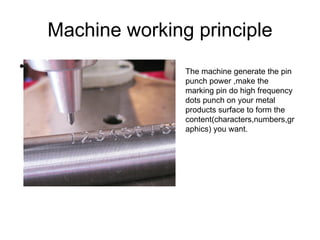

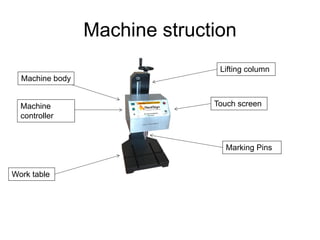

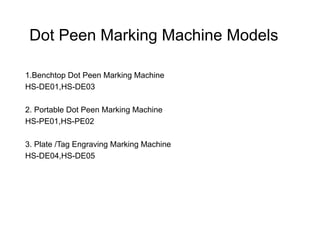

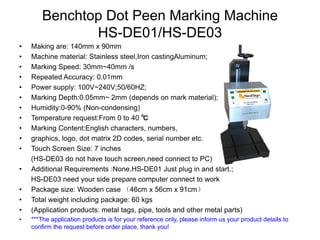

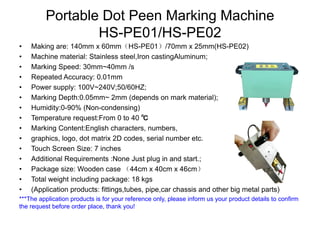

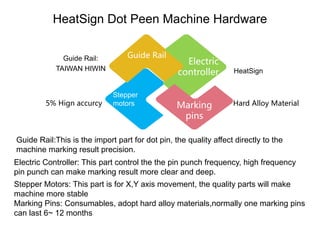

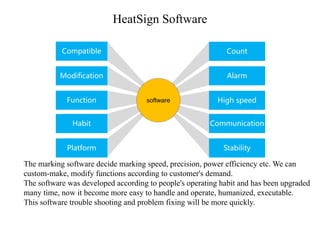

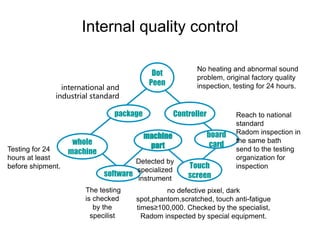

The document outlines the specifications and applications of various dot peen marking machines including benchtop, portable, and engraving models, suitable for marking on metals and some hard plastics. It emphasizes the machines' high marking speed, accuracy, and durability while detailing their construction, operational parameters, and application industries such as aerospace, automotive, and medical. The document also highlights the company's commitment to quality and customer service, insisting on high standards for the technology and components used in their machines.