Homogenous pathway.pdf

- 1. Catalysis Science & Technology PAPER Cite this: Catal. Sci. Technol., 2021, 11, 2414 Received 6th January 2021, Accepted 19th January 2021 DOI: 10.1039/d1cy00039j rsc.li/catalysis Copper(I) oxide nanoparticle-mediated C–C couplings for synthesis of polyphenylenediethynylenes: evidence for a homogeneous catalytic pathway† Fathima F. Pary,‡a Ravi Teja Addanki Tirumala,‡b Marimuthu Andiappan *b and Toby L. Nelson *a During the last few decades, substantial attention has been devoted to copper and copper oxide nano- catalysts, due to copper's natural abundance, low cost and lower toxicity in comparison to precious metal- based nanoparticles. Cuprous oxide (Cu2O) nanoparticles show versatility in catalyzing and mediating car- bon–carbon (C–C) and carbon–heteroatom (e.g., C–N, C–O, C–S and C–Se) bond-forming reactions. Here, we demonstrate Cu2O nanoparticle-mediated oxidative C–C homocoupling reactions for the synthesis of polyphenylenediethynylenes under ligandless conditions, mild base and atmospheric air as the oxidant, with reasonable yields and moderate number-average molecular weights. Also, we demonstrate that, during the reaction, Cu2O nanoparticles undergo substrate-induced leaching to form homogeneous copper catalytic species. The leaching of catalytic species and in situ formation of copper complexes are characterized by electrospray ionization mass spectrometry, ultraviolet-visible extinction spectroscopy, transmission electron microscopy and reactor study. The results confirm the contribution of a homogeneous catalytic pathway for the oxidative C–C homocoupling reactions under the reaction conditions used. Introduction Metal and metal oxide nanoparticles (NPs) play a pivotal role as catalysts in organic synthesis due to their high reactivity, recyclability and sustainability.1–8 While recent years have witnessed a growing demand for nanocatalysts, there is also continuing controversy as to whether the catalysis occurs via the leached metal ions in solution (i.e., a homogeneous path- way), on the surface of the nanoparticle (i.e., a heterogeneous pathway), or as a cocktail-type semi-homogeneous pathway.8–26 Therefore, identification of the catalytic pathway remains one of the ongoing challenges within the field.9–25,27–30 Another area that remains as a major challenge is the development of earth-abundant and less toxic metal- based nanocatalysts as replacements for the conventional rare-earth and toxic palladium (Pd)-based catalysts.9–25,27–30 Environmentally benign copper-based nanoparticles have been attractive both in industry and academia because of cop- per's high natural abundance, low cost and comparatively less toxic nature, and it is a good alternative to rare and expensive metal and metal oxide catalysts, such as Pd-based catalysts.4 Specifically, copper oxide NPs have recently been reported as at- tractive catalysts for a diversity of bond formations, such as C– C, C–N, C–O, C–S and C–Se.12,24,31–39 For example, in our previ- ous contributions, we have demonstrated that cuprous oxide (Cu2O) NP-mediated C–C homocoupling of phenylacetylene (PA) exhibits ∼100% in situ yield towards the desired homocoupling product, diphenyldiacetylene (DPDA).34 Also, Cu2O NP-mediated C–C cross-coupling between PA and aryl halides exhibits more than 95% selectivity towards the desired cross-coupling product, diphenylacetylene (DPA), and less than 5% selectivity towards the undesired homocoupling product, DPDA.34 Conjugated oligo- and poly-ynes are an important class of materials, which have applications in electronic and photonic devices,40 such as materials for liquid crystal displays, thin- film transistors, light-emitting diodes and nanoscale molecu- lar wires.40–44 Conventional conjugated polymer syntheses are 2414 | Catal. Sci. Technol., 2021, 11, 2414–2421 This journal is © The Royal Society of Chemistry 2021 a Department of Chemistry, Oklahoma State University, Stillwater, Oklahoma 74078, USA b School of Chemical Engineering, Oklahoma State University, Stillwater, OK, USA. E-mail: mari.andiappan@okstate.edu † Electronic supplementary information (ESI) available. See DOI: 10.1039/ d1cy00039j ‡ These authors contributed equally. Published on 21 January 2021. Downloaded by Oklahoma State University on 11/16/2022 5:33:06 PM. View Article Online View Journal | View Issue

