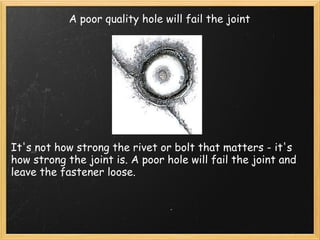

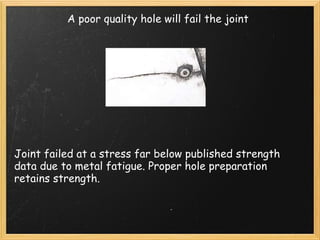

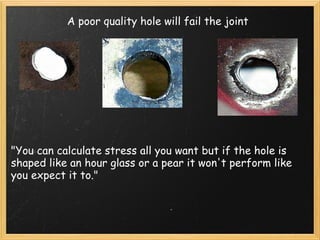

A poor quality hole will fail the joint and compromise the integrity and strength of the connection. Properly preparing holes through careful drilling, cleaning, sizing, and cold working is important for ensuring optimal fatigue strength and preventing premature failure. Mechanic's Toolbox Software provides tools and resources to help mechanics properly create holes.