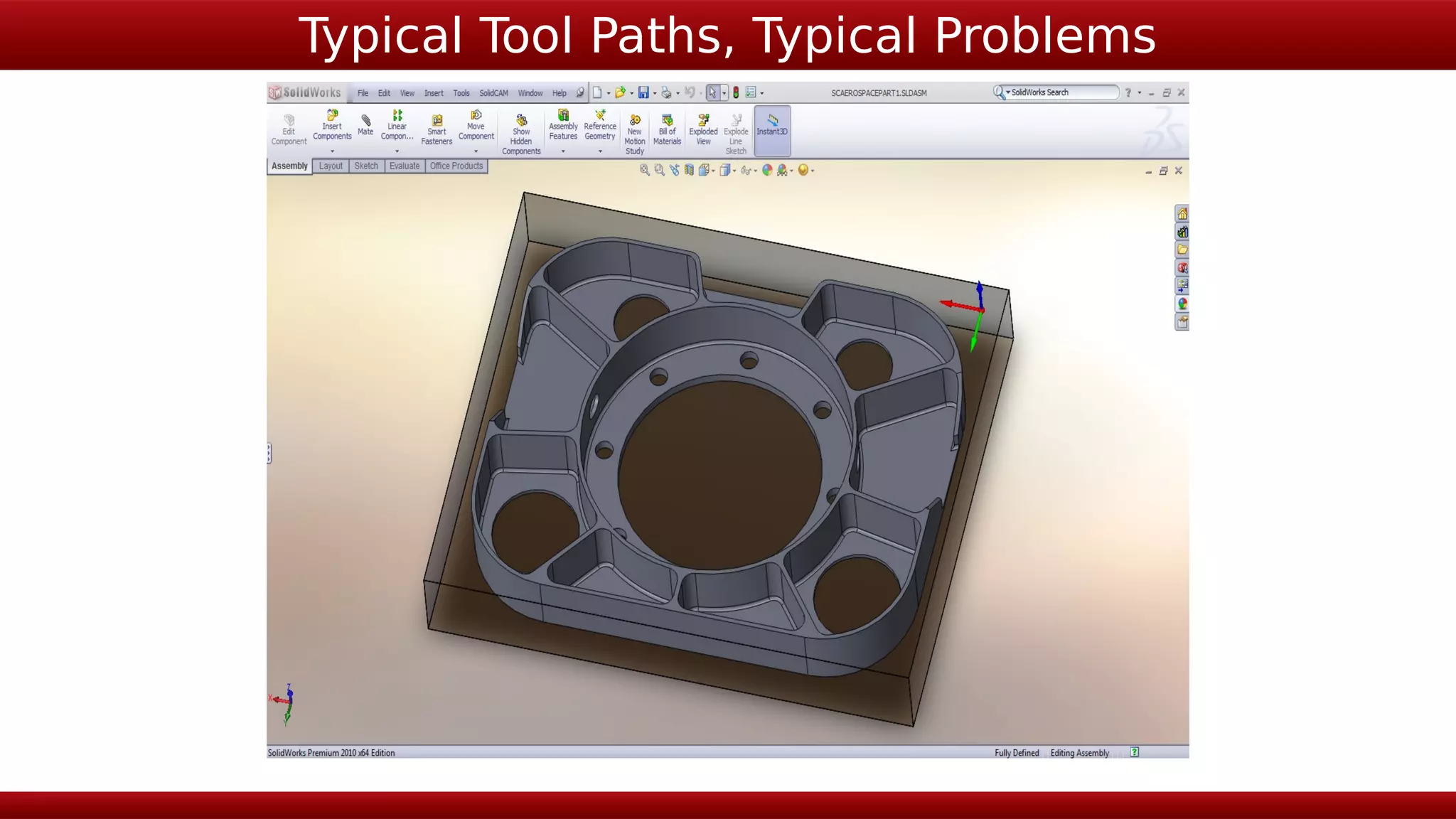

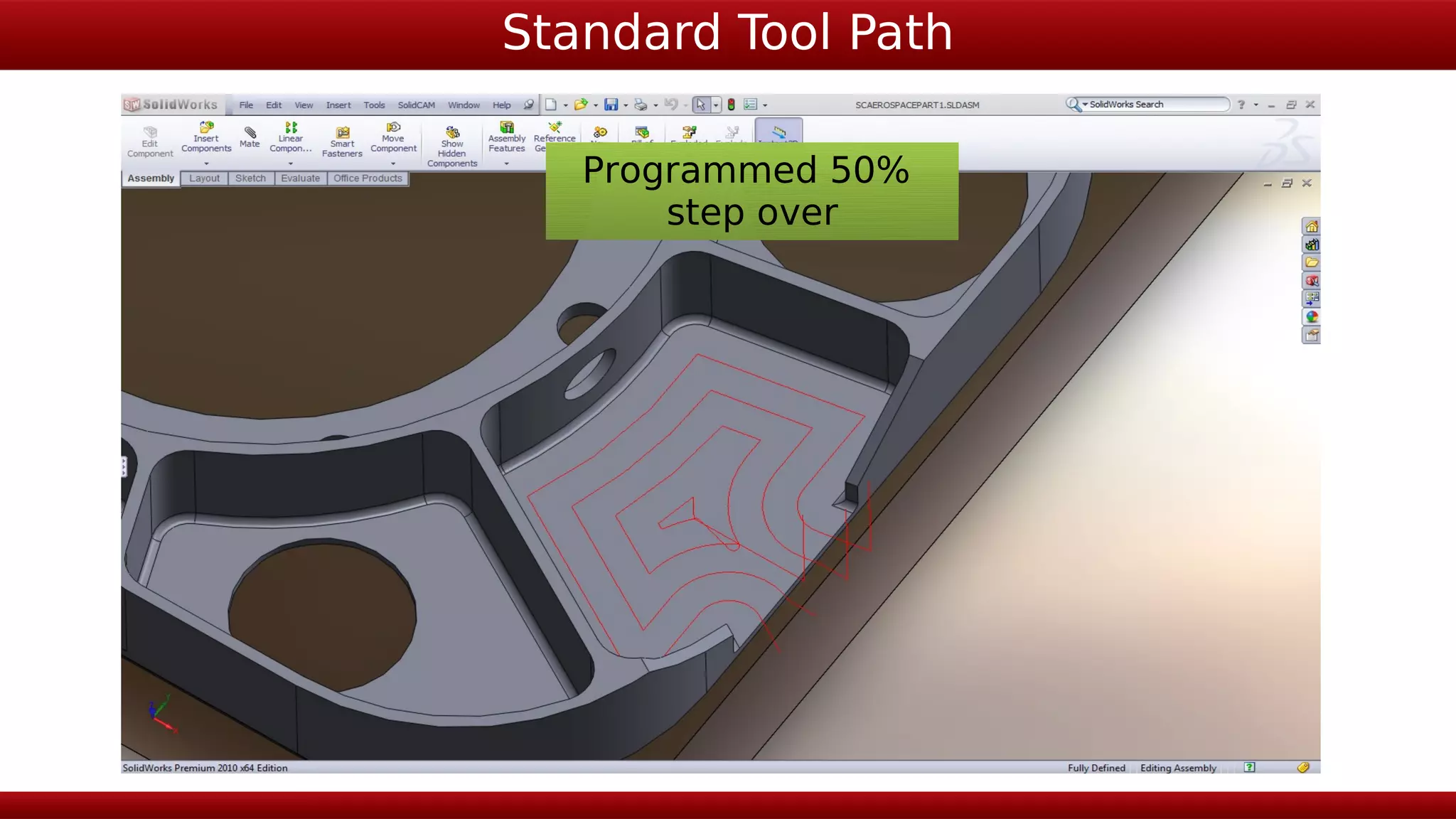

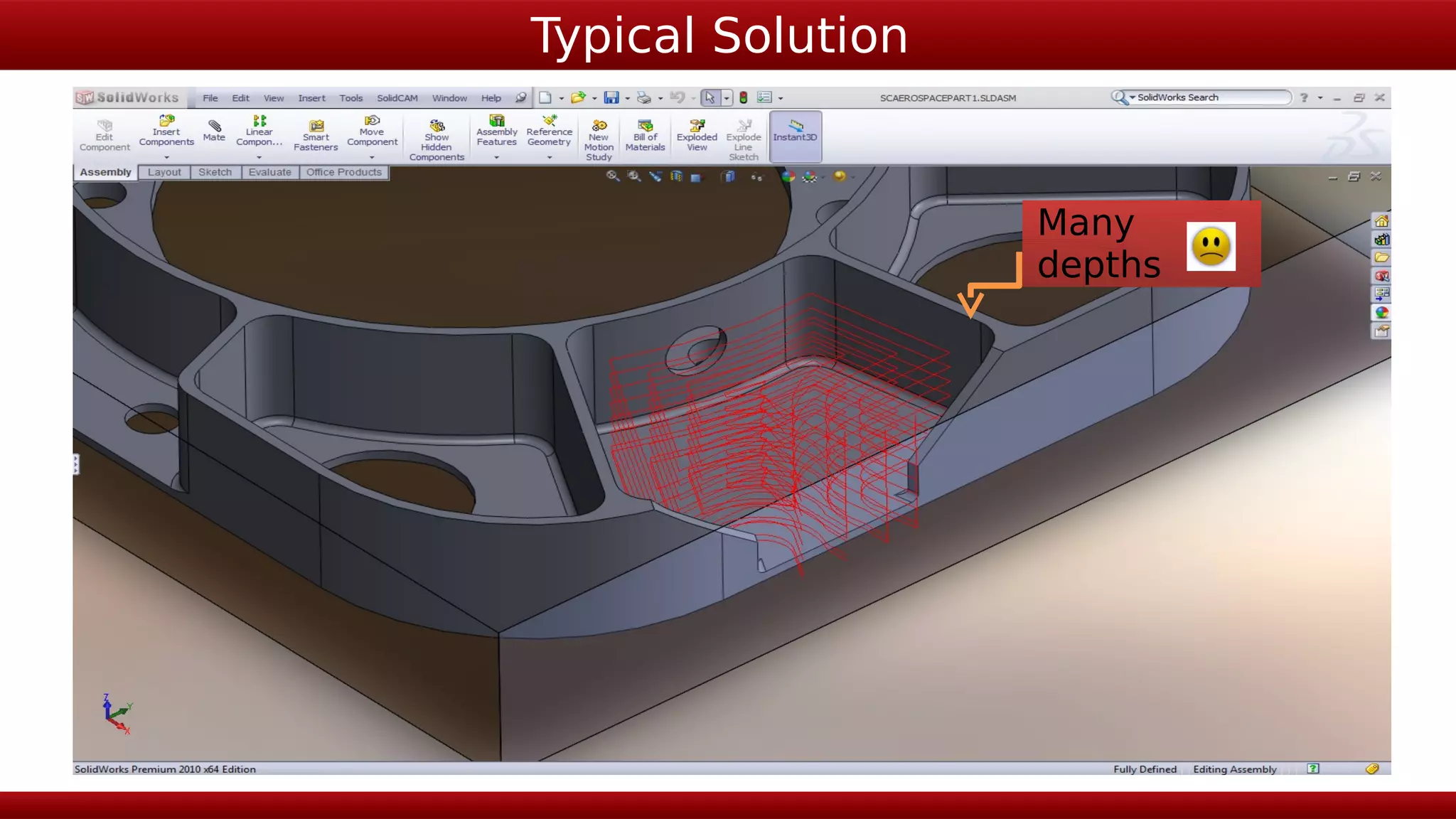

