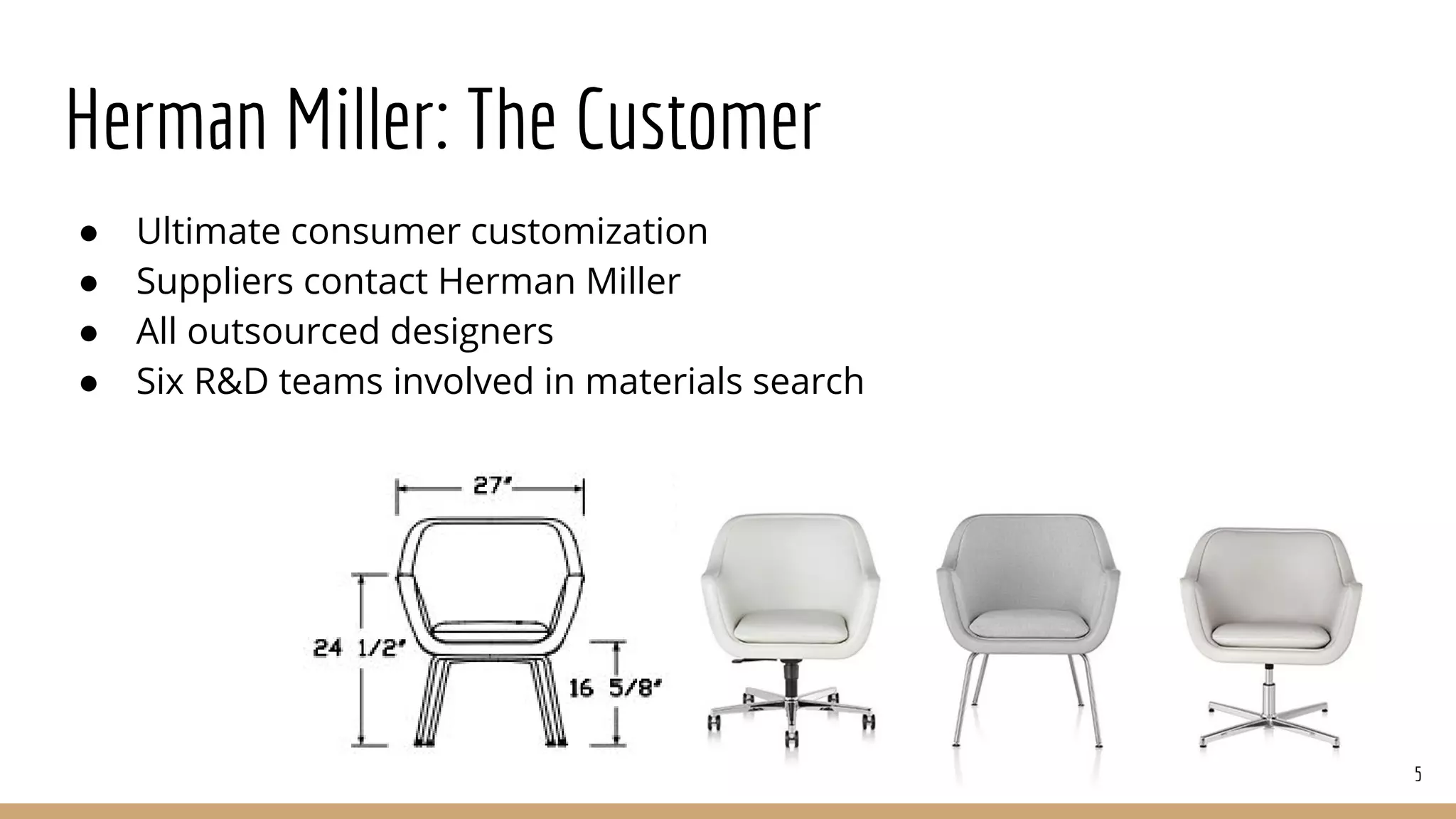

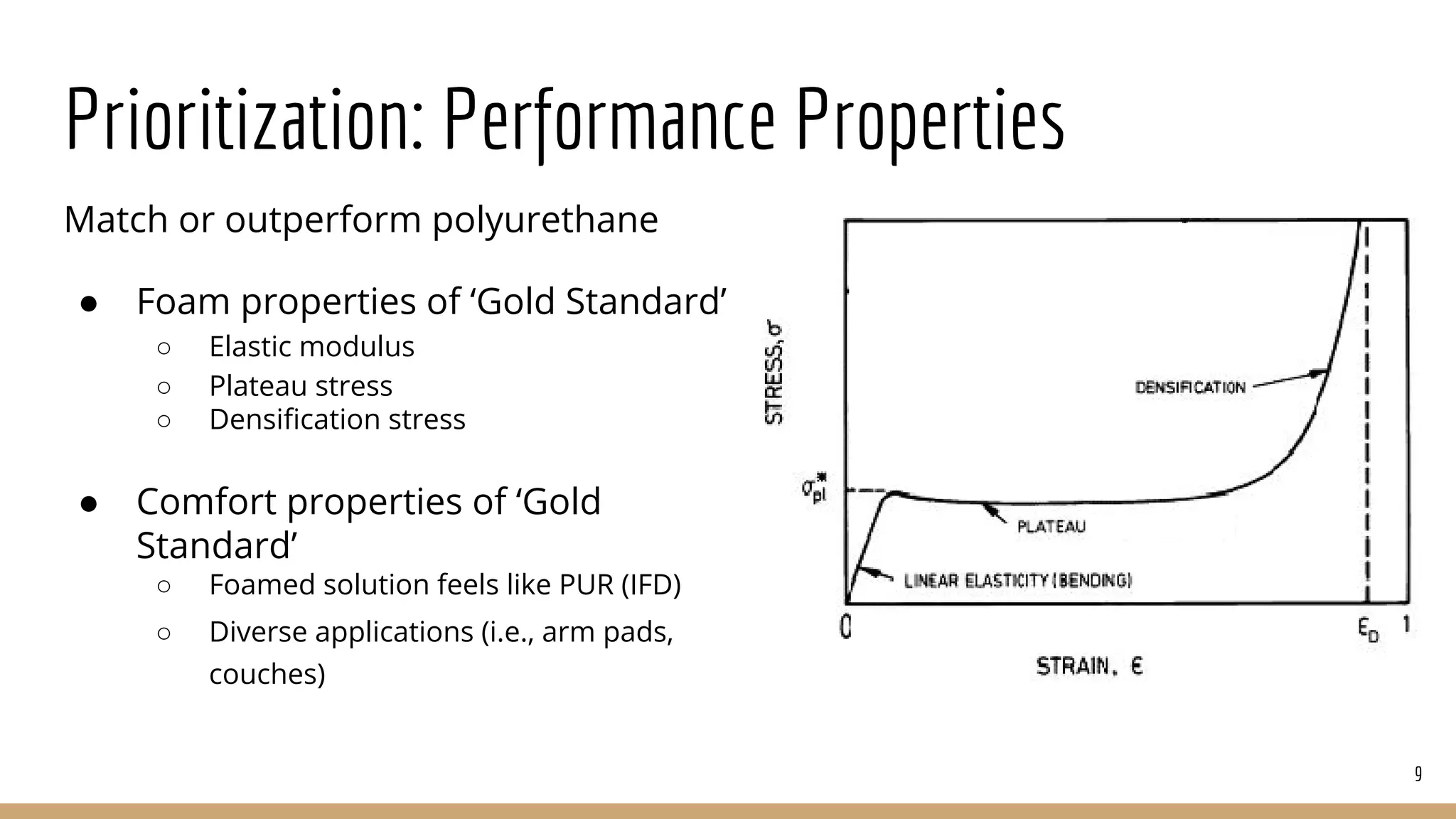

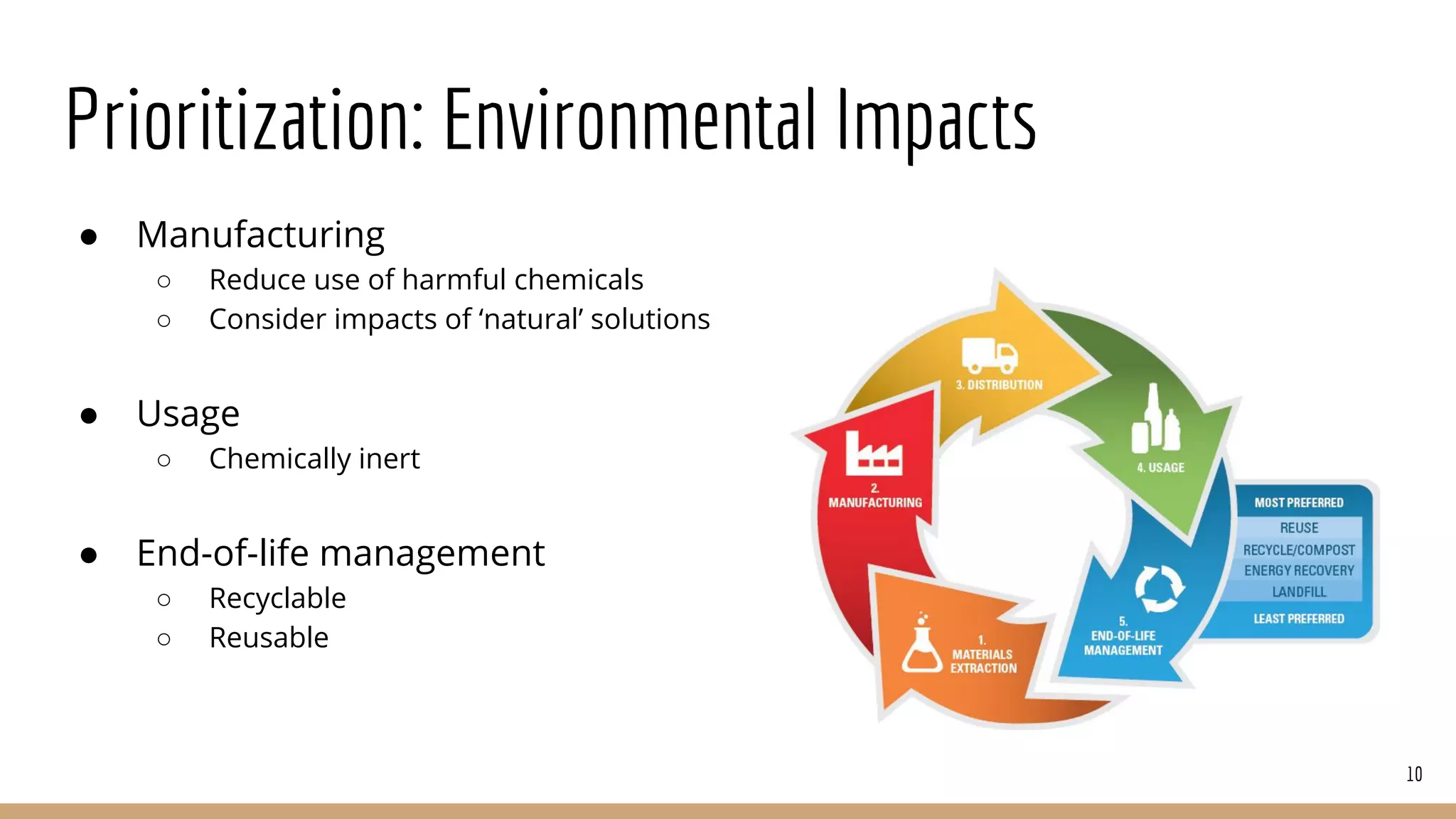