- 2. Catal. Sci. Technol., 2021, 11, 2414–2421 | 2415 This journal is © The Royal Society of Chemistry 2021 conducted via homogeneous palladium-catalyzed and copper- catalyzed coupling reactions in the presence of ligands and external oxidants.45 There is a critical need in the field to de- velop earth-abundant metal or metal oxide nanocatalyst- mediated reactions for the synthesis of conjugated polymers. Herein, we demonstrate the synthesis of poly- phenylenediethynylenes in moderate to high isolated yields using Cu2O NPs under ligandless and atmospheric condi- tions, where air is the oxidant. We also show that the Cu2O NPs under C–C coupling conditions undergo substrate- induced leaching to form homogeneous copper catalytic spe- cies. The leaching from Cu2O nanoparticles and the corre- sponding in situ formation of homogeneous Cu complexes under the C–C coupling conditions are confirmed and char- acterized using electrospray ionization mass spectrometry (ESI-MS), ultraviolet-visible (UV-vis) extinction spectroscopy, transmission electron microscopy (TEM) and reactor study. Our results confirm the homogeneous catalytic pathway con- tribution to the oxidative C–C homocoupling reactions inves- tigated in this study. Experimental section Cu2O nanoparticle synthesis The copper(I) oxide (Cu2O) spherical nanoparticles were syn- thesized using a microemulsion technique.46 The reaction medium was a water in n-heptane (99% Fisher, cat. no. AC447070025) emulsion with 0.1 M copper(II) nitrate (99.999%, Sigma-Aldrich, cat. no. 229636) solution in deion- ized water as precursor, which was reduced by 1 M aqueous hydrazine solution. Polyethylene glycol-dodecyl ether (Brij-L4 average Mn ∼ 362, Sigma-Aldrich, cat. no. 235989) was used as a surfactant. The reducing agent to precursor molar ratio was kept at 10 equivalents. The reaction was kept under con- tinuous stirring at room temperature for 12 h. At the end of the reaction, the solution was transferred into the centrifuge tube where acetone (99.5% Fisher, cat. no. MFCD00008765) was added to break the emulsion. The nanoparticles were sep- arated from the remaining solution through centrifugation at 3750 rpm for 20 minutes. The nanoparticles were washed four times with acetone to remove the surfactant and separated from the solution using the centrifuge, and the nanoparticles were further used to perform the C–C homocoupling reac- tions. The TEM image of the as-prepared Cu2O nanoparticles (diameter = 34 ± 4 nm) is shown in ESI† Fig. S2a.34,47 Characterization of Cu2O nanoparticles Ultraviolet-visible (UV-vis) extinction spectroscopy. UV-vis extinction spectra were measured using an Agilent Cary 60 spectrophotometer. For as-prepared Cu2O nanoparticle char- acterization, the data sampled for extinction spectra measure- ments were from 1100–200 nm, with a resolution of 0.5 nm and a scan speed of 300 nm min−1 . An aliquot of 150 μL was taken from the reaction mixture and diluted into 2 mL of eth- anol (100%, Fisher Scientific, cat no. BP2818100). The finite- difference time-domain simulation method was used to pre- dict and confirm the UV-vis extinction spectrum of the Cu2O nanoparticles obtained from the microemulsion synthesis method. The optical properties of Cu2O were taken from the Handbook of Optical Constants of Solids by Palik.48 Total-field/ scattered-field formalism was used for the simulations with illuminating source in the wavelength range 300–8000 nm. Perfectly matched layer boundary conditions were used in the simulations and the mesh size was fixed at 0.5 nm in all three dimensions. Both the experimental and computation- ally generated extinction spectra match well with each other, as shown in ESI† Fig. S2b. The UV-vis extinction spectra shown in ESI† Fig. S2b is unswerving with the band gap (i.e., 2.1 eV) of Cu2O. For the UV-vis extinction spectra measure- ments of the reaction mixture, an aliquot of 100 μL was taken from the reaction mixture and diluted into 2 mL of ethanol (100%, Fisher Scientific, cat. no. BP2818100). The sample was further diluted by mixing 600 μL of this aliquot in 3 mL of ethanol, which was then used for UV-vis extinction measurements. X-ray diffraction (XRD). Cu2O nanoparticles were obtained from the microemulsion synthesis. The powdered sample was used for sample preparation over the XRD sample holder. The XRD pattern of Cu2O nanoparticles was attained using a Philips X-ray diffractometer (Phillips PW 3710 mpd, PW2233/20 X-ray tube, copper tube detector: wavelength, 1.5418 Å) operating at 45 kW and 40 mA. The measured XRD pattern was used to confirm the Cu2O phase of the as- prepared nanospheres, as shown in ESI† Fig. S2c.34,47 Transmission electron microscopy (TEM). For TEM imag- ing, an aliquot of 100 μL of the reaction mixture was diluted in 2 mL of ethanol. The sample was sonicated for 1 min