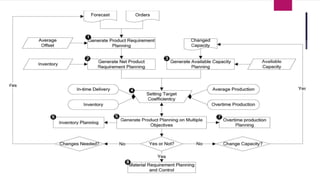

Integrated production planning aims to optimize enterprise manufacturing management by proposing a multi-objective production planning model. Current enterprise resource planning (ERP) systems are still primarily based on material requirements planning (MRP), which has shortcomings. The proposed model integrates production planning and control to achieve optimization across multiple performance objectives. ERP planning includes business, sales, operational, master production scheduling, and material/capacity planning from macro to micro levels.