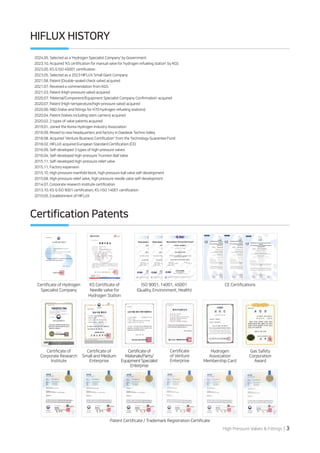

Hiflux Co., Ltd. specializes in high-pressure equipment and has established itself as a technological leader through extensive R&D, producing various high-pressure valves and fittings for diverse applications, including hydrogen fuel stations. The company has attained several certifications and patents and is recognized as a 'hydrogen specialist company' by the South Korean government, reflecting its commitment to innovation and carbon neutrality. Hiflux aims to grow as a global brand by developing advanced products and enhancing service quality while contributing to the hydrogen industry.