to break up any agglomeration of nanoparticles in solution. This sample (10 μL) was then taken and put onto the supported TEM grid as a single droplet. The sample was allowed to dry in air for approximately 5–10 minutes. The TEM measurements were performed on a JEOL-2100 spectro- meter. The accelerating voltage was 200 kV with a LaB6 gun. Oxidative homocoupling of phenylacetylene Cu2O NPs synthesized by the microemulsion technique discussed above (32 mg, 0.598 mmol) were suspended in di- methylformamide (DMF) (15 mL) prior to starting the reac- tion. This mixture was added to a 25 mL three-neck round- bottomed flask provided with a thermocouple and condenser. Potassium carbonate (Sigma-Aldrich, cat. no. MFCD00011382) (207 mg, 1.64 mmol) followed by 0.91 mmol of phenylacetylene (Sigma-Aldrich, cat. no. MFCD00008570) were then added to the reaction mixture. Air was continu- ously flowed through flask. The reaction mixture was then heated for 15 min until it reached 110 °C. For gas chromatography-mass spectrometry (GC-MS) analysis, 100 μL of the reaction mixture was sampled and diluted in 10 mL of dichloromethane (Fisher Scientific, cat. no. MFCD00000881). The reaction mixture was sampled at frequent time inter- vals to quantify the phenylacetylene (PA) conversion. A Catalysis Science & Technology Paper Published on 21 January 2021. Downloaded by Oklahoma State University on 11/16/2022 5:33:06 PM. View Article Online

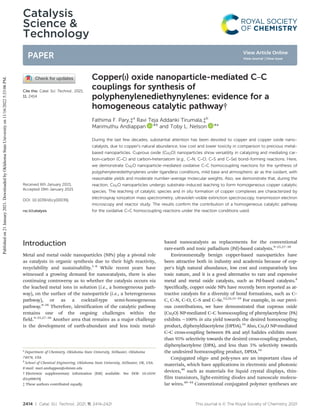

- 3. 2416 | Catal. Sci. Technol., 2021, 11, 2414–2421 This journal is © The Royal Society of Chemistry 2021 Shimadzu C184-E037A GC Column (phase: SH-Rxi™-5Sil MS column: length, 30 m; internal diameter, 25 mm; df, 0.25 μm) was used for gas chromatography in a Shimadzu QP2010SE GC-MS instrument. The column had an operating temperature range of −60 °C to 350 °C. Peak detection and integration of reactants and product were handled by the software provided by Shimadzu Corporation. Identification was also verified using NIST spectral libraries. The calibra- tion curves were built independently using area versus con- centration response from prepared reference samples. The PA conversion was calculated based on the equation shown below: Conversion X; % ð Þ ¼ CA0 − CA CA0 × 100 where CA0 is the initial concentration (in mmol) of reactant (i.e., PA) and CA is the concentration at any time, t. Homocoupling reaction with nitrogen and air switch conditions DMF was degassed with N2 for 6 hours for the removal of oxy- gen. Cu2O nanoparticles were suspended in N2-sparged DMF (15 mL) prior to starting the reaction (32 mg, 0.598 mmol). The reaction mixture was heated to 147 °C (reflux conditions) to minimize the dissolved oxygen content in the solvent and blanked with N2 flow. Phenylacetylene (0.91 mmol) was added to the reaction mixture. The reaction could proceed under these conditions for 20 hours and observed minimal (2–6%) conversion of the reactant, as shown in Fig. 1a. The reaction temperature was brought down to 110 °C and then airflow was used instead of N2 gas for blanketing the reaction mixture. The conversion increased rapidly and all of the reac- tion was completed in an hour at the end of cycle 1 (Fig. 1a). Cycle 2 reaction conditions. To ensure further activity of the catalyst, the reactant, i.e. phenylacetylene (0.91 mmol), and potassium carbonate (207 mg, 1.64 mmol) were added to the spent reaction mixture from cycle 1. The temperature was kept at 110 °C and airflow continued to blanket the reaction mixture. Complete conversion was obtained after 4 hours of reaction time, as shown in Fig. 1b. Polymer synthesis and characterization Materials for polymer synthesis. All reagents were pur- chased and used as received from Fisher Scientific and VWR, unless otherwise noted. Solvents were purchased from Fisher Scientific and used without further purification. The mono- mers, 2,5-dialkoxy-1,4-phenylenediethynylenes, were synthe- sized according to the literature.49 NMR experiments were performed with a I400 Bruker NMR instrument with CDCl3 as solvent. All spectra were referenced to δ 7.26 for the resid- ual chloroform solvent peak. Number-average molecular weight (Mn) and polydispersity (Đ) were determined by gel permeation chromatography using a Waters pump with a Wa- ters 2410 refractive index detector. Tetrahydrofuran was used Fig. 1 (a) Conversion as a function of reaction time for homocoupling reaction of PA at 110 °C, where the gas was switched from N2 to dry air after 20 hours of reaction time in cycle 1. (b) Conversion as a function of reaction time for homocoupling of PA at 110 °C for