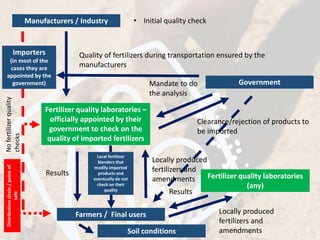

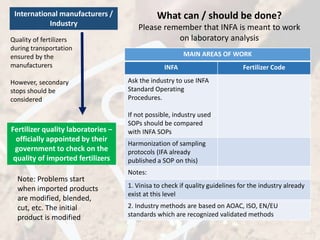

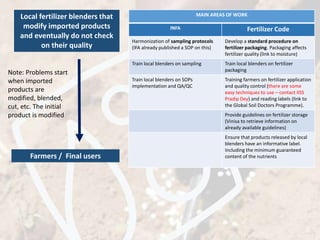

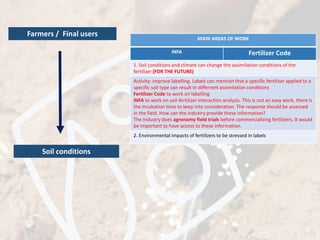

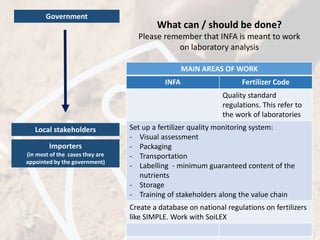

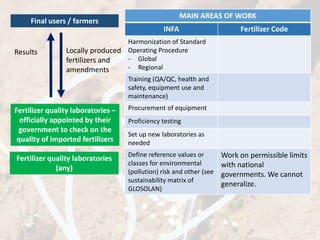

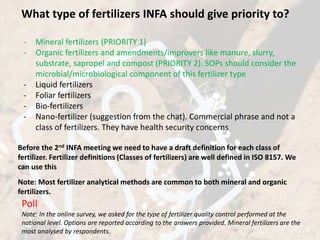

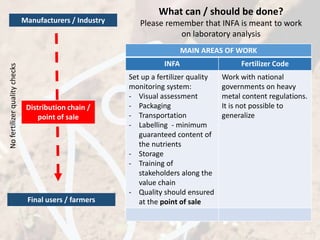

The document outlines the establishment and roles of fertilizer quality laboratories responsible for checking imported fertilizers and ensuring quality during transportation and local production. It emphasizes the need for harmonization of standard operating procedures and training for local blenders on sampling, packaging, and quality control. Additionally, it highlights the importance of informed labeling, environmental impact considerations, and the development of a monitoring system for fertilizer quality throughout the distribution chain.