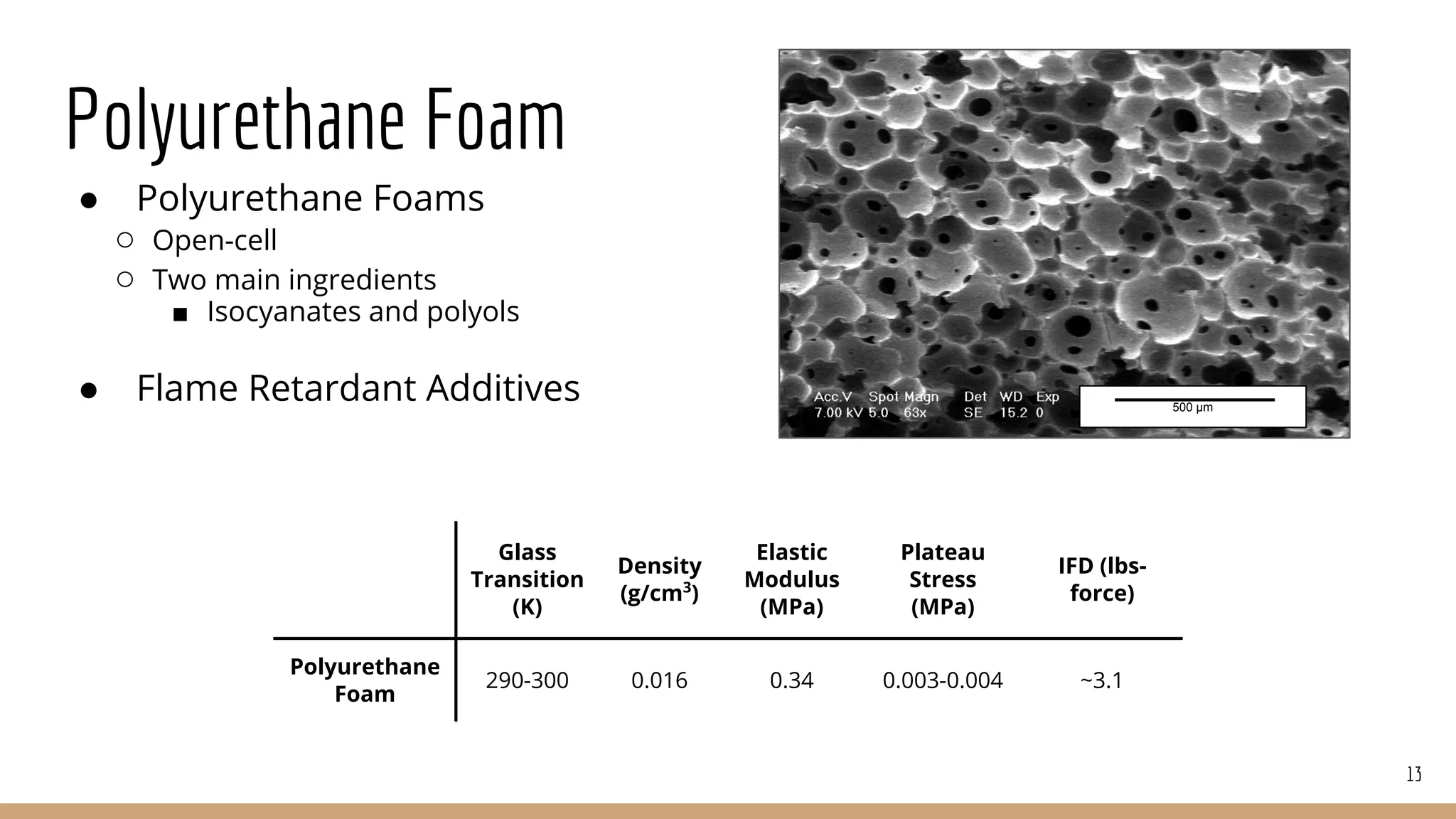

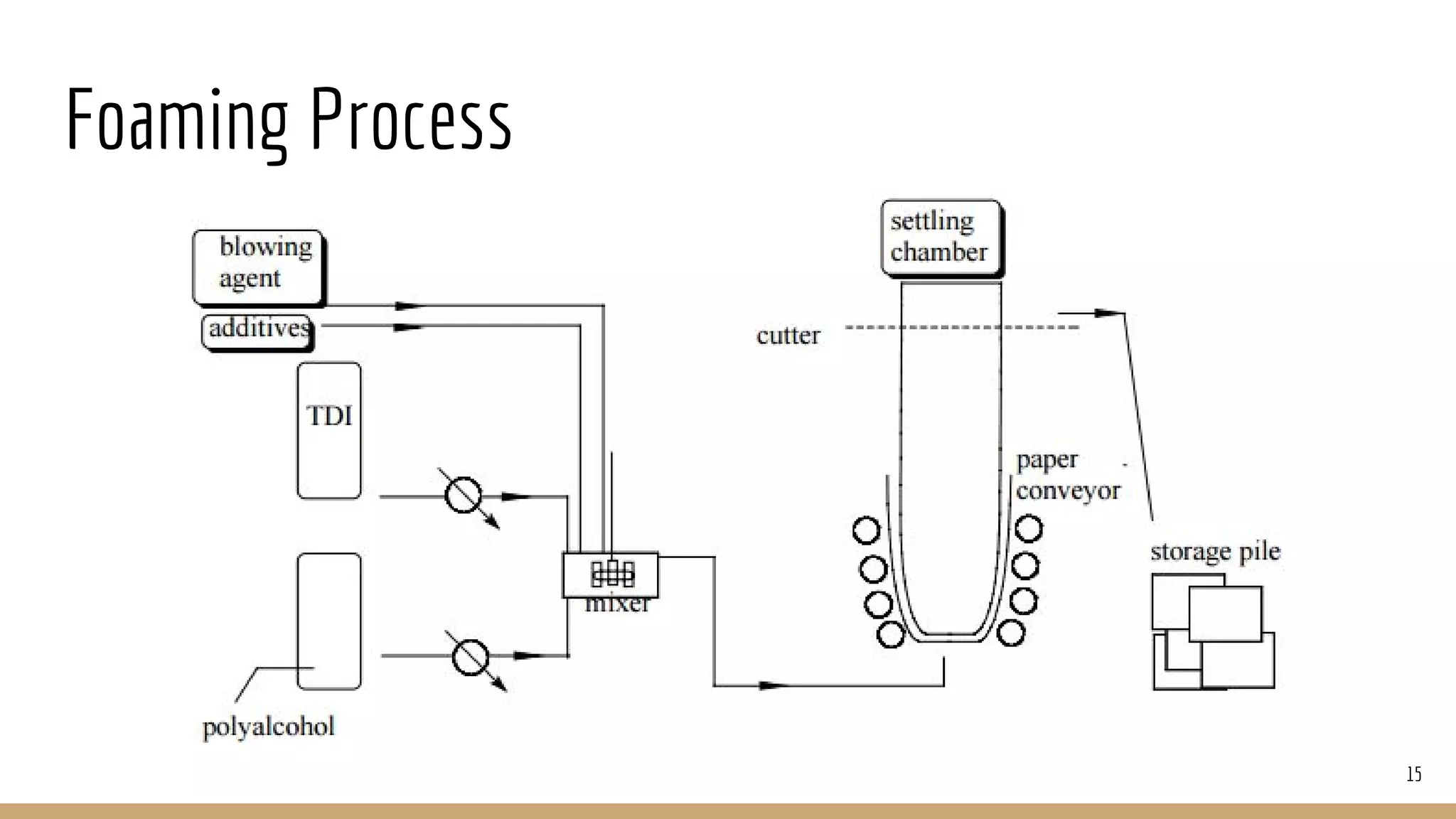

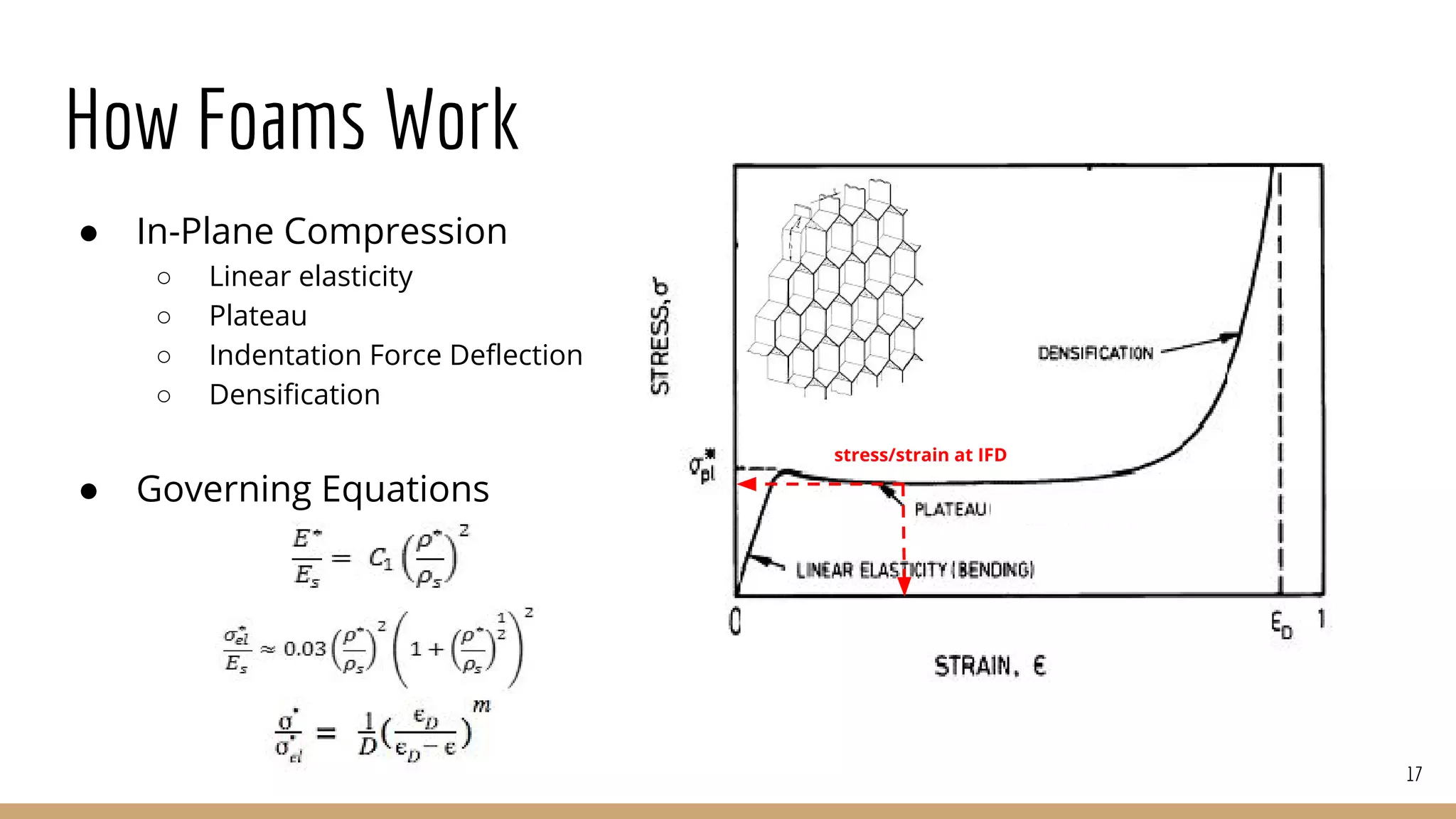