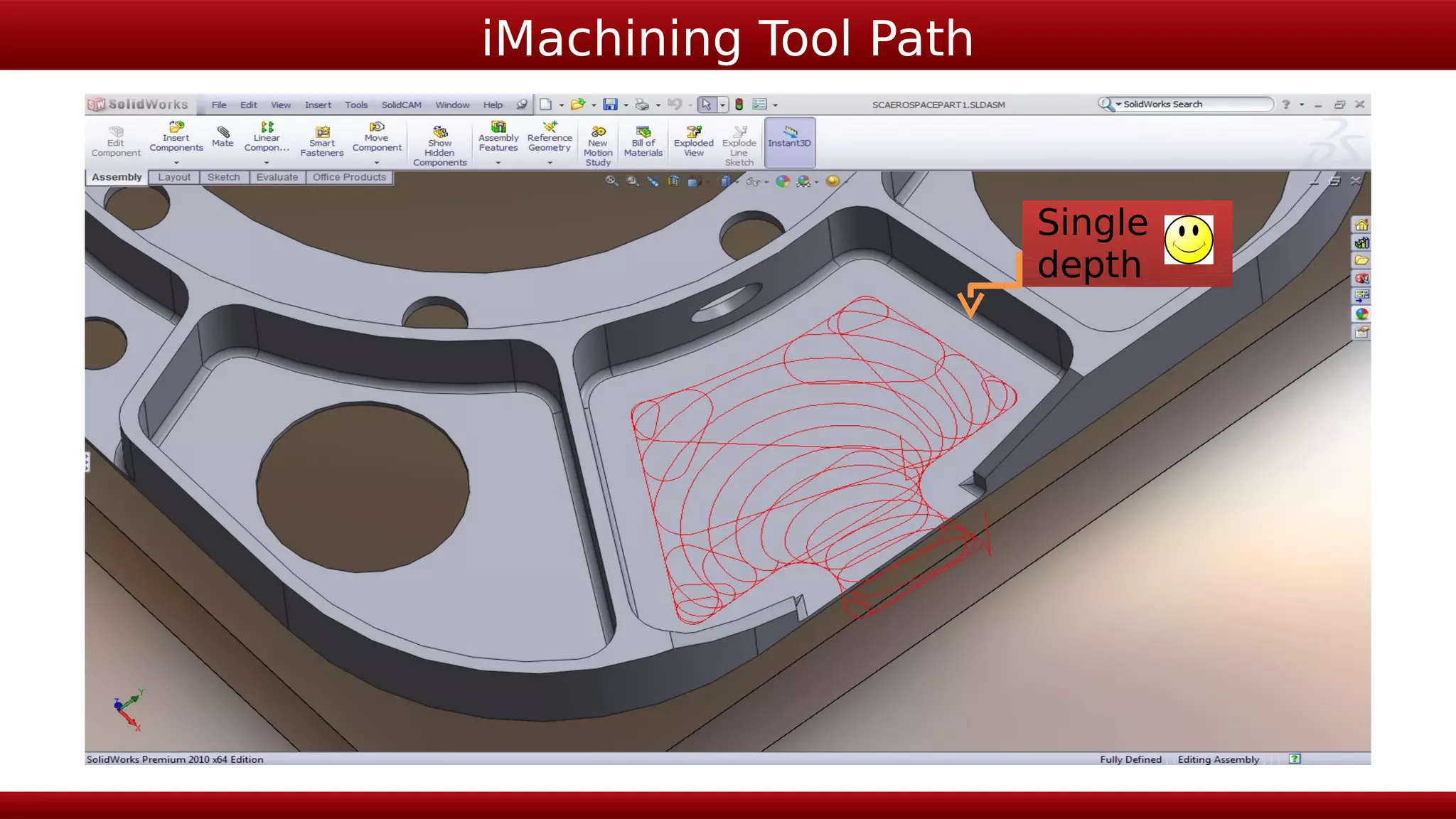

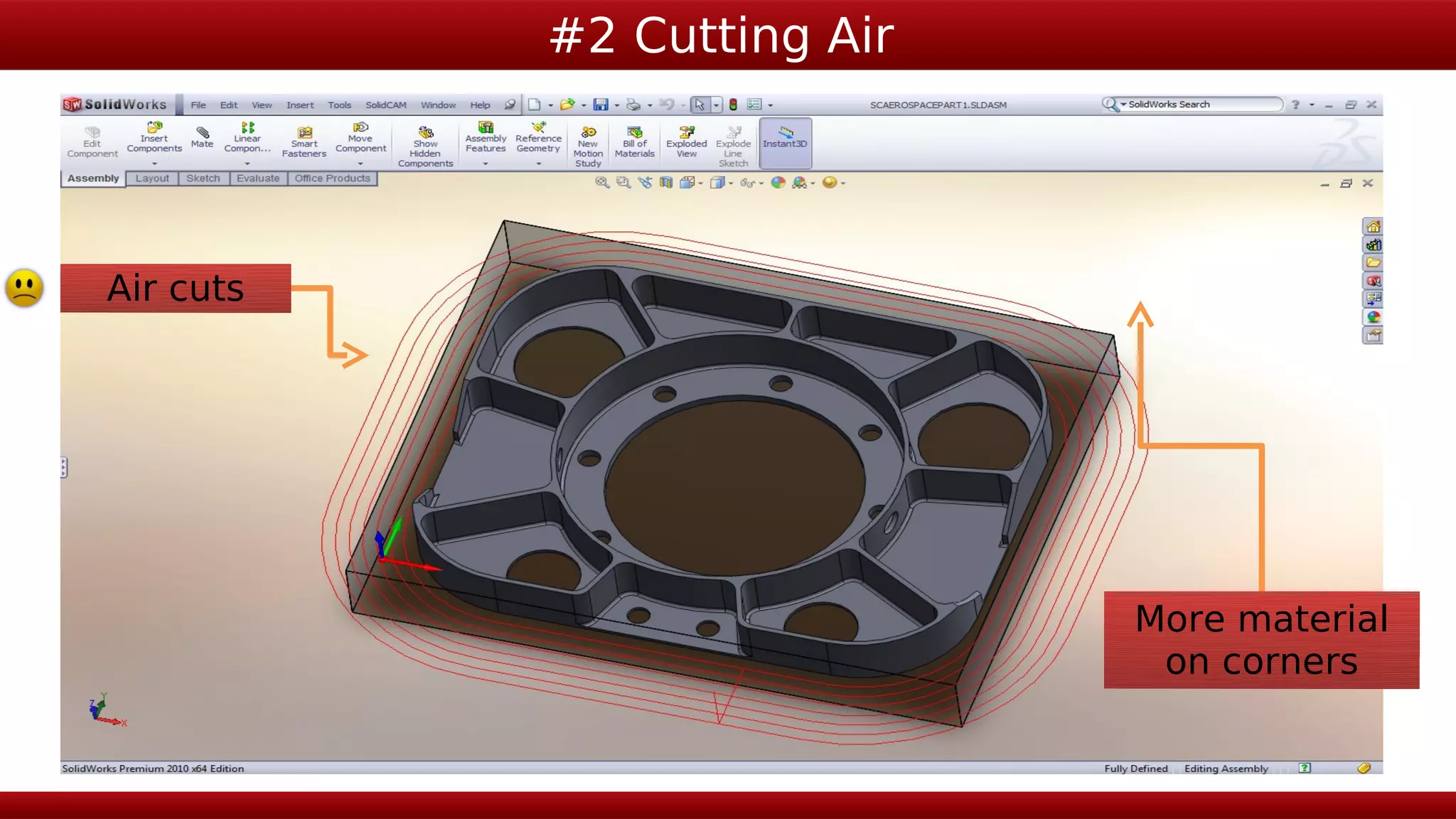

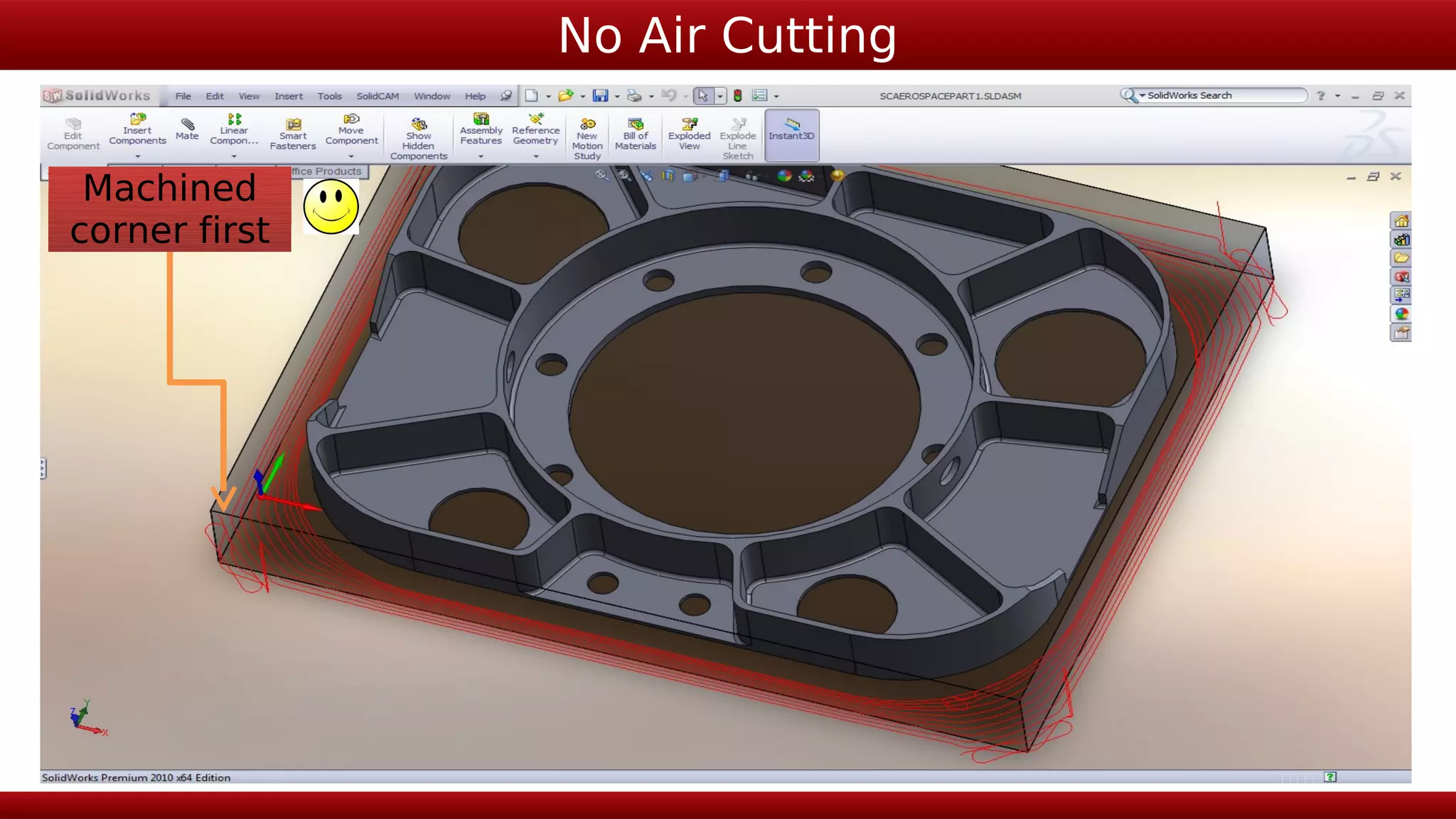

