This document provides an overview and instructions for installing, configuring, operating, and troubleshooting the UDC2500 Universal Digital Controller. It describes the controller's displays, keys, software, mounting considerations, wiring diagrams, configuration groups and parameters, operating modes, setpoints, alarms, and tuning functions. Safety symbols are defined that are used in the document.

![Configuration

38 UDC2500 Universal Digital Controller Product Manual 8/05

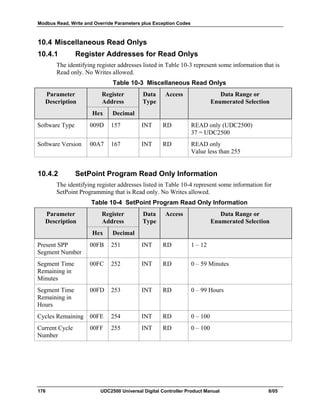

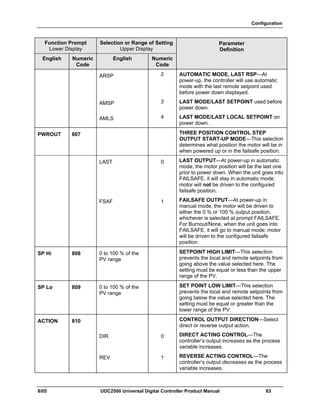

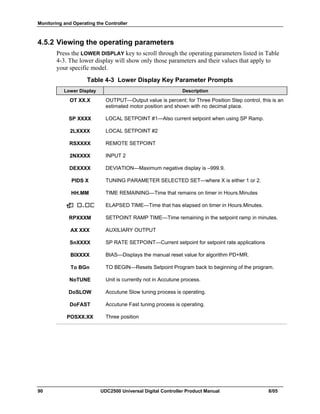

3.5 SP Ramp Set Up Group

Introduction

Set Point Ramp, Set Point Programs and Set Point Rates can be configured in this group.

A single Setpoint Ramp [SP RAMP] can be configured to occur between the current local

setpoint and a final local setpoint over a time interval of from 1 to 255 minutes.

A Set Point Rate [SPRATE] lets you configure a specific rate of change for any local

setpoint change.

A single Set Point Program [SP PROG] with up to 12 segments can be configured.

For more information on Set Point Rate, Ramp and Programming, see Sections 4.18

through 4.21.

You can start and stop the ramp/program using the RUN/HOLD key.

PV Hot Start is a configurable feature and means that, at initialization, the setpoint is set

to the current PV value and the Ramp or Rate or Program then starts from this value.