the second cycle, where the gas used was continued as dry air after the end of the first cycle. (c) UV-vis spectra for the homocoupling reaction of PA at 110 °C, where the gas was switched from N2 to dry air after 20 h of reaction time for cycle 1. (d) UV-vis spectra for homocoupling reaction of PA at 110 °C in the presence of base for cycle 2, where the gas was continued as dry air after the end of the first cycle. (e) Extinc- tion position for the homocoupling reaction of PA at 110 °C in the presence of base, where the gas was switched from N2 to dry air after 20 hours of reaction time for cycle 1. (f) Extinction position for homo- coupling reaction of PA at 110 °C in the presence of base for cycle 2, where the gas was continued as dry air after the end of first cycle. Catalysis Science & Technology Paper Published on 21 January 2021. Downloaded by Oklahoma State University on 11/16/2022 5:33:06 PM. View Article Online

- 4. Catal. Sci. Technol., 2021, 11, 2414–2421 | 2417 This journal is © The Royal Society of Chemistry 2021 as eluent with a flow rate of 1.0 mL min−1 at 35 °C. Polysty- rene standards were used for the calibration. Representative polymer synthesis procedure. (1,4-Bis((2- ethylhexyl)oxy)-2,5-di(prop-1-yn-1-yl)benzene) (0.065 mmol) and K2CO3 (0.26 mmol) were weighed in air then added to a 10 mL reaction vessel equipped with a stir bar. A suspension solution was prepared by adding Cu2O NPs (0.033 mmol, 50 mol%) in DMF (2.5 mL) and sonicated for 15 min. This sus- pension solution was added to the reaction vessel in air and the reaction vessel was sealed. Note: similar results were obtained in the presence of wet air, dry air or atmospheric air in the headspace of the reaction vessel. The reaction mix- ture was heated at 110 °C for 48 h then cooled to room tem- perature and precipitated in methanol (25 mL). The precipi- tate was filtered through a cellulose thimble and subjected to Soxhlet extraction with methanol, acetone and chloroform. The polymer was isolated and dried under reduced pressure to yield a dark brownish-red polymer (12 mg, 50%). 1 H NMR (400 MHz, CDCl3, δ) 6.96 (s, broad, Ar–H), 3.87 (d, broad, –OCH2), 1.79 (m, broad, –CH), 1.54–1.25 (m, broad, –CH2), 0.96 (t, broad, –CH3), 0.92 (t, –CH3). Mn = 8.6 kDa, PDI = 2.1. High-resolution electrospray ionization mass spectrometry (HR-ESI-MS). HR-ESI-MS spectra of the supernatant solution of the reaction mixture were collected on an LTQ Orbitrap sys- tem with an ESI source. The spray voltage was set at 5.0 kV with a 15.0 mL min−1 sample flow rate. To attain proper spraying conditions, the sample was prepared by mixing 1 mL of sample with 1 mL of a mixture of 18 mL dichloromethane, 2 mL acetone and 400 μL deionized water. The sample was sprayed with nitrogen as the sheath and auxiliary gas. Results and discussion In our previous contribution, we reported the catalytic path- ways of the Cu2O nanoparticle-mediated carbon–carbon (C– C) homocoupling reaction of a simple terminal alkyne sub- strate, i.e., phenylacetylene (PA).34 Specifically, we demon- strated that in the presence of a base (i.e., K2CO3), the Cu2O nanoparticles catalyze the homocoupling of phenylacetylene (PA) via a homogeneous catalytic pathway. A summary of these findings and the representative results are provided in Fig. S1 in the ESI.† In this contribution, we show that the findings demonstrated using a simple terminal alkyne sub- strate (i.e., PA) are transferrable to more complex substrates, i.e., 2,5-dialkoxy-1,4-phenylenediethynylenes. In this contribu- tion, we have also investigated in detail the role of oxygen and of the solvent in the Cu2O nanoparticle-mediated C–C homocoupling of phenylacetylene. Role of oxygen in Cu2O NP-mediated C–C homocoupling reaction To investigate the role of oxygen in the C–C homocoupling of terminal alkynes, we first carried out C–C homocoupling of phenylacetylene in the presence of a nitrogen environment (pu- rity >99.999%). The representative results are shown in Fig. 1a–f. As seen from Fig. 1a, in the first 20 hours the reaction progress was very slow in the absence of oxygen in the reaction mixture. Under the same conditions, the homogeneous com- plexes were still formed, even in the absence of oxygen, as evidenced from UV-vis extinction spectra of the homogeneous complexes in Fig. 1c and e. The peaks at ∼385 and ∼450 nm in the extinction spectra are associated with homogeneous Cu cat- alytic species [CuO(C8H5)2]− and [CuO(C8H5)2·H2O]− (see Fig. S1 and the description in the ESI† for more details). The presence of homogeneous Cu complexes [CuO(C8H5)2]− and [CuO(C8- H5)2·H2O]− was also confirmed using ESI-MS analysis of the supernatant solution of the reaction mixture, as shown in Fig. S1c.