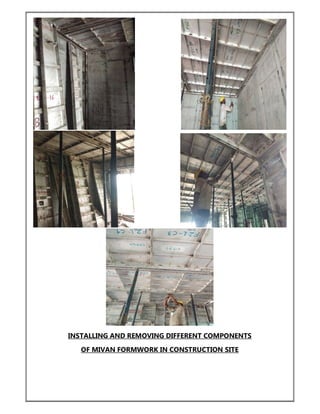

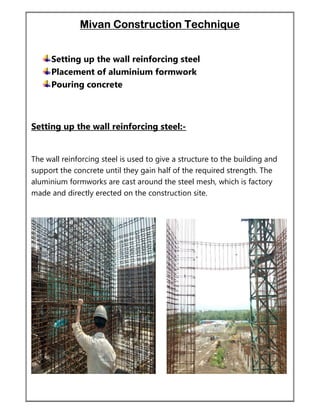

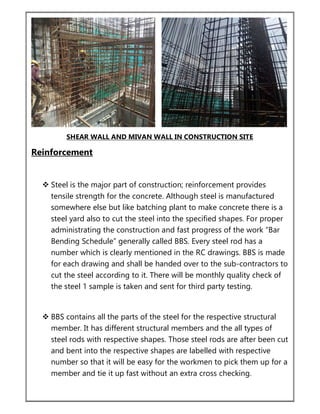

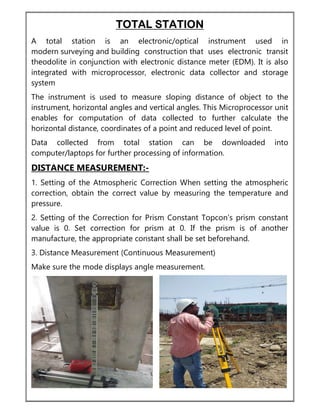

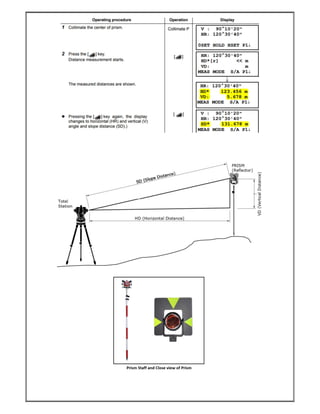

The document is an internship report submitted by Pranjal Singh Parihar, a 7th semester civil engineering student. It summarizes their 15-day internship spent observing construction of a multi-story residential building project called FCP Harmony in Nagpur, India. Over the course of the internship, the student learned about various aspects of construction including formwork setup, reinforcement, concrete mixing and placement, and curing. The report provides details on the companies overseeing construction, project specifications, tasks performed each day, and components and process of mivan formwork used for vertical surfaces.