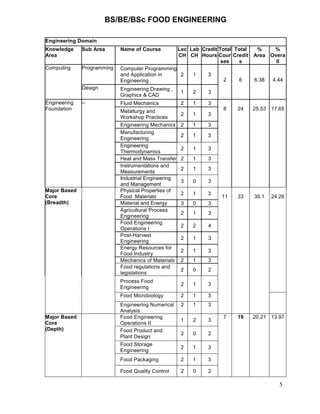

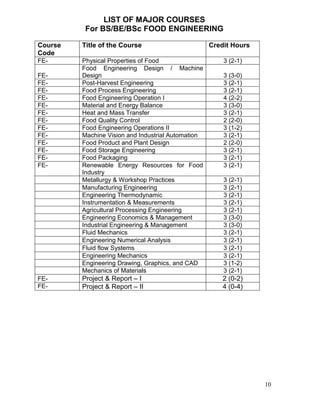

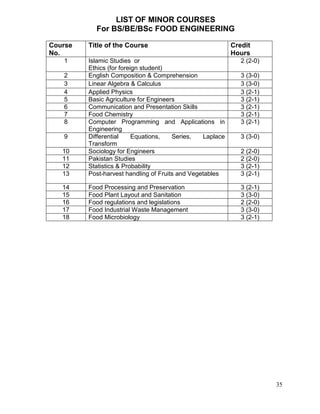

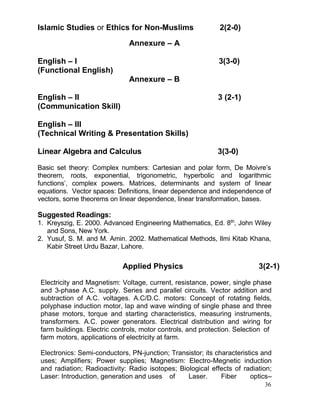

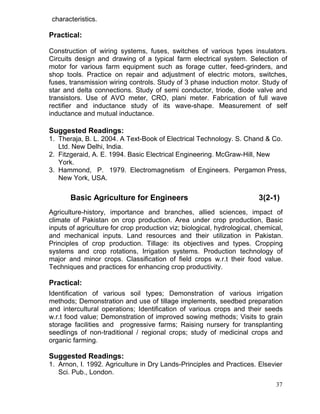

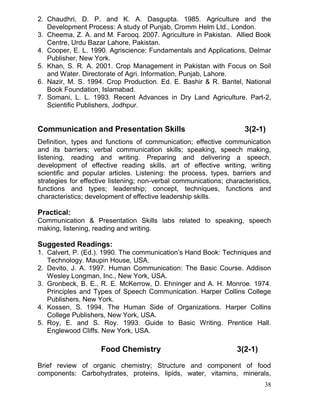

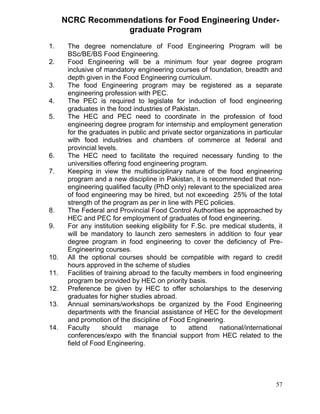

The document provides details of the curriculum for a 4-year BS/BE/BSc degree program in Food Engineering, including the program mission, vision, duration, credit hours, and course requirements. The curriculum aims to develop competency in food engineering to address issues related to food handling, processing, and value addition of agricultural products. The curriculum consists of 136 total credit hours, with 69.12% (94 credits) in engineering courses and 30.88% (42 credits) in non-engineering courses in areas like mathematics, basic sciences, social sciences, and management. The engineering courses cover breadth and depth areas in food engineering operations, post-harvest engineering, food processing, packaging, and plant design.