† The ESI-MS was used to analyze the structure of the Cu complex, [CuO(C8H5)2]− , and suggested that two PA (C8H6) mole- cules first adsorb onto the surface of Cu2O NPs (i.e., one mole- cule on a surface Cu atom and another molecule on a neighbouring surface O atom), and subsequently cause leaching of Cu and O surface atoms. The second complex, [CuO(C8- H5)2·H2O]− , can then form from the first complex, [CuO(C8- H5)2]− , and a water (H2O) molecule, which is the expected by- product of oxidative C–C homocoupling of terminal alkynes. In summary, the representative results shown in Fig. 1 confirm that the oxygen atom present in the homogeneous complexes [CuO(C8H5)2]− and [CuO(C8H5)2H2O]− was formed from the sur- face oxygen atoms of the Cu2O nanoparticles. In Fig. 1a, when oxygen (in the form of air) was introduced into the reaction mixture at ∼20 hours, the reaction progress was relatively faster and complete conversion occurred as expected. These results confirmed that, although the homo- geneous Cu catalytic species can be formed in the absence of oxygen, homogeneous Cu species can catalyze the C–C homo- coupling reaction only in the presence of oxygen. For the second cycle, the same quantity of reactant (PA) was charged to the reaction mixture, and the reaction was allowed to start, at ∼22 hours in Fig. 1a. In the presence of oxygen, complete conversion was again achieved. The evi- dence for the homogeneous complexes formed during the second cycle can also be evidenced by Fig. 1d and f. The UV- vis extinction peak appearances of homogeneous Cu com- plexes in Fig. 1d and f are similar to the homocoupling reac- tion conditions shown in Fig. S1.† These results provide evi- dence of rejuvenation of catalyst activity, and formation of the homogeneous complexes from the spent Cu2O nano- particles. Similar to results shown in Fig. S1,† in Fig. 1e and f, the concentration of homogeneous Cu com- plexes increases initially, and then decreases as the reactant (PA) is depleted with time. A similar pattern was observed in the peak position, with time, as shown in Fig. S4a and S4b† at the end of the reaction cycle. These trends confirm that the homogeneous Cu complexes are indeed participating in the catalytic cycle. Role of solvent To investigate the role of solvent on the rate of the homo- coupling reaction, we investigated the reaction using Cu2O spheres in the presence of DMF, acetonitrile and ethanol at Catalysis Science & Technology Paper Published on 21 January 2021. Downloaded by Oklahoma State University on 11/16/2022 5:33:06 PM. View Article Online

- 5. 2418 | Catal. Sci. Technol., 2021, 11, 2414–2421 This journal is © The Royal Society of Chemistry 2021 the reaction temperature of 70 °C. Ethanol and acetonitrile are comparatively greener solvents than DMF.50,51 The repre- sentative results are shown in Fig. 2. As seen from Fig. 2a, similar catalytic activity is observed using the three solvents. The representative UV-vis extinction spectra of homogeneous Cu complexes observed in the experiment using ethanol as the solvent are shown in Fig. 2b. The results shown in Fig. S1† and 1 and 2 are performed in DMF. As seen from the UV- vis extinction spectra shown in Fig. S1† and 1 and 2, the homogeneous Cu complexes and their peak positions are similar in DMF and ethanol. These results confirm that the degree of leaching and formation of homogeneous Cu com- plexes does not strongly depend on the nature of the solvent. Instead, the substrate-induced (phenylacetylene, PA) leaching mainly depends on the size and shape of the Cu2O nanoparticles. Polymerization of 2,5-dialkoxy-1,4-phenylenediethynylenes To understand the broad application of this methodology, we also investigated Cu2O NP-mediated polymerization of 2,5-dialkoxyphenylene-1,4-diethynylenes via the oxidative homocoupling reaction (OHR) (Scheme 1) with reasonable yields and moderate number-average molecular weight (Mn) values. The utilization of air as the oxidant and ligand-free conditions of the Cu2O NPs led to a cost effective and envi- ronmentally friendly process that is applicable for industrial- scale synthesis. Our polymerization journey was started by using 1,4-bis(dodecyloxy)-2,5-di(prop-1-yn-1-yl)benzene as the mono- mer. Initially, we employed K2CO3 (2 eq.) and Cu2O NPs (50 mol%) in DMF. As mentioned above, although the reactivity of C–C homocoupling was similar in greener solvents, such as ethanol and acetonitrile, DMF was selected to enhance