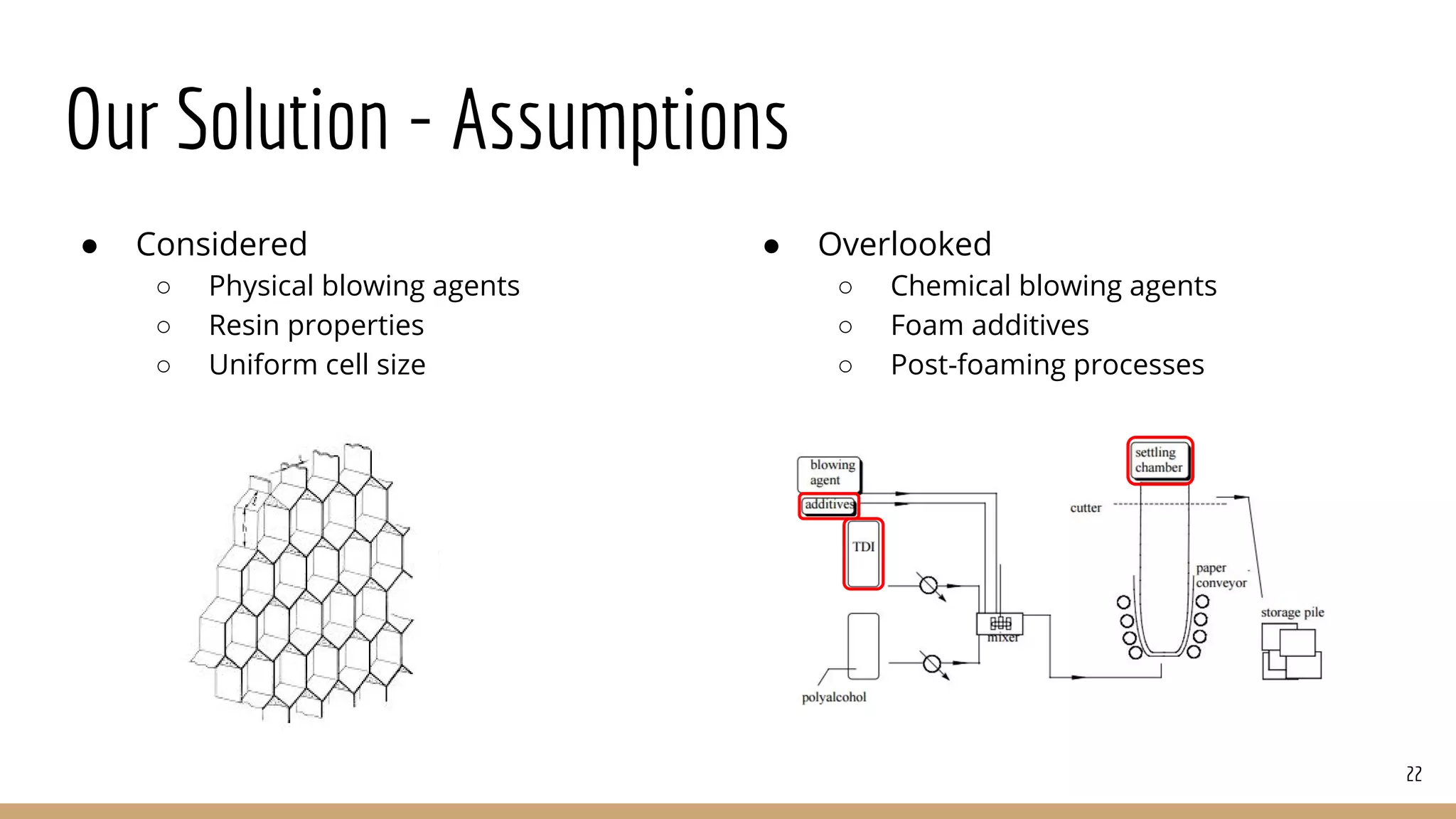

Herman Miller is looking for an alternative to polyurethane foam used in furniture. Polyurethane foam is considered the "gold standard" but has environmental drawbacks. The group developed a program to predict foam properties based on resin and processing parameters. However, the program has limitations since it does not fully account for chemical blowing agents, additives, and post-foaming processes. Additionally, no ideal resin alternative has been identified that can match polyurethane foam's performance while also addressing environmental concerns.