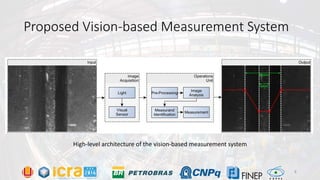

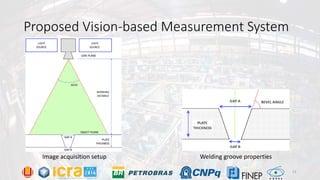

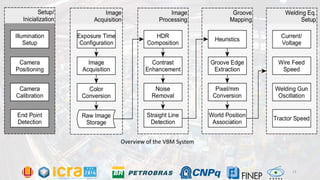

1) The document describes a robotic vision system for mapping welding grooves on metallic surfaces using machine vision techniques without complex optical setups.

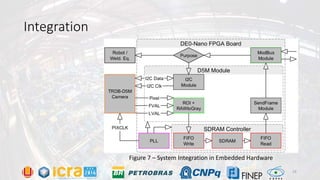

2) A prototype system was developed using an FPGA, camera, and welding robot to autonomously map groove dimensions in real-time to improve welding quality over manual processes.

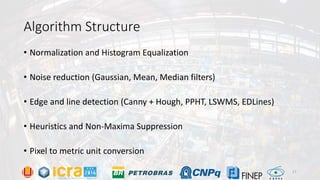

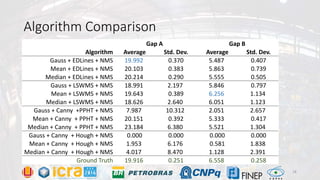

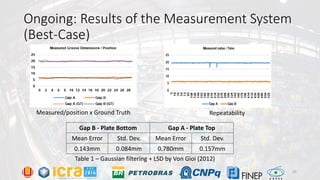

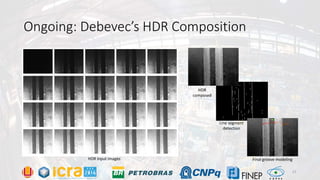

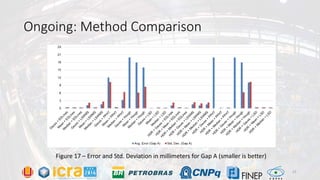

3) Experimental results found the Gaussian filtering and line segment detection approach achieved sub-millimeter accuracy and repeatability in measuring groove widths, outperforming other filtering and edge detection algorithms tested. Further improvements to lighting and image processing are ongoing.