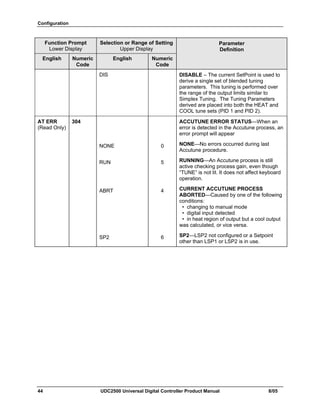

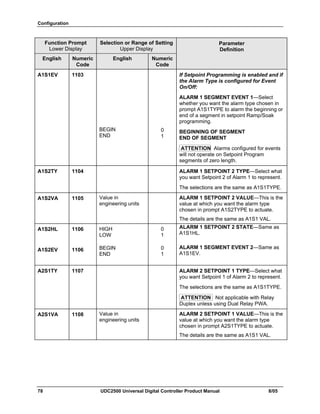

Function Prompts

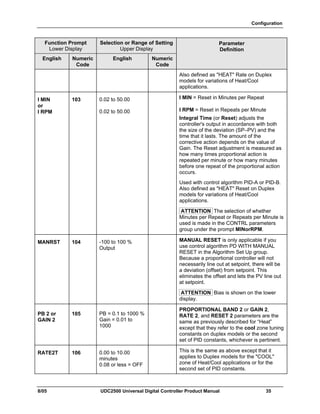

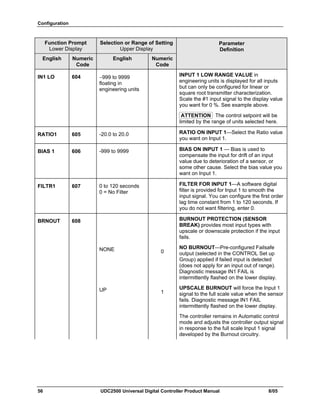

Table 3-5 SPRAMP Group (Numeric Code 200) Function Prompts

Function Prompt

Lower Display

Selection or Range of Setting

Upper Display

English Numeri

c Code

English Numeric

Code

Parameter

Definition

SP RAMP

SP Program

must be

disabled for

SP Ramp

prompts to

appear

201 DIS

ENAB

0

1

SINGLE SETPOINT RAMP—Make a

selection to enable or disable the setpoint

ramp function. Make sure you configure a

ramp time and a final setpoint value.

SP Programming must be disabled.

DISABLE SETPOINT RAMP—Disables the

setpoint ramp option.

ENABLE SETPOINT RAMP—Allows the

single setpoint ramp prompts to be shown.

TI MIN 202 0 to 255 minutes SETPOINT RAMP TIME—Enter the number

of minutes desired to reach the final setpoint.

A ramp time of “0” implies an immediate

change of setpoint.](https://image.slidesharecdn.com/honeywelludc2500-130826022228-phpapp02/85/Honeywell-udc-2500-48-320.jpg)