the re- sultant polymer solubility in the reaction medium. In the pres- ence of two equivalents of K2CO3, the reaction resulted in poly- mer 1a with low molecular weight and 70% yield. Thus, we increased the amount of base to four equivalents on the basis of previously reported polymerizations52 (Table 1, entry 1). The desired polymer was obtained in good yield (88%) but still with a low Mn value of 1.1 kDa. Additional base (16 eq.; Table 1, en- try 2) was needed to improve the Mn value to 3.3 kDa. Then, we sought to probe the catalyst loading (Table 1, en- tries 2–4). Lower catalyst loading resulted in a significant low- ering of yield. For example, catalyst loadings of 25 mol% and 5 mol% resulted in yields of 33% and 25%, respectively, with a slight decrease in Mn values (entries 3 and 4). In general, relatively low Mn values were observed for the polymers shown in Table 1 (entries 1–4), which can probably be attrib- uted to the poor polymer solubility in DMF. Indeed, the reac- tion mixture became opaque as the reaction proceeded and deposition was observed on the wall of the reaction vessel, which could result in a heterogeneous reaction and hin- drance of the step-growth polymerization. Considering these Fig. 2 (a) Conversion as a function of reaction time for the homocoupling reaction of PA at 70 °C in the presence of air in various solvents, catalyzed by Cu2O nanoparticles. (b) Extinction spectra for the homocoupling reaction of PA at 70 °C in the presence of air in ethanol (greener solvent). Scheme 1 Synthesis of poly(2,5-dialkoxy-1,4-phenylenediethynylenes). Table 1 Optimization of Cu2O NP-mediated polymerization for 1a via the OHR Entry Cu2O NPs (mol%) K2CO3 (eq.) Solvent Yield (%) Mn (Da) Đ 1 50 4 DMF 88 1080 1.4 2 50 16 DMF 75 3340 1.6 3 5 16 DMF 25 1588 1.3 4 25 16 DMF 33 2280 1.2 5 50 16 DMF/DCB 90 3012 1.6 Catalysis Science & Technology Paper Published on 21 January 2021. Downloaded by Oklahoma State University on 11/16/2022 5:33:06 PM. View Article Online

- 6. Catal. Sci. Technol., 2021, 11, 2414–2421 | 2419 This journal is © The Royal Society of Chemistry 2021 results, we anticipated that the addition of 1,4 dichloroben- zene (DCB) would improve the solubility (Table 1, entry 5). Unfortunately, deposition on the reaction vessel was still ob- served, and the Mn values remained low (3.0 kDa). The poly- dispersity (Đ) values outlined in Table 1, entries 1–5, have a range from 1.2 to 1.6, and these values are expected for poly- condensation reactions.45 In an attempt to enhance the solubility, a second polymer derivative was prepared that incorporated branched ethyl- hexyloxy side chains. The data for polymer 1b are summa- rized in Table 2. In contrast to the dodecyloxy analogue, 1a, poly(1,4-bis((2-ethylhexyl)oxy)-2,5-di(prop-1-yn-1-yl)benzene), 1b, afforded higher Mn values ranging from 5 to 11 kDa (Table 2, entries 1–5) and in all cases large polydispersities were observed. Similarly, large polydispersities were also reported in the literature for these types of polymers.45 The polymer yields obtained were comparatively lower than for 1a (Table 2, entries 1–5). However, we observed yellowish-red material that remained in the Soxhlet thimble, which we as- sume to be insoluble higher molecular weight polymer. As mentioned earlier, structure characterization was done using 1 H NMR spectroscopy and the spectra were in good agree- ment with those previously reported.45 It can be concluded that Cu2O NP-mediated polymerization by oxidative homo- coupling reactions can be achieved under ligandless atmo- spheric conditions without the addition of external oxidants. Incorporation of branched alkoxy side chains increased the solubility of the polymers in DMF. Consequently, the molecu- lar weights of the products were improved. Possible intermediate copper complexes To obtain insight into the signatures of the homogeneous Cu complexes responsible for catalyzing the polymerization reac- tions, we also performed HR-ESI-MS analysis of the superna- tant solution obtained from the polymerization reactions. The representative HR-ESI-MS spectra of complexes observed in polymerization samples are shown in Fig. 3a–c. The pre- dicted mass spectra for the Cu complexes observed in homo- coupling of PA and the polymerization reactions are shown in Fig. S5a, b and S6a–c, respectively, in the ESI.