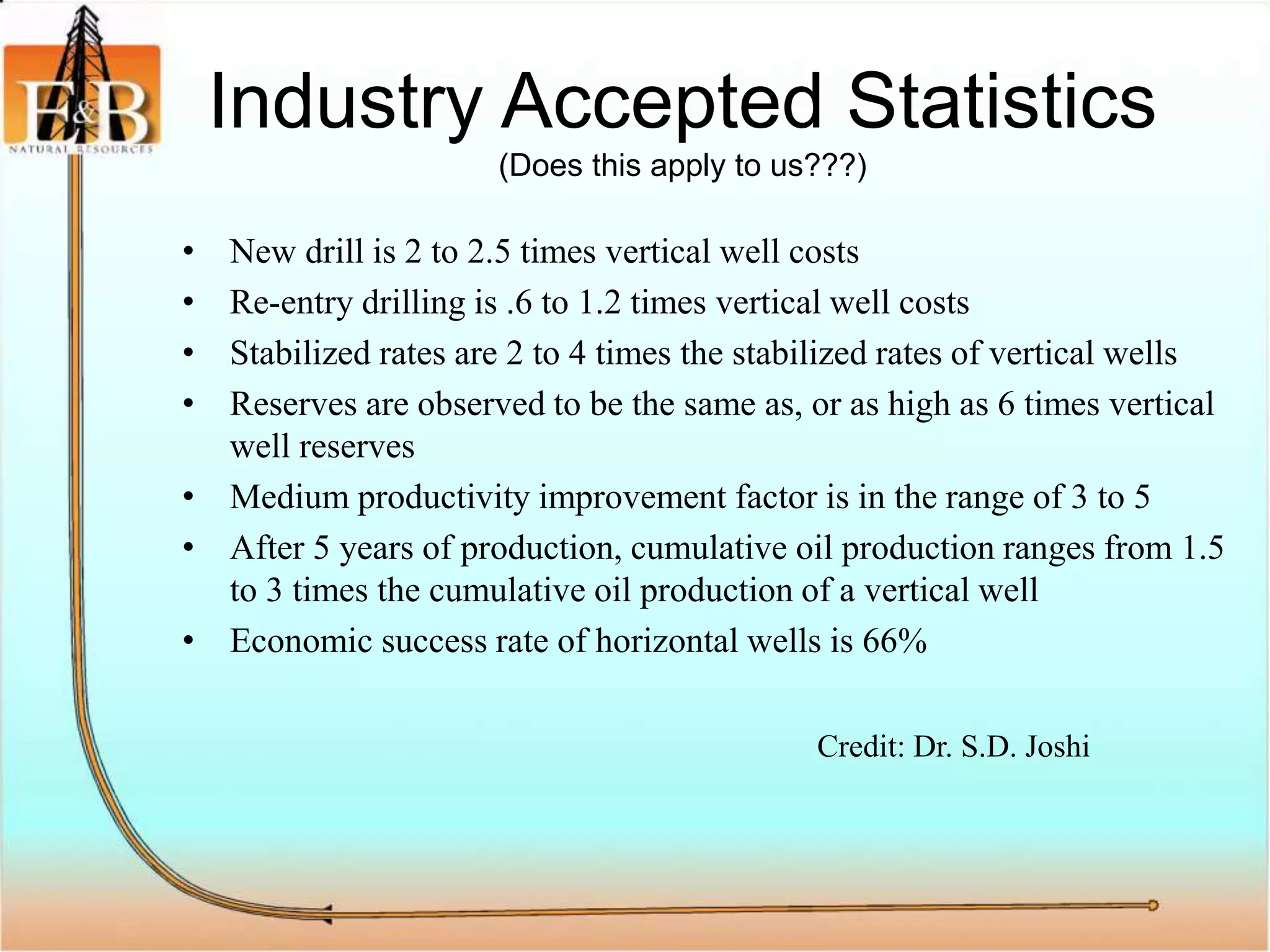

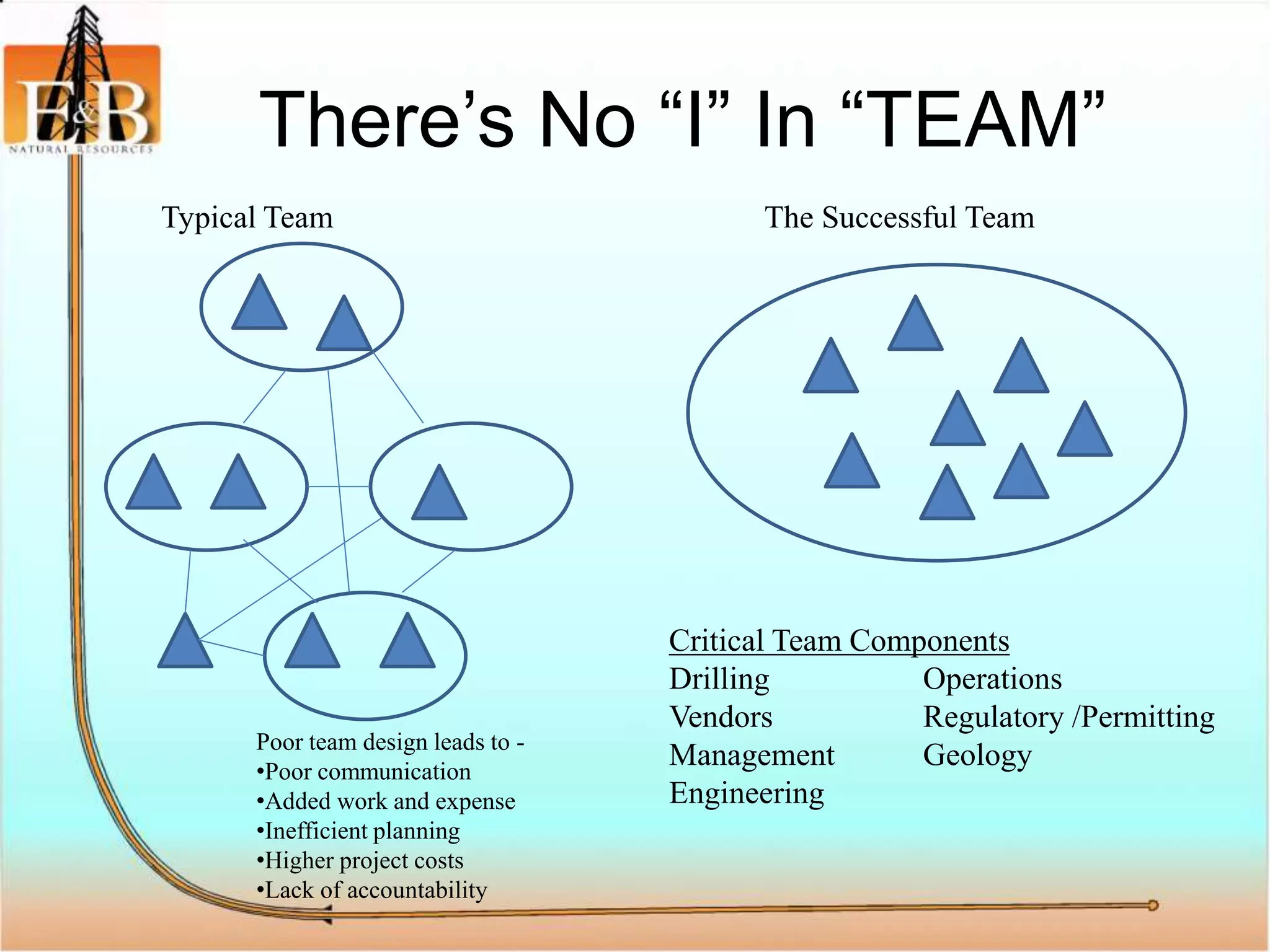

This document provides a checklist for successfully planning and drilling horizontal wells. It discusses common misconceptions about horizontal drilling and emphasizes the importance of thorough technical and economic analysis before deciding to drill horizontally. It also stresses the critical role of a well-defined team with clear communication and accountability. The checklist covers defining the project scope, conducting risk analysis, assembling the right team, creating detailed planning documents, effective communication strategies, and post-mortem reviews. Overall, it argues that horizontal wells require more rigorous planning and management than vertical wells to achieve success.