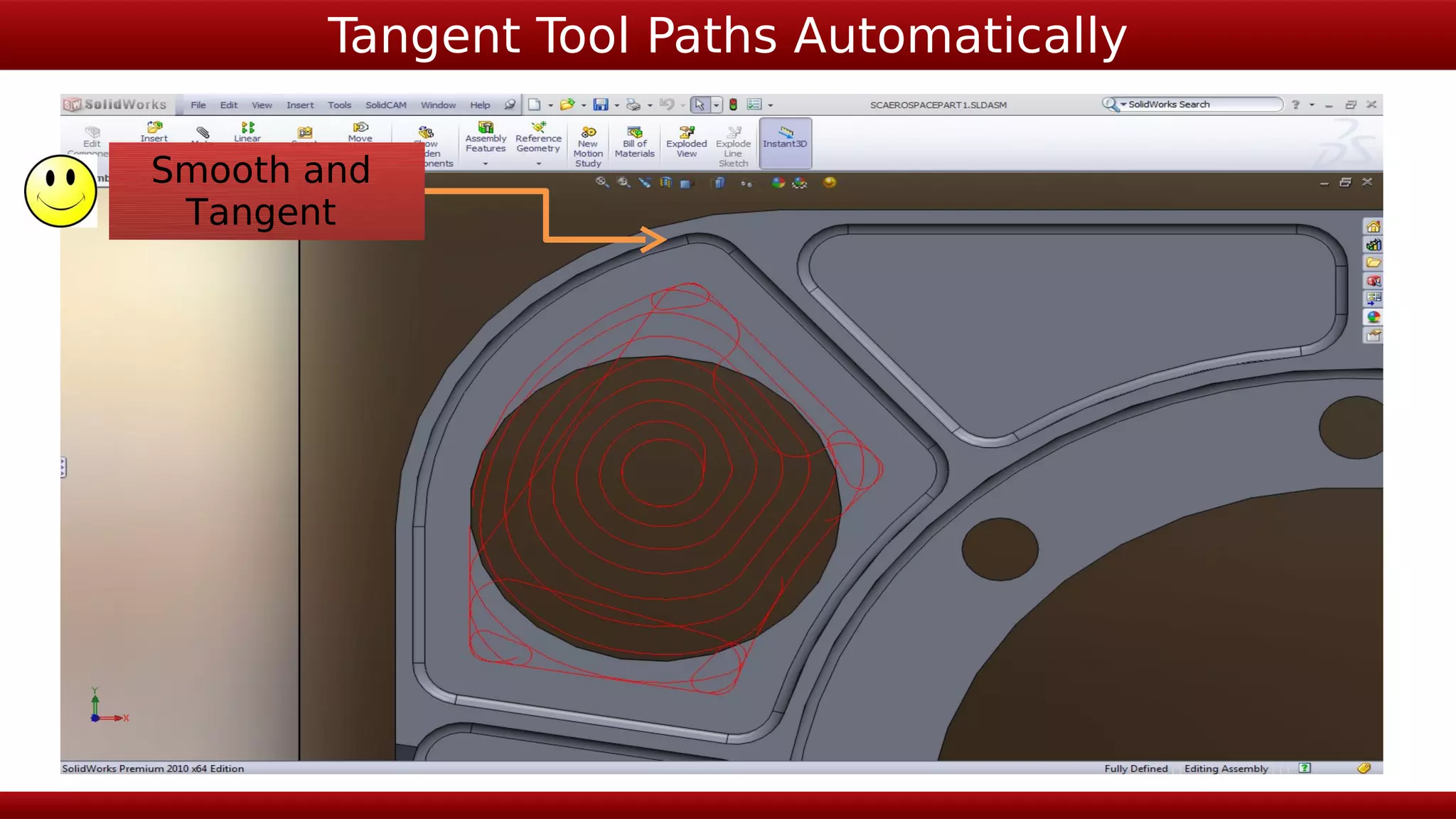

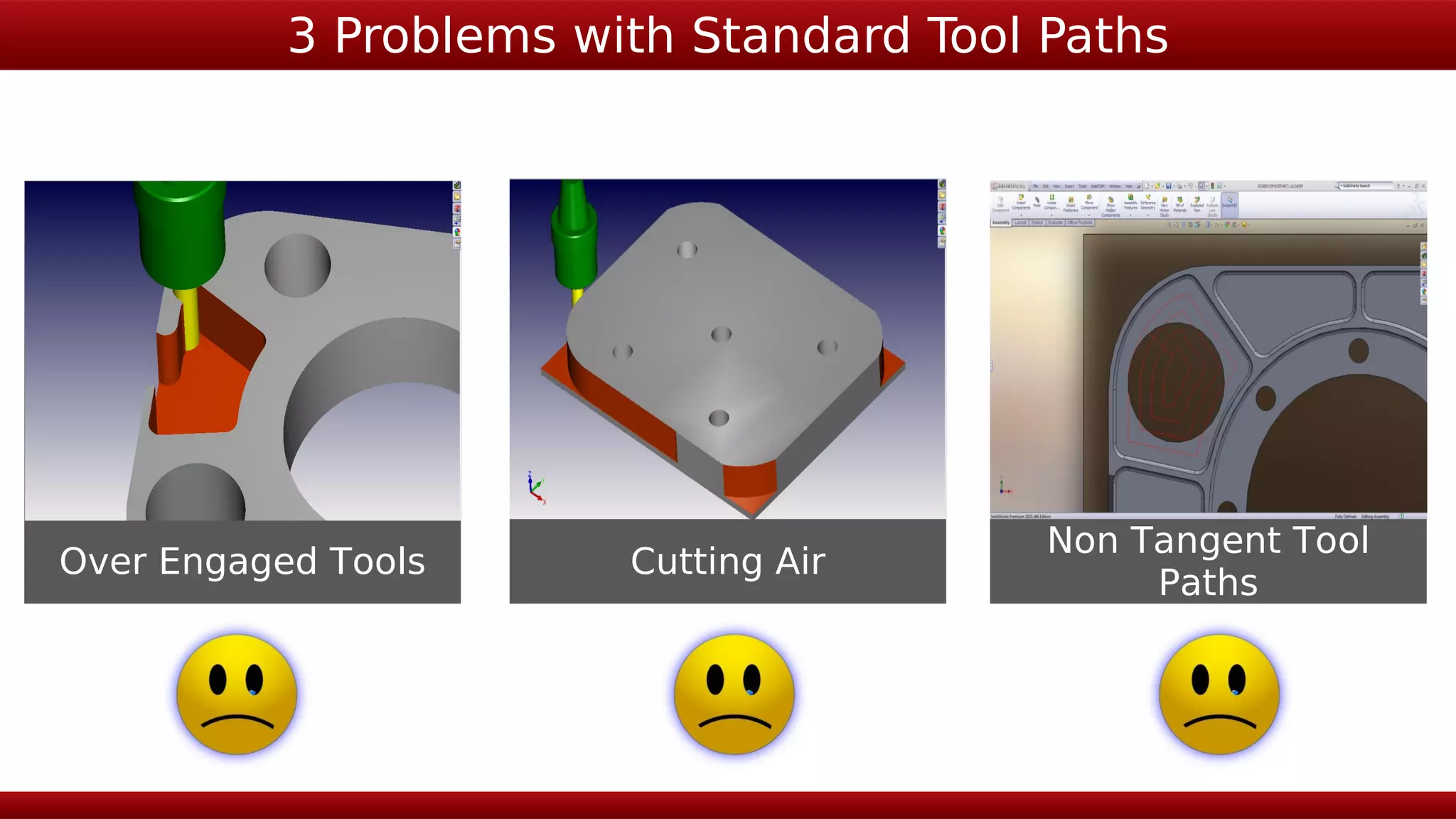