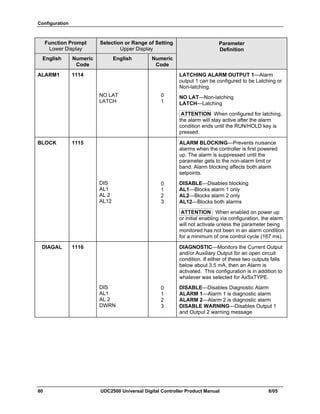

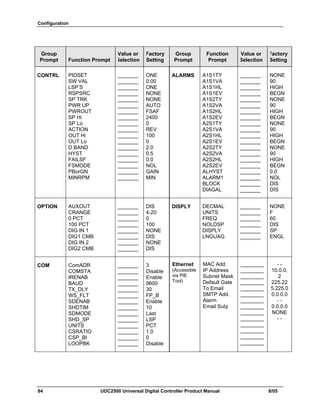

![Monitoring and Operating the Controller

8/05 UDC2500 Universal Digital Controller Product Manual 89

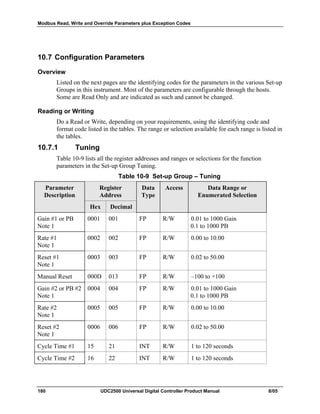

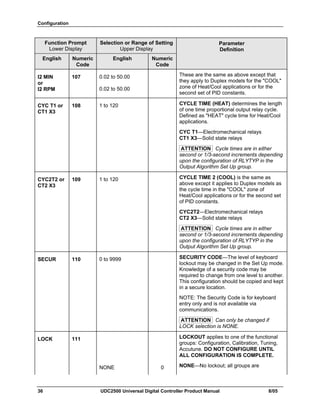

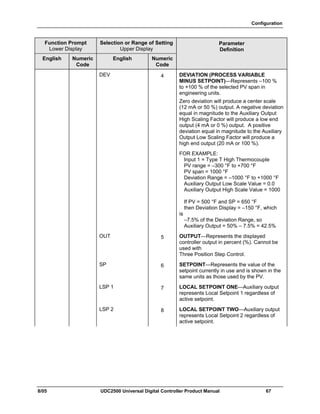

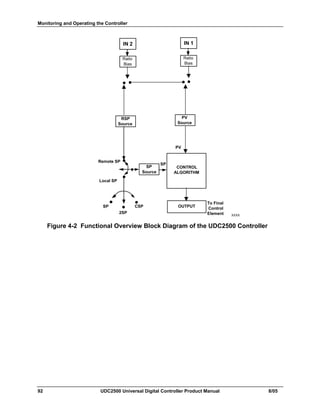

4.5 Monitoring Your Controller

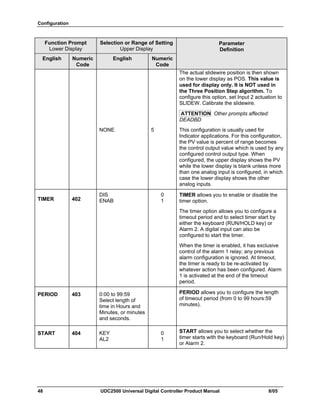

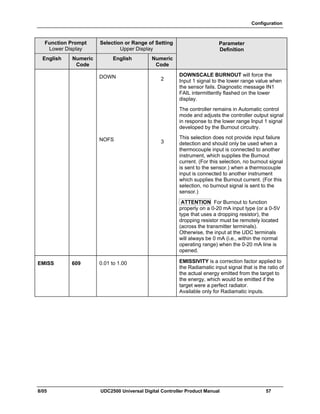

4.5.1 Annunciators

The following annunciator functions have been provided to help monitor the controller:

Table 4-2 Annunciators

Annunciator Indication

ALM 1 2 A visual indication of each alarm

Blinking 1 indicates alarm latched and needs to be acknowledged (by

pressing the RUN/HOLD key before extinguishing when the alarm

condition ends

OUT 1 2 A visual indication of the control relays

A or M A visual indication of the mode of the controller (Dual display model only)

A—Automatic Mode

M—Manual Mode

[None], F or C A visual indication of the temperature units

[None]—No temperature unit annunciator

F—Degrees Fahrenheit

C—Degrees Celsius

L or R A visual indication of setpoint being used

L— Local Setpoint is active

R— RSP or LSP 2 is active

The upper display is used to show other annunciator functions

TUNE—Accutuning in progress

RUN—SP Program in progress

HOLD—SP Program on hold

CSP—Controlling to the Computer Setpoint

LOOPBK—Loopback Test running](https://image.slidesharecdn.com/honeywelludc2500-130826022228-phpapp02/85/Honeywell-udc-2500-99-320.jpg)

