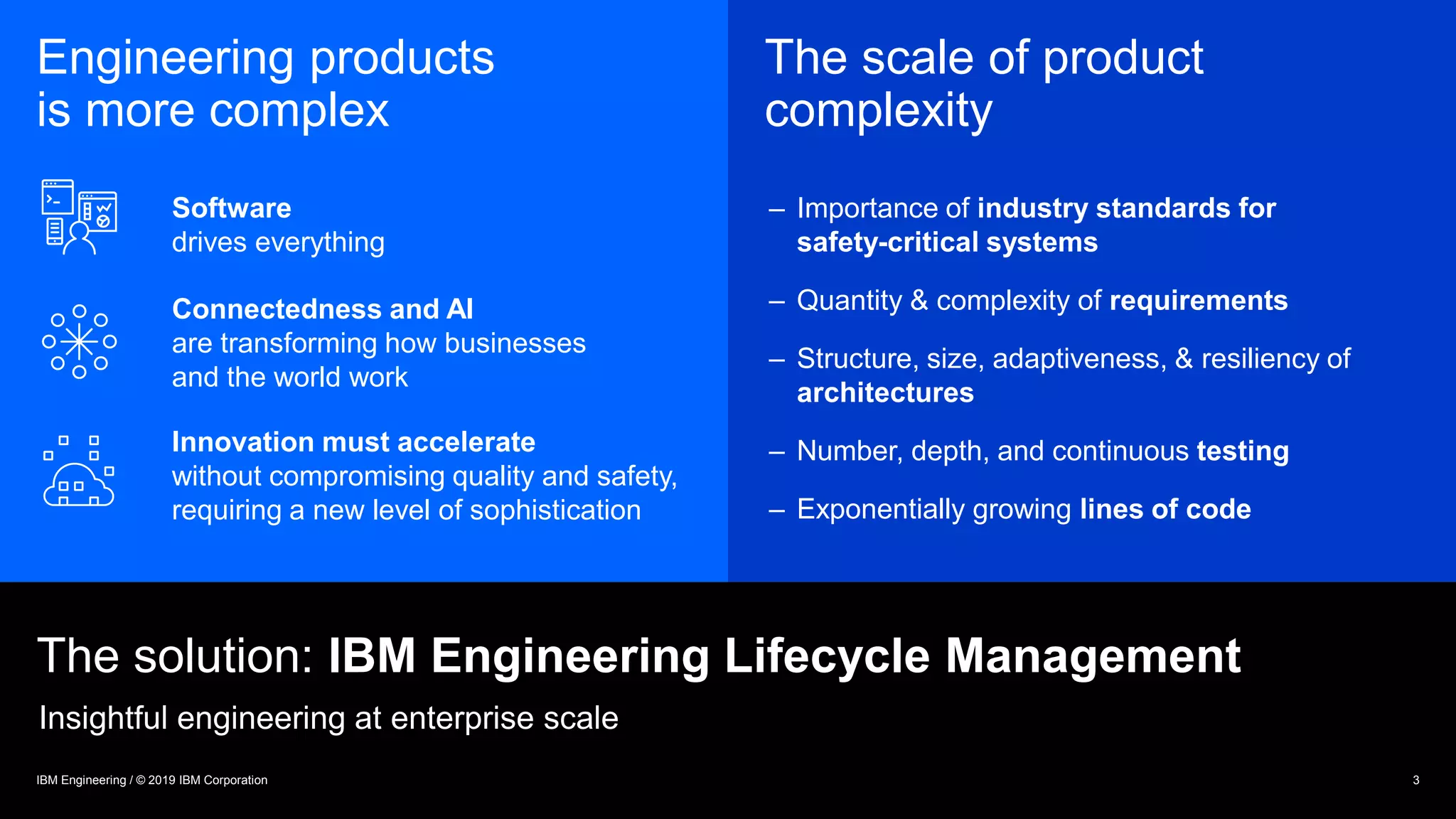

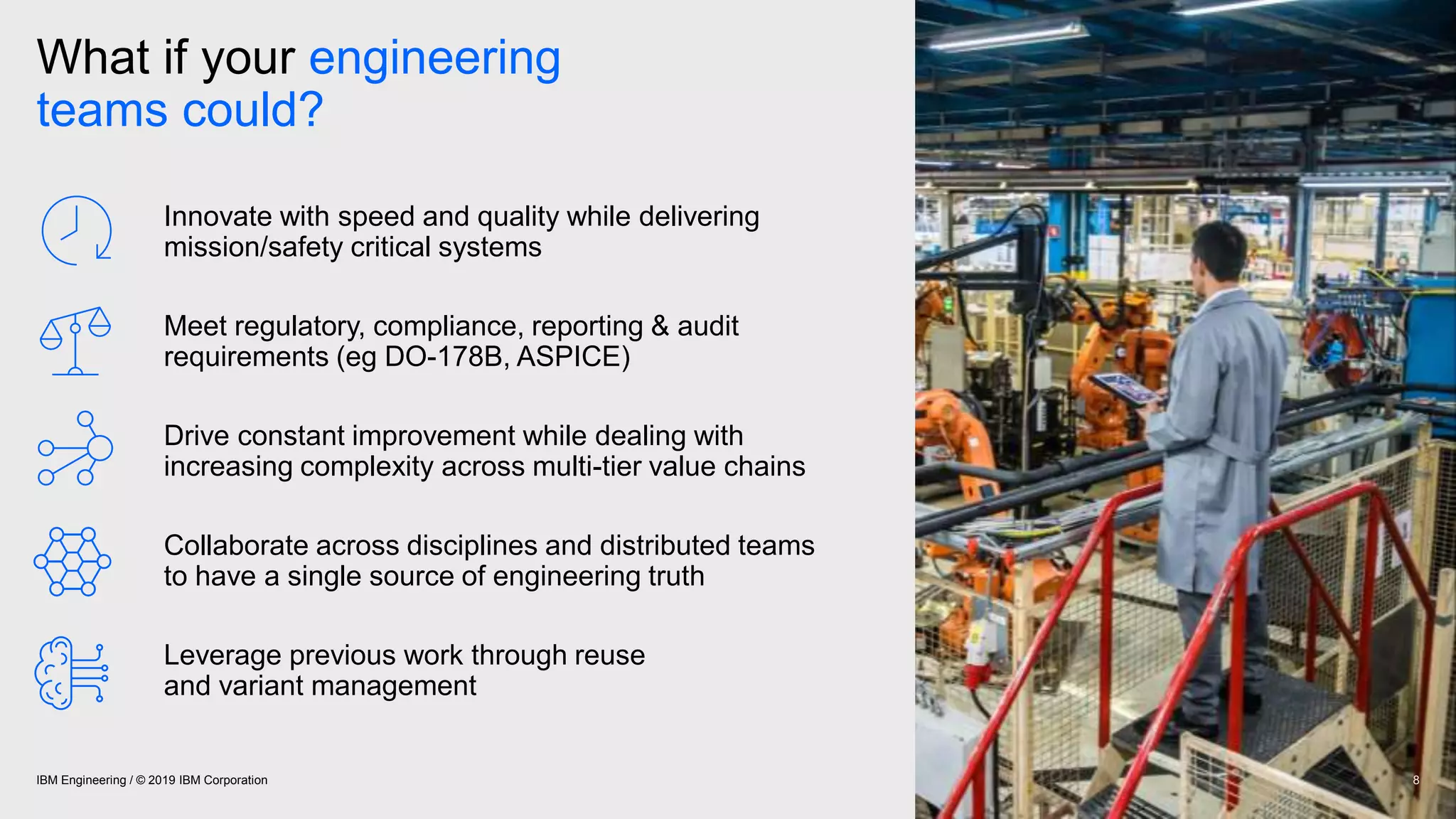

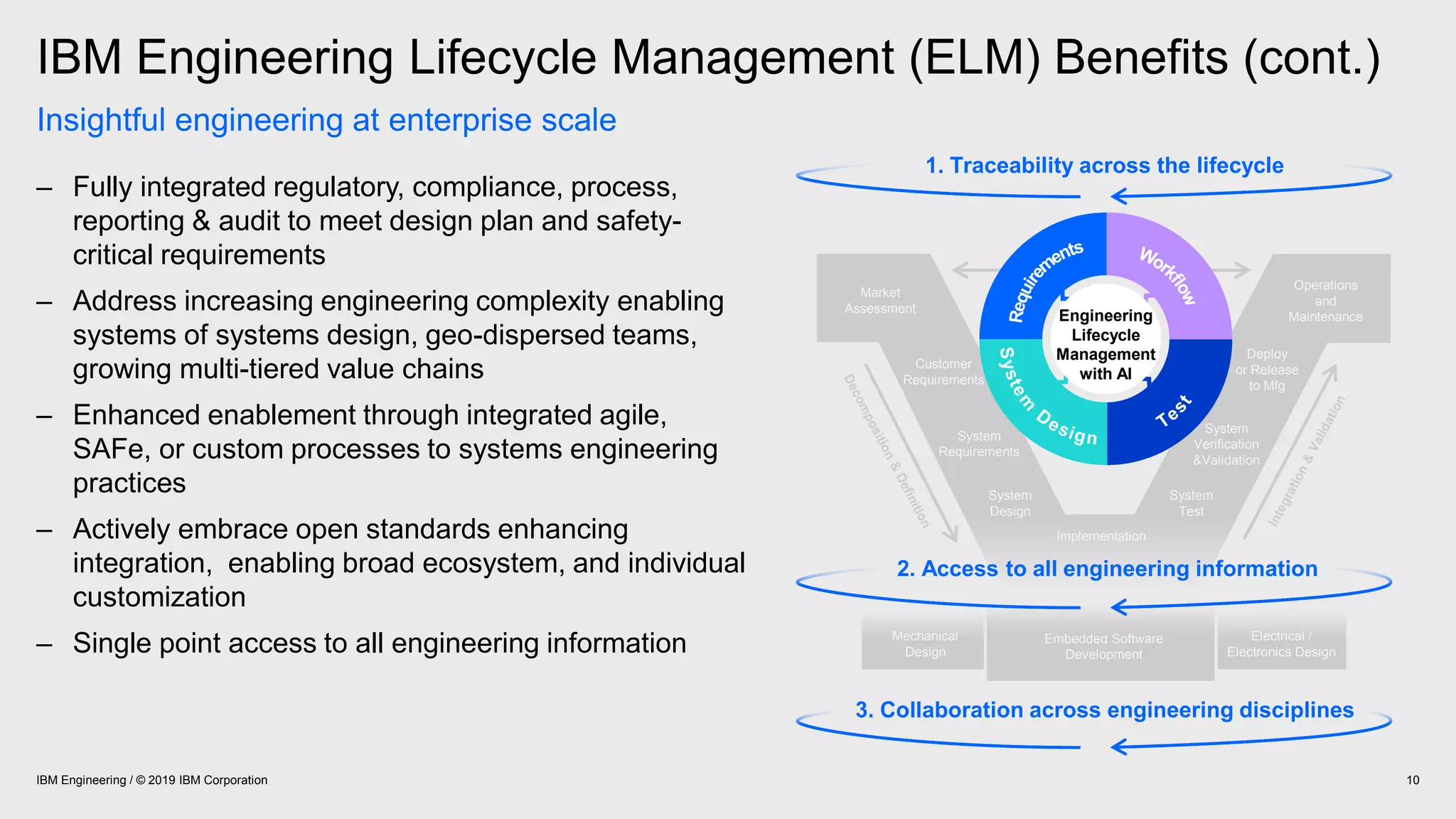