† Based on the experimentally observed and predicted HR-ESI-MS spec- tra, we proposed structures for the Cu complexes and these structures are shown in Fig. 4a–c. Based on the HR-ESI-MS spectrum of the complex ob- served in the polymer sample shown in Fig. 3a, we propose the copper complex with the structure shown in Fig. 4a for the polymerization reaction of 1a. In accordance with the ex- perimental spectra in Fig. 3b and c, we propose two possible homogeneous Cu complexes, as shown in Fig. 4b and c, for the polymerization reaction of 1b. In this case, the experi- mental spectra showed a best match with the predicted spec- tra shown in ESI† Fig. S6b and c. It is worth mentioning here that, although we propose the structures in Fig. 4a–c based on HR-ESI-MS results, the actual homogeneous Cu catalytic Table 2 Optimization of Cu2O NP-mediated polymerization for 1b via the OHR Entry Cu2O NPs (mol%) K2CO3 (eq.) Solvent Yield (%) Mn (Da) Đ 1 50 4 DMF 50 8585 2.1 2 50 16 DMF 40 9022 4.5 3 5 16 DMF 25 5424 1.7 4 25 16 DMF 40 9796 4.5 5 50 16 DMF/DCB 48 11 204 3.8 Fig. 3 (a) The HR-ESI-MS spectrum measured in negative-spray mode for the supernatant solution of the reaction mixture taken from poly- mer 1a. (b and c) The HR-ESI-MS spectrum measured in negative- spray mode for the supernatant solution of the reaction mixture taken from polymer 1b. Catalysis Science & Technology Paper Published on 21 January 2021. Downloaded by Oklahoma State University on 11/16/2022 5:33:06 PM. View Article Online

- 7. 2420 | Catal. Sci. Technol., 2021, 11, 2414–2421 This journal is © The Royal Society of Chemistry 2021 species present in the solution phase may be more complex than the species detected by HR-ESI-MS. Conclusion and consequences Using various characterization techniques, such as GC-MS, UV-vis extinction spectroscopy, ESI-MS and TEM, on the C–C homocoupling reaction, we have shown that Cu2O nano- particles can undergo leaching to form in situ homogeneous copper complexes. Air as an oxidant was required for homo- geneous complexes to catalyze the homocoupling reaction. The degree of leaching is independent of the solvents used in the study. Using Cu2O nanoparticle-mediated oxidative homo- coupling reactions, we have synthesized Cu2O nanoparticle- mediated poly(2,5-dialkoxy-1,4-phenylenediethynylene) under ligandless conditions and using naturally available air as oxi- dant. This methodology is environmentally benign and cost effective, in contrast to traditional methods. The addition of branched alkoxy side chains increases the solubility, thereby improving the molecular weight of the polymers. This proto- col can be applied to other conjugated polymer syntheses via oxidative homocoupling reactions. Conflicts of interest There are no conflicts to declare. Acknowledgements The research results disclosed in this publication were made possible in part by funding through the Oklahoma Center for the Advancement of Science and Technology (project number HR18-093) and the Alfred P. Sloan Foundation (project num- ber G10002819). The TEM images were acquired at the Okla- homa State University (OSU) Microscopy Laboratory. HR-ESI- MS spectra were acquired at the OSU DNA and Protein Core Facility. We are appreciative of Dr Steven Hartson for his as- sistance with HR-ESI-MS data analysis. We also thank Farshid Mohammadparast and Sundaram Bharadwaj Ramakrishnan for help with the review of the paper. Notes and references 1 N. K. Ojha, G. V. Zyryanov, A. Majee, V. N. Charushin, O. N. Chupakhin and S. Santra, Coord. Chem. Rev., 2017, 353, 1–57. 2 B. C. Ranu, A. Saha and R. Jana, Adv. Synth. Catal., 2007, 349, 2690–2696. 3 S. Wang, Z. Wang and Z. Zha, Dalton Trans., 2009, 9363. 4 M. B. Gawande, A. Goswami, F.-X. Felpin, T. Asefa, X. Huang, R. Silva, X. Zou, R. Zboril and R. S. Varma, Chem. Rev., 2016, 116, 3722–3811. 5 H. Cong and J. A. Porco, ACS Catal., 2012, 2, 65–70. 6 M. O. Sydnes, Curr. Org. Chem., 2014, 18(3), 312–326. 7 F. Mohammadparast, A. P. Dadgar, R. T. A. Tirumala, S. Mohammad, C. O. Topal, A. K. Kalkan and M. Andiappan, J. Phys. Chem. C, 2019, 123, 11539–11545. 8 F. Mohammadparast, R. Teja Addanki Tirumala, S. Bhardwaj Ramakrishnan, A. P. Dadgar and M. Andiappan, Chem. Eng. Sci., 2020, 225, 115821. 9 V. Farina, Adv. Synth. Catal., 2004, 346, 1553–1582. 10 N. T. S. Phan, M. Van Der Sluys and C. W. Jones, Adv. Synth. Catal., 2006, 348, 609–679. 11 A. Balanta, C. Godard and C. Claver, Chem. Soc. Rev., 2011, 40, 4973–4985. 12 M. B. Thathagar, J. Beckers and G. Rothenberg, J. Am. Chem. Soc., 2002, 124, 11858–11859. 13 S. Peiris, S. Sarina, C. Han, Q. Xiao and H.-Y. Zhu, Dalton Trans., 2017, 46, 10665–10672. 14 Q. Xiao, S. Sarina, A. Bo, J. Jia, H. Liu, D. P. Arnold, Y. Huang, H. Wu and H. Zhu, ACS Catal., 2014, 4, 1725–1734. 15 Nanocatalysis: Synthesis and Applications, ed. V. Polshettiwar, T. Asefa and G. Hutchings, 2013, https://www.wiley.com/en-us/ Nanocatalysis%3A+Synthesis+and+Applications-p-9781118148860, (accessed November 27, 2020). 16 P. Garcia, M. Malacria, C. Aubert, V. Gandon and L. Fensterbank, ChemCatChem, 2010, 2, 493–497. Fig. 4 Proposed copper-based homogeneous complexes for the polymerization reaction of 1a (a) and the proposed copper complexes for the polymerization reaction of 1b (b and c). Catalysis Science & Technology Paper Published on 21 January 2021. Downloaded by Oklahoma State University on 11/16/2022 5:33:06 PM. View Article Online