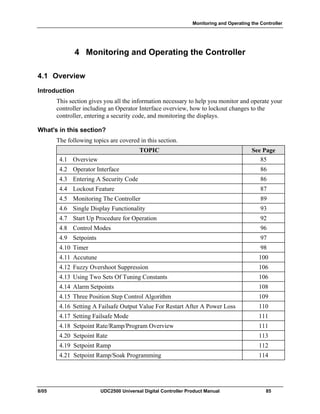

![Troubleshooting/Service

8/05 UDC2500 Universal Digital Controller Product Manual 157

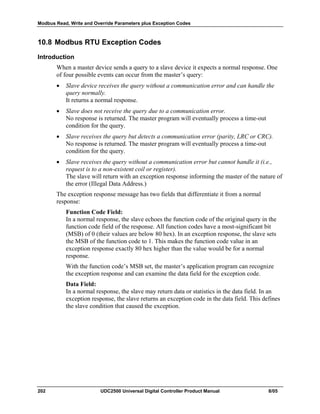

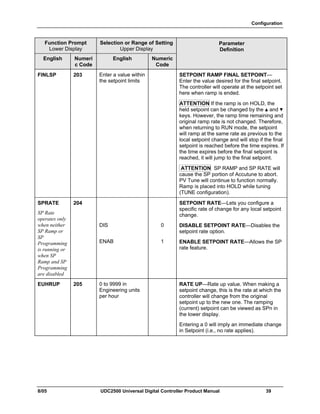

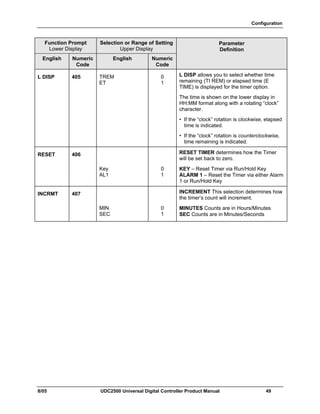

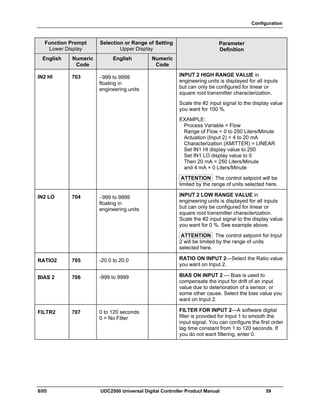

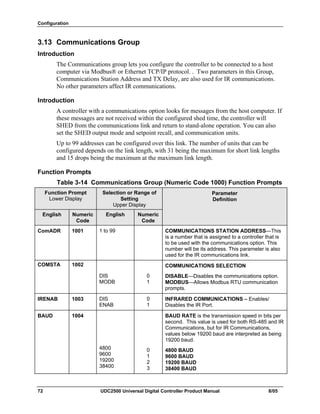

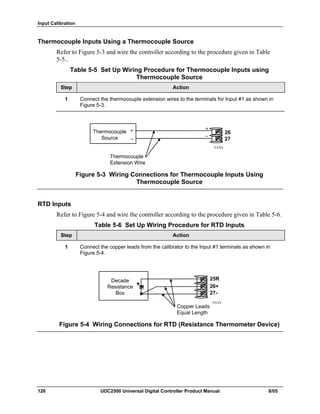

Procedure #7

Table 7-11 explains how to troubleshoot a Keyboard failure.

Table 7-11 Troubleshooting a Keyboard Failure

Step What to do How to do it

1 Make sure the keyboard is

connected properly to the

MCU/output and power/input

boards.

Withdraw the chassis from the case

and visually inspect the connection.

2 Controller Keyboard or specific keys

may be LOCKED OUT via the

security code.

Use your four-digit security code

number to change the lockout level.

Refer to Section 3 – Configuration.

3 Run the keyboard test. Press the [SET UP] key and hold in,

then press the [FUNCTION] key at the

same time. The controller will run a

display test. Then you will see:

TRY ALL

Lower Display

KEYS

Upper Display

Press each key. If it works, the key

name will appear in the lower display.

4 Replace the display/keyboard if any

keys do not function.

Refer to “Parts Replacement

Procedures” in this section.](https://image.slidesharecdn.com/honeywelludc2500-130826022228-phpapp02/85/Honeywell-udc-2500-167-320.jpg)

