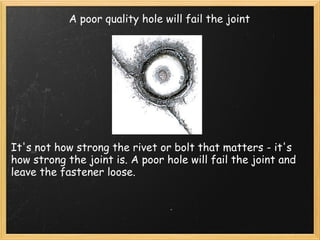

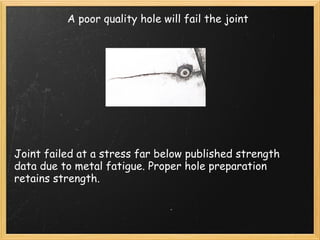

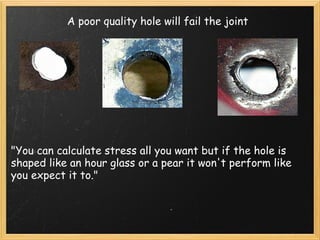

A poor quality hole will fail the aircraft joint. It does not matter how strong the rivet or bolt is if the hole is of poor quality. A poor hole can cause a loose fastener or metal fatigue and lead to joint failure at stress levels below specifications. Ensuring proper hole preparation, drilling speed and feed rate, cleaning, sizing, cold working, measuring, and plugging holes is important for maintaining optimal joint strength. The Mechanic's Toolbox software website provides tools and information to help mechanics efficiently produce quality holes.