- 8. Catal. Sci. Technol., 2021, 11, 2414–2421 | 2421 This journal is © The Royal Society of Chemistry 2021 17 J. A. Widegren and R. G. Finke, J. Mol. Catal. A: Chem., 2003, 198, 317–341. 18 A. Biffis, M. Zecca and M. Basato, Eur. J. Inorg. Chem., 2001, 2001, 1131–1133. 19 A. F. Schmidt, A. Al-Halaiqa and V. V. Smirnov, Kinet. Catal., 2008, 49, 395–400. 20 M. B. Thathagar, J. E. ten Elshof and G. Rothenberg, Angew. Chem., Int. Ed., 2006, 45, 2886–2890. 21 P. J. Ellis, I. J. S. Fairlamb, S. F. J. Hackett, K. Wilson and A. F. Lee, Angew. Chem., Int. Ed., 2010, 49, 1820–1824. 22 A. M. Thomas, A. Sujatha and G. Anilkumar, RSC Adv., 2014, 4, 21688–21698. 23 Y.-Q. Zhang, N. Kepčija, M. Kleinschrodt, K. Diller, S. Fischer, A. C. Papageorgiou, F. Allegretti, J. Björk, S. Klyatskaya, F. Klappenberger, M. Ruben and J. V. Barth, Nat. Commun., 2012, 3, 1286. 24 H.-Y. Gao, H. Wagner, D. Zhong, J.-H. Franke, A. Studer and H. Fuchs, Angew. Chem., Int. Ed., 2013, 52, 4024–4028. 25 H.-Y. Gao, D. Zhong, H. Mönig, H. Wagner, P.-A. Held, A. Timmer, A. Studer and H. Fuchs, J. Phys. Chem. C, 2014, 118, 6272–6277. 26 M. V. Polynski and V. P. Ananikov, ACS Catal., 2019, 9, 3991–4005. 27 S. K. Beaumont, J. Chem. Technol. Biotechnol., 2012, 87, 595–600. 28 G. Kyriakou, S. K. Beaumont, S. M. Humphrey, C. Antonetti and R. M. Lambert, ChemCatChem, 2010, 2, 1444–1449. 29 Á. Molnár, Chem. Rev., 2011, 111, 2251–2320. 30 J. Zhao, E. Ding, A. M. Allgeier and L. Jia, J. Polym. Sci., Part A: Polym. Chem., 2003, 41, 376–385. 31 Copper-Mediated Cross-Coupling Reactions, ed. G. Evano and N. Blanchard, Wiley, 2013, https://www.wiley.com/en-us/ Copper+Mediated+Cross+Coupling+Reactions-p- 9781118060452, (accessed November 27, 2020). 32 M. Donnard and N. Blanchard, in Copper-Mediated Cross- Coupling Reactions, John Wiley & Sons, Ltd, 2013, pp. 683–723. 33 D. Pappo, in Copper-Mediated Cross-Coupling Reactions, John Wiley & Sons, Ltd, 2013, pp. 643–682. 34 R. T. Addanki Tirumala, A. P. Dadgar, F. Mohammadparast, S. B. Ramakrishnan, T. Mou, B. Wang and M. Andiappan, Green Chem., 2019, 21, 5284–5290. 35 F. Alonso, T. Melkonian, Y. Moglie and M. Yus, Eur. J. Org. Chem., 2011, 2011, 2524–2530. 36 F. Chahdoura, C. Pradel and M. Gómez, ChemCatChem, 2014, 6, 2929–2936. 37 C.-F. Lee, Y.-C. Liu and S. S. Badsara, Chem. – Asian J., 2014, 9, 706–722. 38 Y. S. Panova, A. S. Kashin, M. G. Vorobev and E. S. Degtyareva, ACS Catal., 2016, 3637–3643. 39 I. P. Beletskaya and V. P. Ananikov, Chem. Rev., 2011, 1596–1636. 40 A. Haque, R. A. Al-Balushi, I. J. Al-Busaidi, M. S. Khan and P. R. Raithby, Chem. Rev., 2018, 118, 8474–8597. 41 A. Broggi, I. Tomasi, L. Bianchi, A. Marrocchi and L. Vaccaro, ChemPlusChem, 2014, 79, 486–507. 42 S. Schmid, A. K. Kast, R. R. Schröder, U. H. F. Bunz and C. Melzer, Macromol. Rapid Commun., 2014, 35, 1770–1775. 43 D. Steiger, P. Smith and C. Weder, Macromol. Rapid Commun., 1997, 18, 643–649. 44 J. R. Matthews, W. Niu, A. Tandia, A. L. Wallace, J. Hu, W.-Y. Lee, G. Giri, S. C. B. Mannsfeld, Y. Xie, S. Cai, H. H. Fong, Z. Bao and M. He, Chem. Mater., 2013, 25, 782–789. 45 M. Kijima, I. Kinoshita, T. Hattori and H. Shirakawa, Synth. Met., 1999, 100, 61–69. 46 A. Marimuthu, J. Zhang and S. Linic, Science, 2013, 339, 1590–1593. 47 F. Mohammadparast, S. B. Ramakrishnan, N. Khatri, R. T. A. Tirumala, S. Tan, A. K. Kalkan and M. Andiappan, ACS Appl. Nano Mater., 2020, 3, 6806–6815. 48 E. Palik, Handbook of Optical Constants of Solids, 1998. 49 S. Selvaraju, K. A. N. Sachinthani, R. A. Hopson, F. M. McFarland, S. Guo, A. L. Rheingold and T. L. Nelson, Chem. Commun., 2015, 51, 2957–2959. 50 D. Prat, J. Hayler and A. Wells, Green Chem., 2014, 16, 4546–4551. 51 C. M. Alder, J. D. Hayler, R. K. Henderson, A. M. Redman, L. Shukla, L. E. Shuster and H. F. Sneddon, Green Chem., 2016, 18, 3879–3890. 52 R. M. Pankow, L. Ye and B. C. Thompson, ACS Macro Lett., 2018, 7, 1232–1236. Catalysis Science & Technology Paper Published on 21 January 2021. Downloaded by Oklahoma State University on 11/16/2022 5:33:06 PM. View Article Online