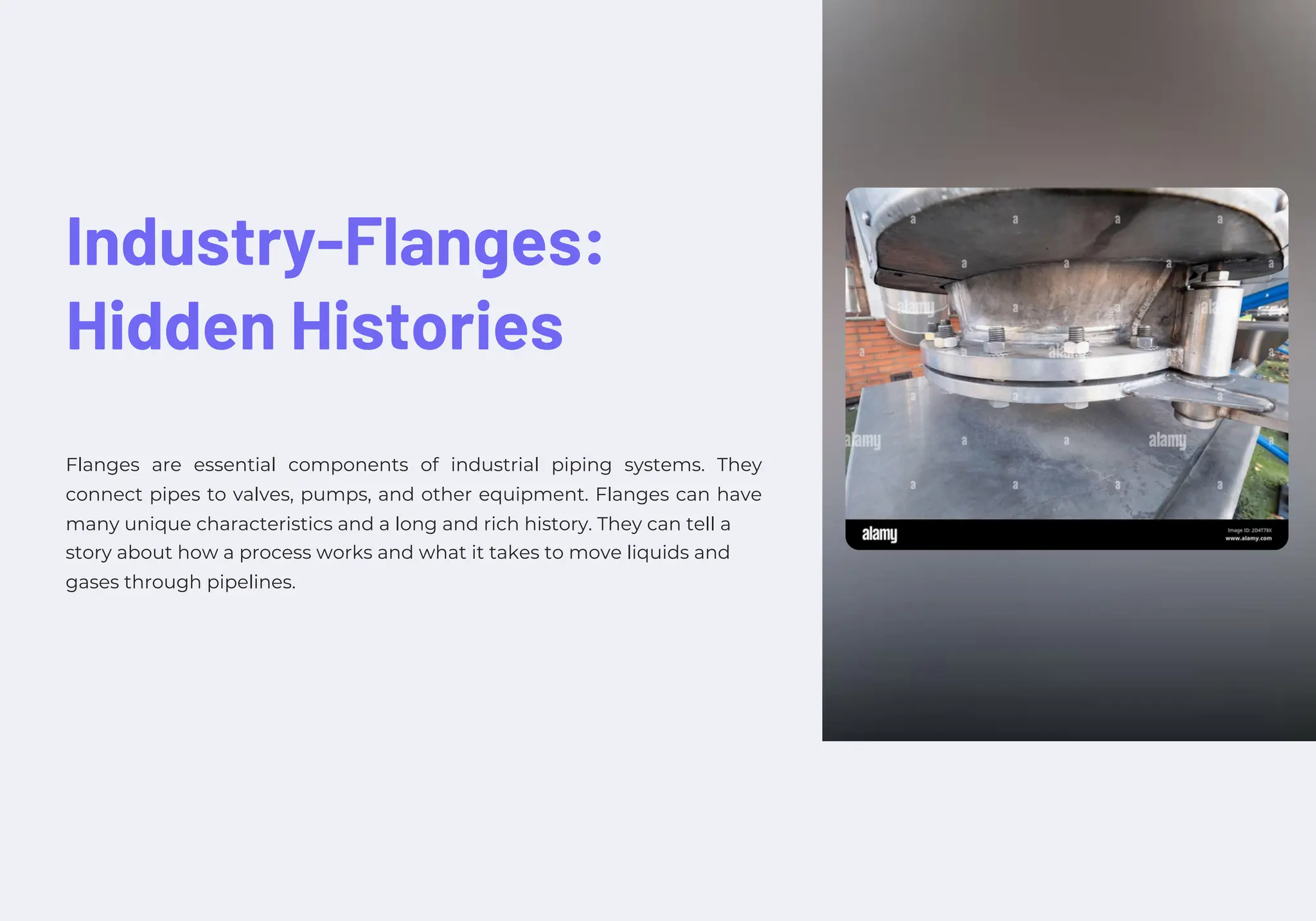

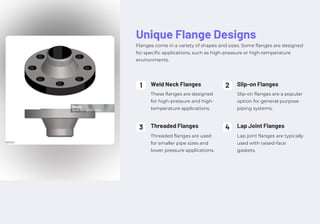

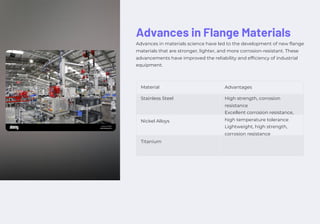

Flanges are critical components of industrial piping systems used to connect pipes to equipment, with a rich history dating back to steam engines. The document discusses the development and evolution of flange materials, standards for compatibility and safety, and various types of flanges designed for specific applications. It also highlights the importance of preventing flange failures due to corrosion and improper installation, while predicting a future trend towards sustainability and automation in flange manufacturing.