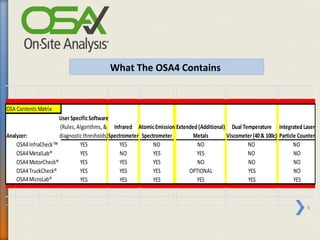

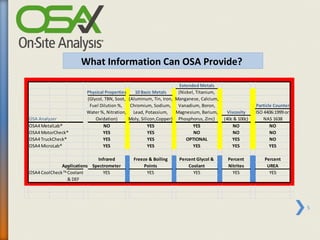

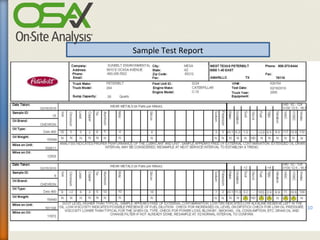

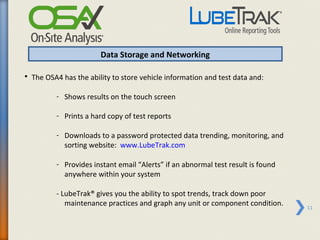

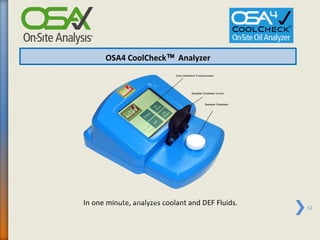

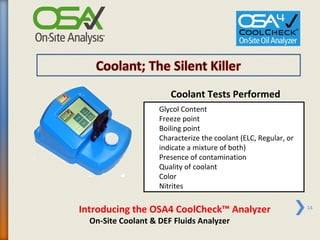

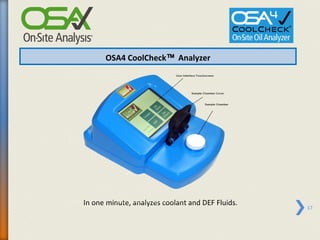

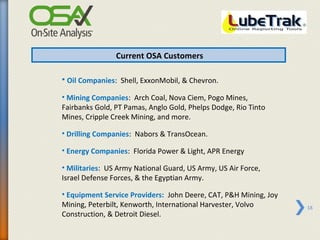

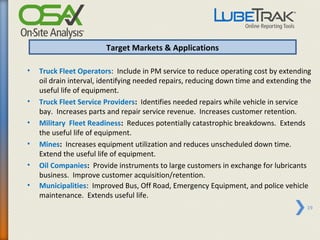

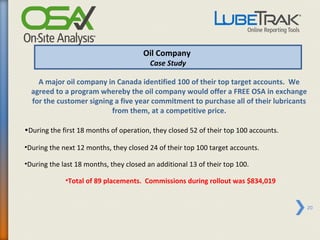

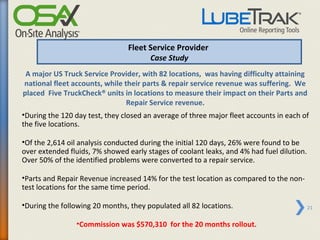

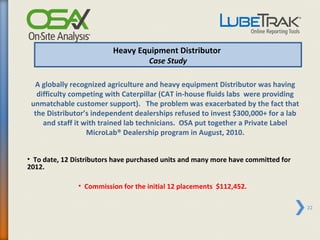

This document provides information about On-Site Analysis, Inc. (OSA), a company that manufactures on-site fluid analysis instrumentation. OSA was founded in 1986 and has headquarters in Florida and manufacturing facilities in Massachusetts. The document describes OSA's product line of analyzers that can test engine oils, transmission fluids, and other materials on-site in minutes. It also outlines how the analyzers store test data online and provide fleet maintenance benefits like reducing downtime. International customers of OSA include oil companies, mining companies, militaries, and equipment manufacturers.