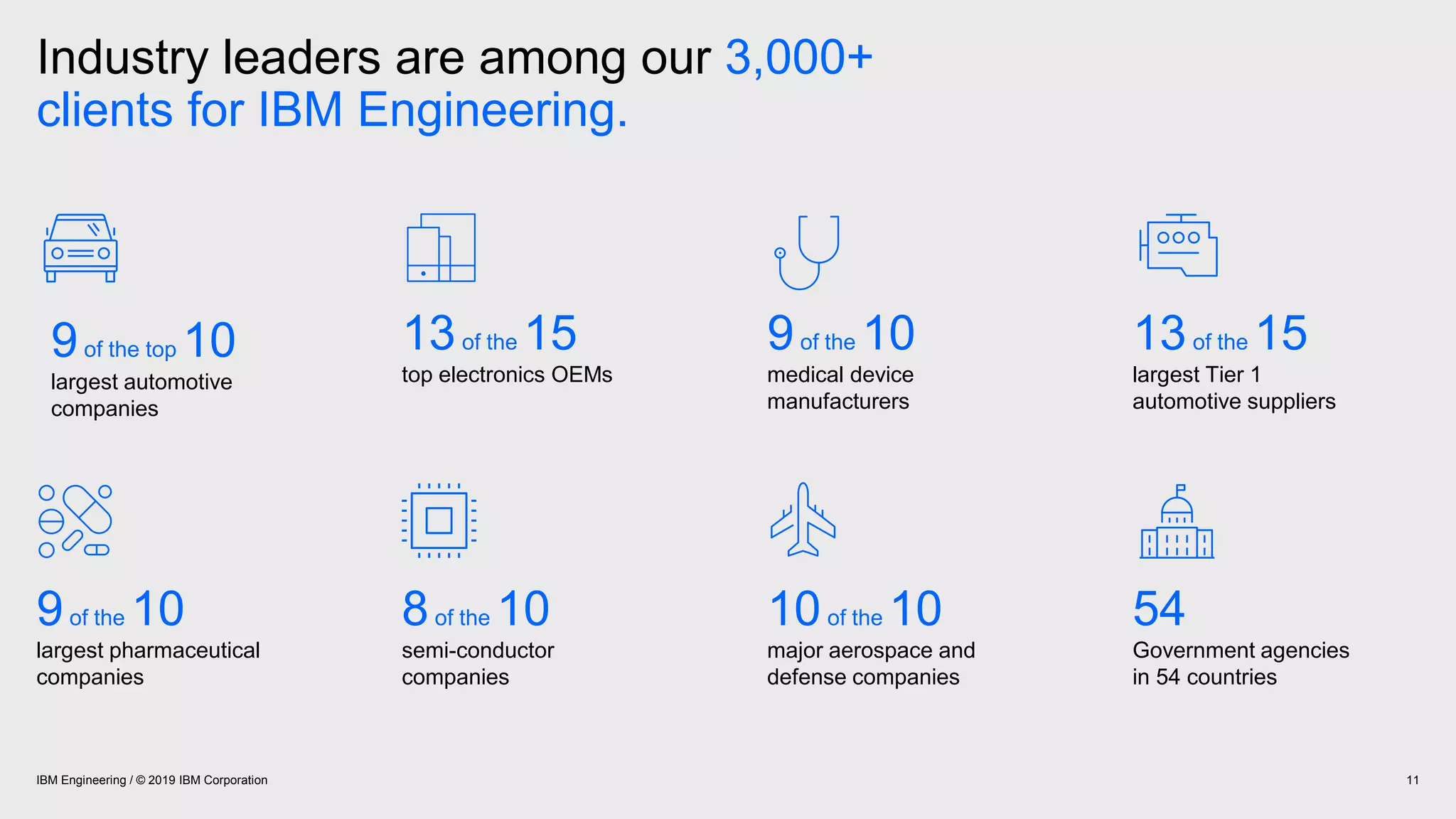

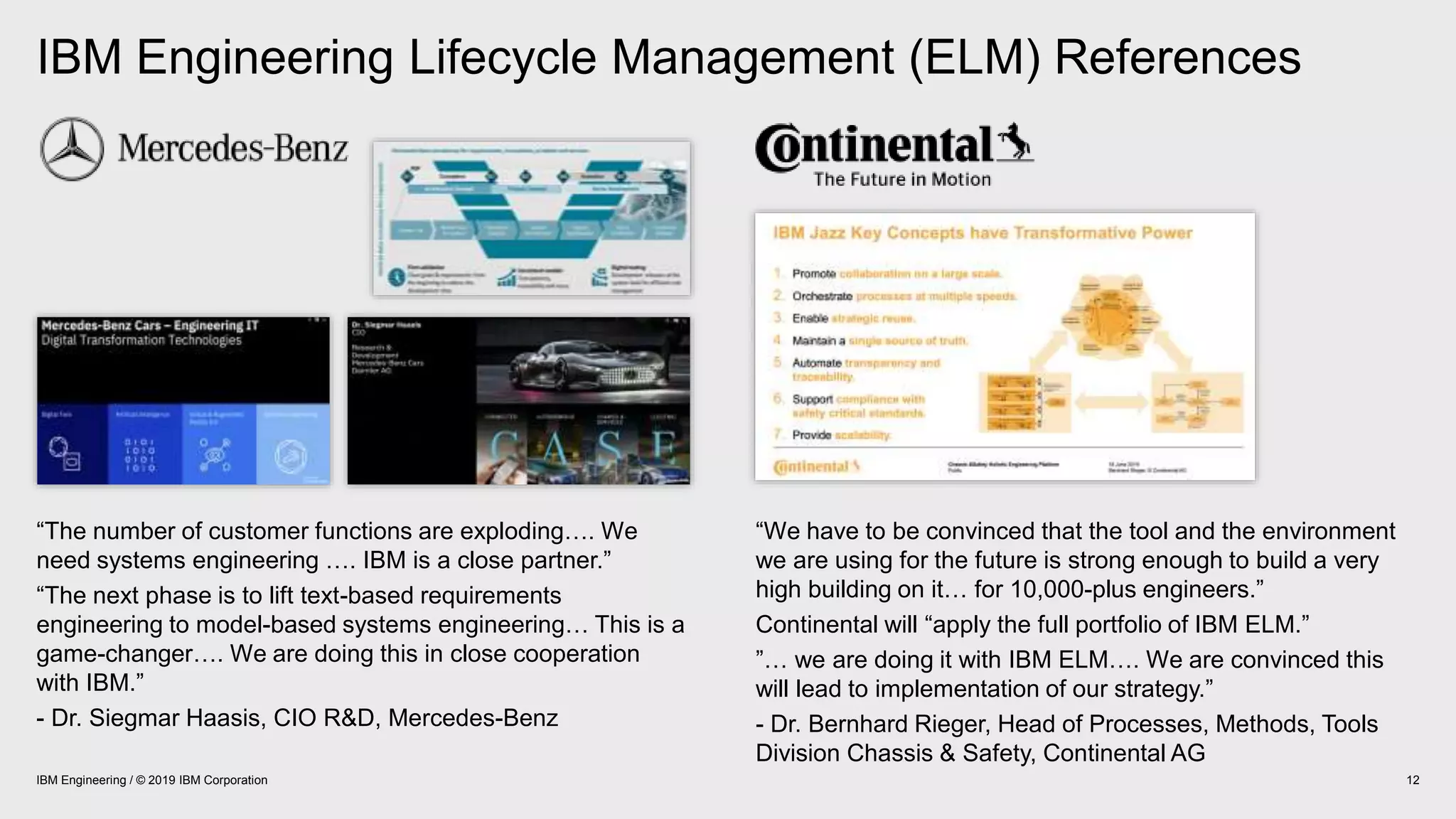

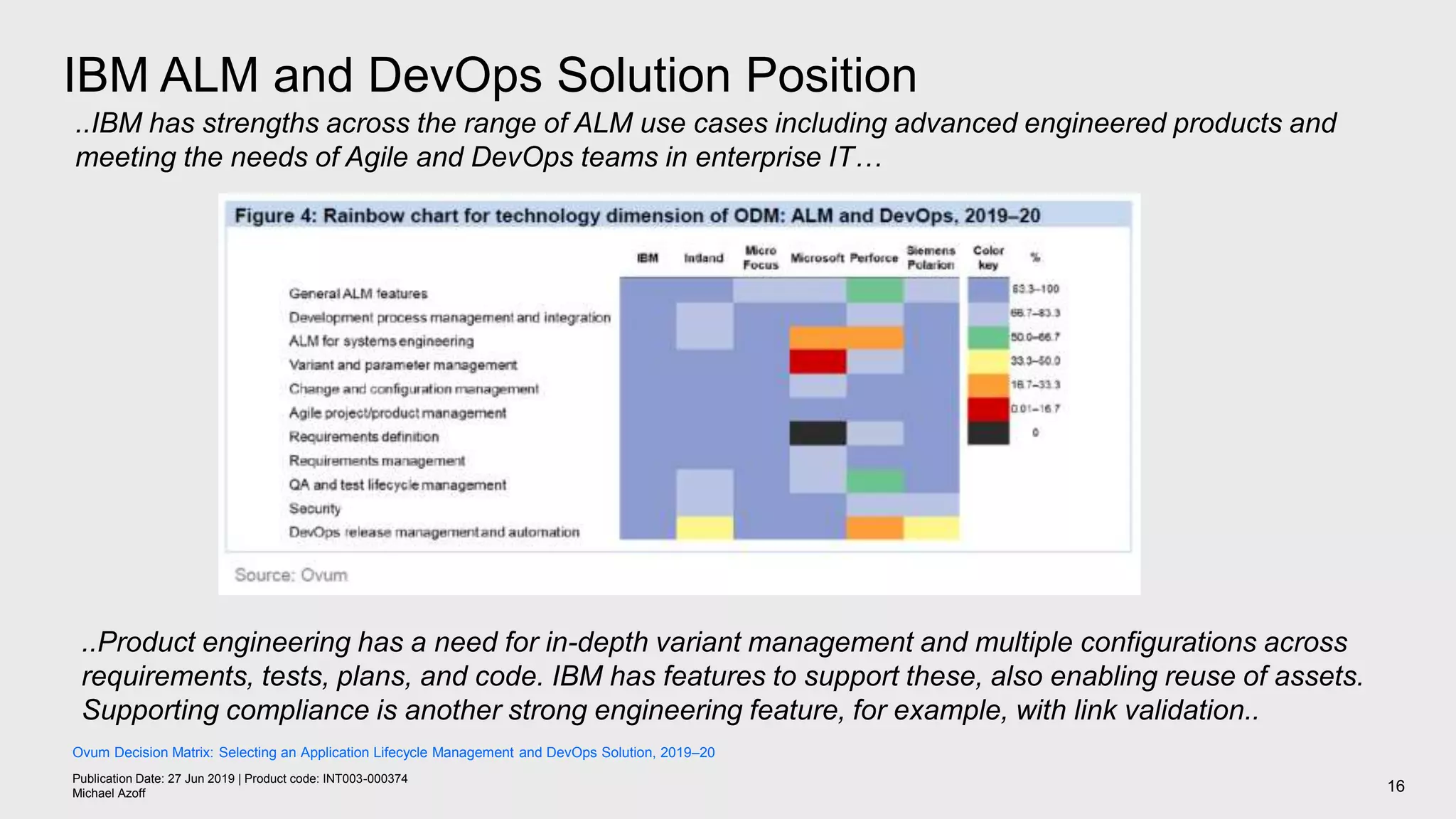

The document provides an overview of IBM Engineering Lifecycle Management (ELM) and its benefits in addressing the complexities of modern engineering, particularly in industries like automotive, aerospace, and medical devices. It emphasizes the necessity for improved collaboration, innovation, and compliance in the face of rapidly growing data and connected products. Case studies highlight successful implementations by organizations such as Mahindra and Jaguar Land Rover, showcasing significant reductions in time to market and improvements in product quality.