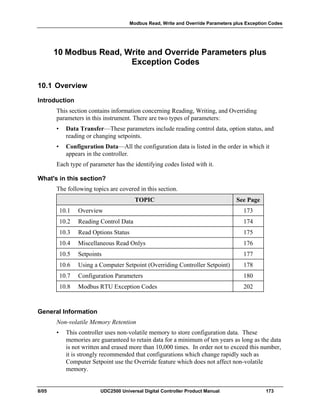

![Troubleshooting/Service

158 UDC2500 Universal Digital Controller Product Manual 8/05

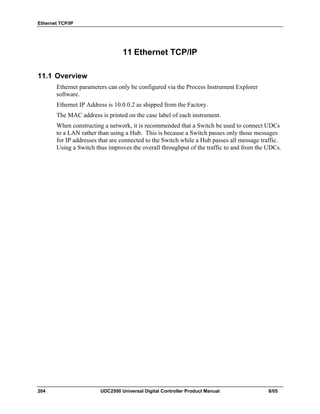

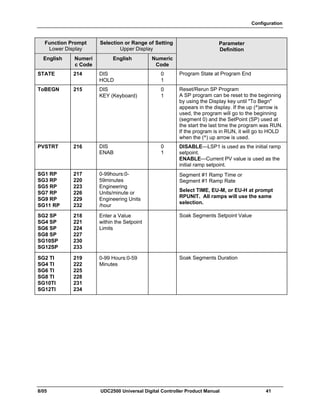

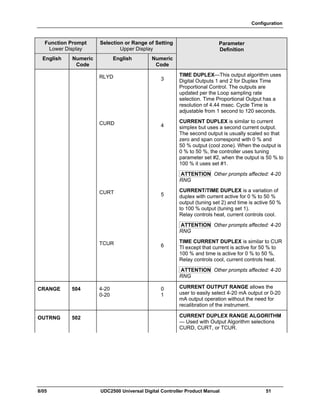

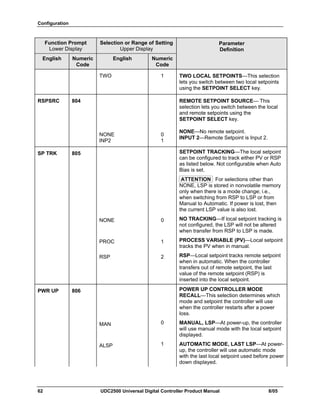

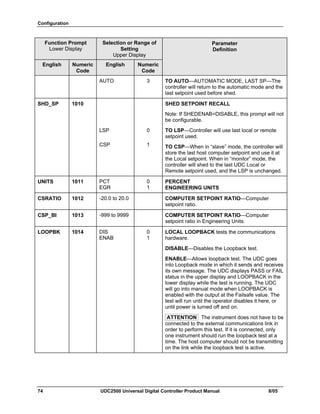

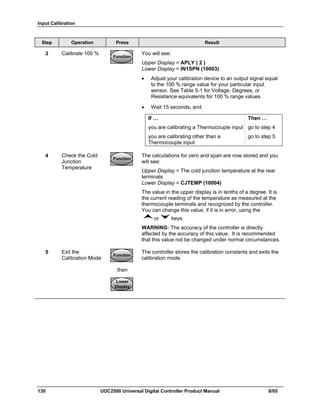

Procedure #8

Table 7-11 explains how to troubleshoot a Communications failure

Table 7-12 Troubleshooting a RS-485 Communications Failure

Step What to do How to do it

1 Check the Address Number,

ComState and Baud Rate settings.

See Section 3.13.

2 Check the field wiring and

termination resistor.

Using an ohm meter, check the resistance across

the communications rear terminals. See Section

2.7 for wiring diagrams.

3 Make sure the Communications

Printed Wiring Board is installed

properly in the controller.

Withdraw the chassis from the case and inspect the

board. See the exploded view (Figure 8-1) for

location of the board. Return the chassis to the

case.

4 Determine if the Communications

board is faulty by running a LOCAL

LOOPBACK TEST.

If the test fails, replace the board.

If the test passes, the problem is

most likely elsewhere in the

communications network.

Disconnect the communications cable from the rear

terminals. Run the Local Loopback Test.

Press [SET UP] until you see:

COM

Lower Display

SET UP

Upper Display

Press [FUNCTION] until you see:

LOOPBACK

Lower Display

DISABLE

Upper Display

Press or you will see:

LOOPBACK

Lower Display

ENABLE

Upper Display

The test will run until the operator disables it here.](https://image.slidesharecdn.com/honeywelludc2500-130826022228-phpapp02/85/Honeywell-udc-2500-168-320.jpg)

![Troubleshooting/Service

160 UDC2500 Universal Digital Controller Product Manual 8/05

6 Change Controller

7.8 Restoring Factory Configuration

Introduction

This procedure restores the configuration of the instrument back to the Factory Settings

per Section 3.16.

ATTENTION: Restoring the factory configuration overwrites all user-entered

configuration changes. This procedure cannot be undone, it is a one-way process.

Table 7-15 explains how to restore Factory Configuration.

Table 7-15 Restoring Factory Configuration

Step What to do

1 Turn off the power to the instrument for at least five seconds.

2 Turn the power back on and simultaneously press the “FUNCTION” and

keys. This must be done while “TEST DONE” is being displayed.

3 If step 2 was performed correctly, the instrument will now display “UDC”

[Upper] “UPDATE” [Lower].

4 Press the FUNCTION Key. The instrument will now display “DIS” [Upper]

“RESTORE” [Lower].

5 Press the key. The instrument will now display “CFG” [Upper]

“RESTORE” [Lower].

6 Press the FUNCTION Key. The instrument will now display “DOIN”

“RESTORE”

7 When the instrument finishes the restore operation, it automatically resets

itself and restarts in the product mode. The instrument configuration will

now be the same as it was when the instrument left the factory and all user-

entered configurations since that time have been overwritten.](https://image.slidesharecdn.com/honeywelludc2500-130826022228-phpapp02/85/Honeywell-udc-2500-170-320.jpg)