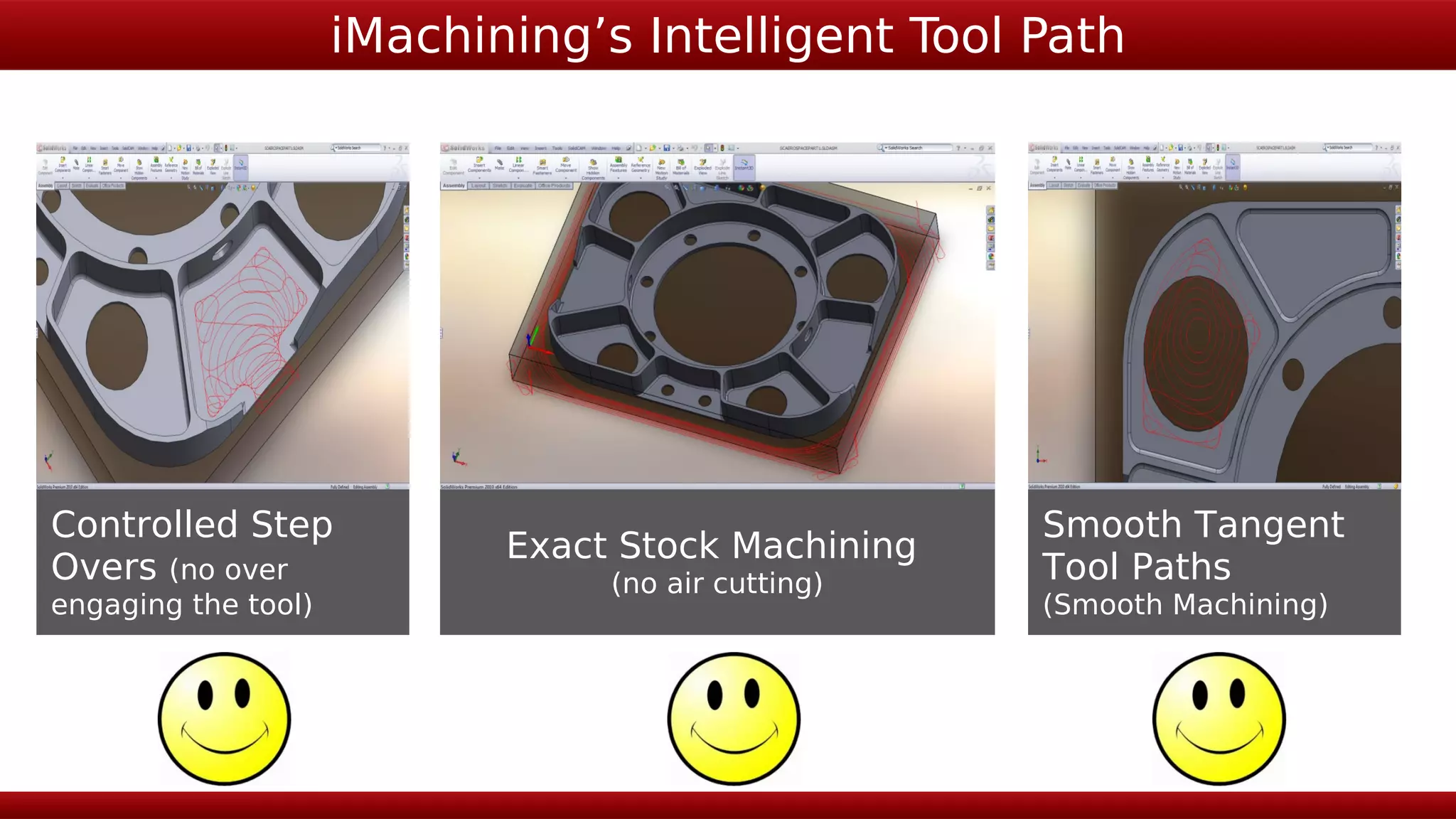

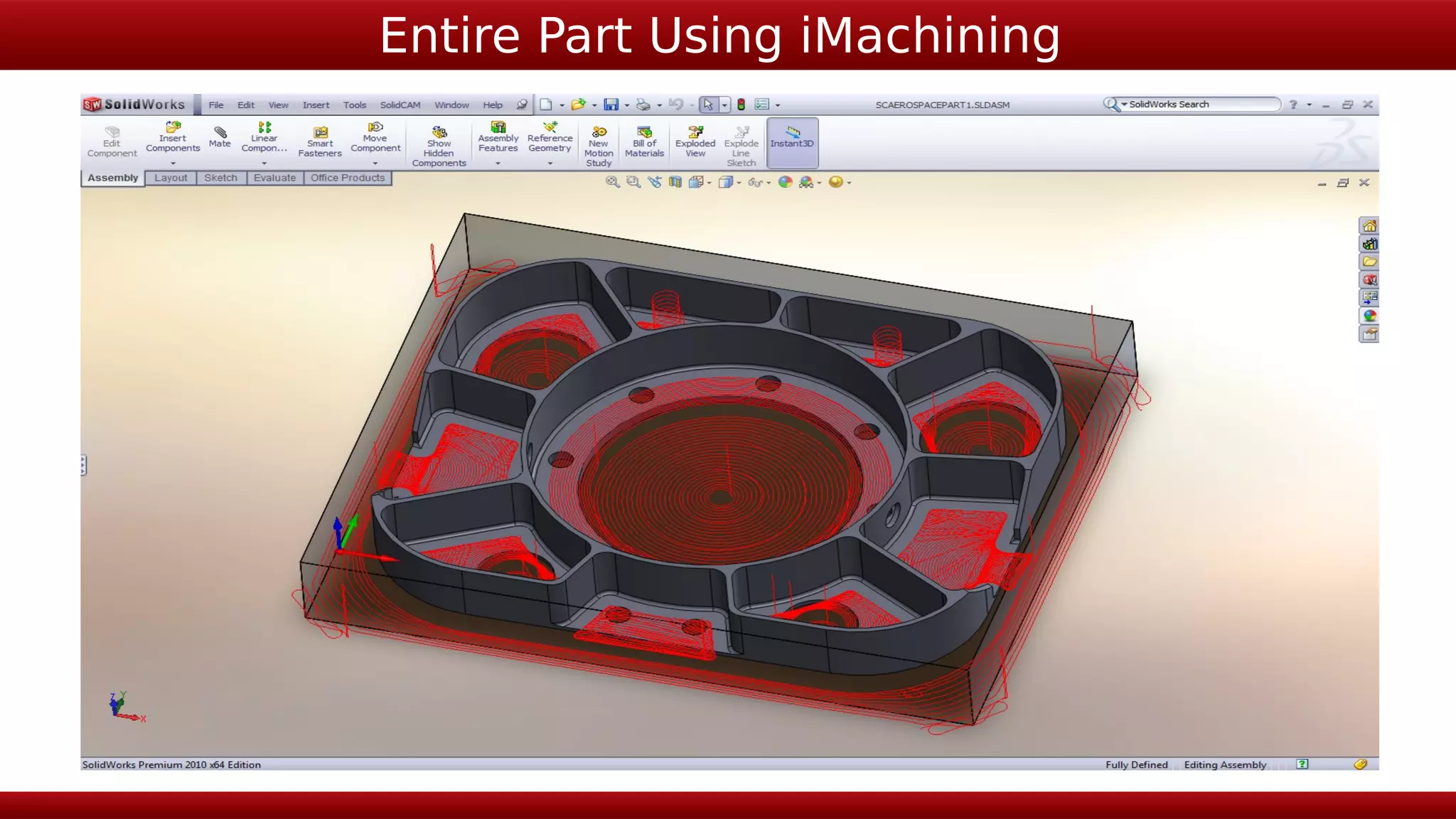

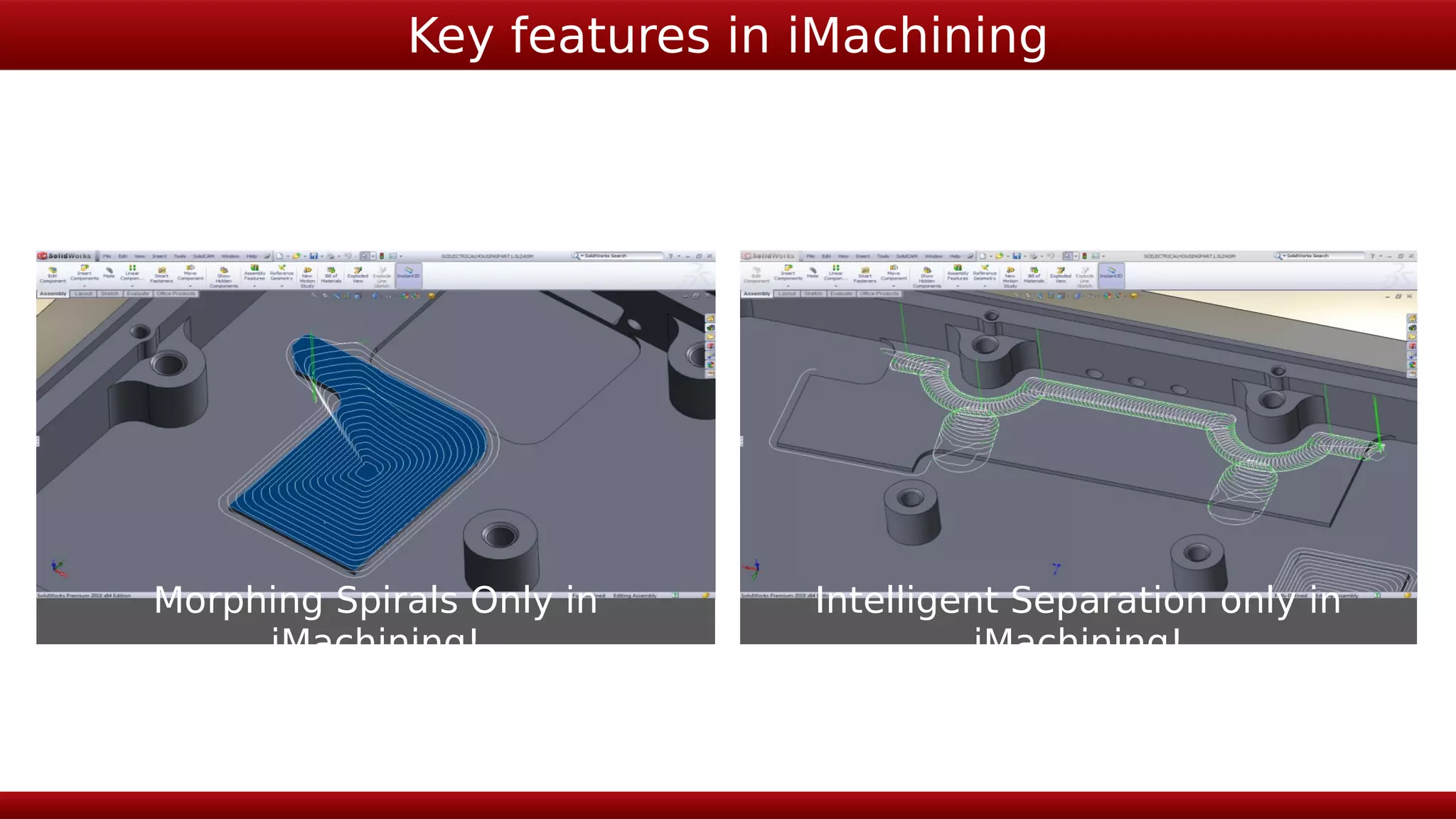

iMachining provides an intelligent approach to CNC tool path planning that addresses 3 common problems with standard tool paths: over-engaged tools, cutting air, and non-tangent tool paths. It generates smooth, tangent tool paths for exact stock removal using controlled step overs and a single depth, eliminating over-engagement and air cutting. The technology enables machining an entire part without stopping using morphing spirals and intelligent separation between features.