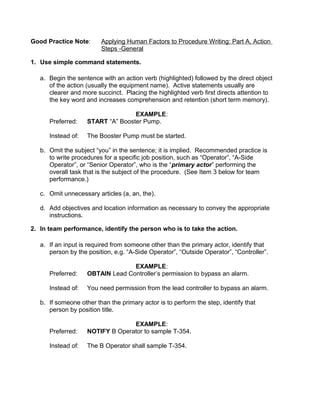

The document provides guidelines for writing clear and effective procedures. It recommends using simple active statements with action verbs and direct objects. It suggests identifying specific job positions responsible for actions. Steps should contain a single action and avoid hidden instructions. Lists of objects for an action should be vertical. Positive language is preferred over negative. Useful information can be added for context but should not overexplain trivial tasks.